A Monday-Morning Bottleneck That Feels Familiar

“Why does dispatch always choke right before cutoff?” the operations lead asked, staring at the dashboard.

“Because inbound is late again, pick paths are crossing, and charging is fighting for sockets,” the supervisor replied.

“So we fix dispatch?”

“We fix the system. Dispatch is just where the pain shows up.”

That’s the practical case for a One-Stop Magazijn approach: most bottlenecks aren’t single failures. They’re coordination failures—small issues stacked across receiving, storage, replenishment, picking, packing, and power management until the entire building behaves like a traffic jam.

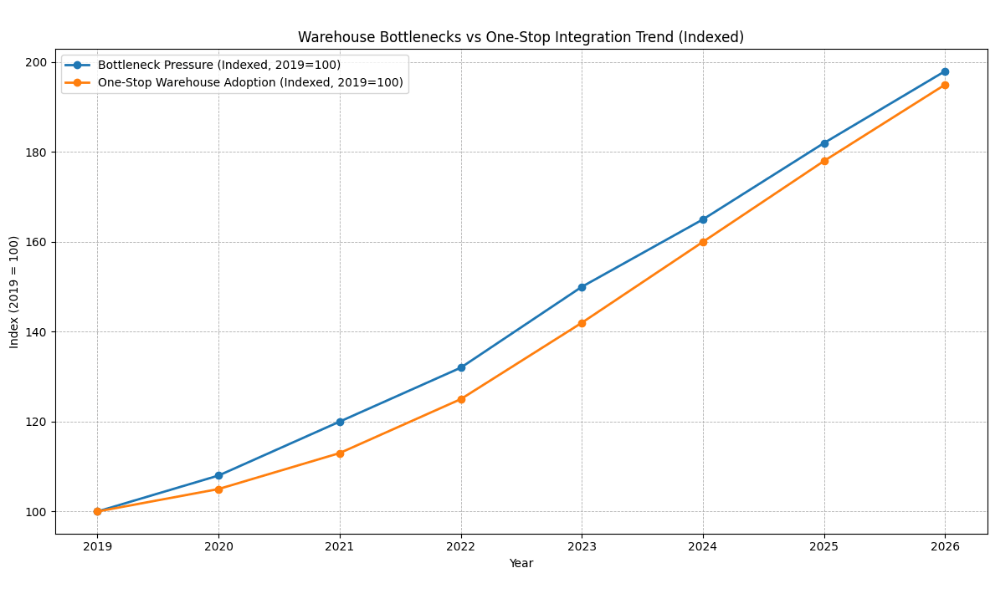

In Southeast Asia and Europe alike, the pressure is now structural. Industry research (MHI and Deloitte supply chain outlooks, plus multiple university logistics labs) repeatedly highlights the same pattern: when demand volatility rises, the “cost” of fragmentation rises faster than labour or rent. In plain English: separate tools and separate vendors don’t just add complexity—they multiply delays.

One-stop magazijn |

One-Stop Warehouse Trend |

Bottlenecks Don’t Live in One Place: Map the “Delay Chain” First

A common mistake is treating bottlenecks like a whack-a-mole game. You speed up picking, then returns explode. You add labour to packing, then inbound clogs your docks. A One-Stop Warehouse approach starts with a delay-chain map.

Step 1: Identify your bottleneck type (not just location)

Use a simple classification before you change anything:

-

Flow bottleneck: congestion at docks, cross-aisles, or pack lines.

-

Inventory bottleneck: stockouts, mis-slots, slow replenishment, poor cycle-count discipline.

-

Equipment bottleneck: not enough trucks, poor uptime, charging conflicts, maintenance delays.

-

Data bottleneck: WMS lag, unclear priorities, no real-time exception handling.

-

People bottleneck: training gaps, inconsistent SOPs, unclear ownership.

Step 2: Instrument the floor with “bottleneck KPIs”

You don’t need fancy automation to measure like a pro. Track:

-

Dock-to-stock time (receiving → putaway completed)

-

Pick path travel time per order line

-

Replenishment response time (trigger → restock completed)

-

Pack queue time and rework rate

-

Equipment availability (uptime, charging time, battery swap time)

-

Exception rate (damage, missing items, short picks)

Industry studies commonly show travel and search time dominate picking effort, which is why the biggest gains often come from layout + slotting + discipline—not from “more people.”

Step 3: Start with the most overlooked accelerator: internal movement

If your internal movement is slow, everything else becomes theatre. That’s why standardising pallettrucks and short-distance handling rules often creates immediate relief. A practical mid-warehouse education tool is this guide on pallettrucks—because many bottlenecks begin with small handling friction: inconsistent pallet profiles, poor staging etiquette, and the wrong equipment for the floor condition.

Build the One-Stop Warehouse “Backbone” (Process + Equipment + Data + Power)

One-stop doesn’t mean “one mega-vendor for everything no questions asked.” It means one integrated operating backbone where each layer supports the others.

The four-layer backbone

A One-Stop Warehouse design works best when these layers are aligned:

-

Process layer: SOPs for inbound, putaway, replenishment, picking, packing, returns.

-

Equipment layer: MHE matched to aisle widths, load types, throughput, safety rules.

-

Data layer: WMS logic that reflects reality (slotting, wave planning, exception workflows).

-

Power layer: charging strategy, energy discipline, maintenance cadence.

If any one layer is missing, your bottleneck simply migrates.

Why power planning is now a bottleneck category

Warehouses increasingly run on electric fleets. When charging is ad-hoc, you create hidden downtime—equipment queues at the wall become the new choke point.

A practical starting point is understanding forklift energy behaviour and charging discipline through heftruckbatterij planning: shift-based charge windows, battery health checks, safe ventilation, and clearly assigned ownership. Multiple industrial engineering programs have shown that predictable charging routines reduce emergency swaps, which reduces “random pauses” that destroy pick waves.

Industry-Specific Bottlenecks Need Industry-Specific Solutions

The fastest way to break a warehouse is to copy a global template into a local operation. Different industries bottleneck differently because products behave differently.

Which industries benefit most from one-stop thinking

When you compare industries, bottlenecks correlate with product traits:

-

Cold chain: temperature discipline + dock speed + packaging integrity

-

Pharma/health: traceability + compliance workflows + quarantine zones

-

Automotive parts: SKU complexity + kitting + mistake-proofing

-

E-commerce: velocity peaks + returns + wave discipline

If you want a clean overview of where integrated design wins fastest, this resource on one-stop magazijndiensten is useful because it frames the “why” by sector rather than by buzzword.

A simple “fit check” table

Use this before choosing solutions:

| Warehouse profile | Typical bottleneck | One-stop fix that works |

|---|---|---|

| High SKU, high velocity | Pick congestion + errors | Slotting rules + wave design + exception workflows |

| Low SKU, high volume | Space + replenishment timing | Dense storage + disciplined replenishment lanes |

| Temperature-sensitive | Dock delay + spoilage risk | Climate zoning + fast cross-dock + traceability |

| Regulated goods | Holds + audit friction | Controlled zones + digital checkpoints + SOP rigor |

What “Akuros-Style” One-Stop Warehouse Execution Looks Like

At a recent ESTA logistics forum, a recurring theme was that “integration beats isolated automation”—and integrated projects were praised for delivering reliability, not just speed. That’s where a One-Stop Warehouse approach becomes more than theory: it becomes a delivery method.

A practical way to describe this approach is: one system owns the whole picture, from inbound rules to fleet uptime. In that spirit, Akuros positions one-stop design around operational fit—matching equipment, layout, and service workflows so each decision reduces downstream friction.

What changes when you go one-stop

Instead of separate initiatives, you get a single operating logic:

-

Inbound appointments reflect dock capacity (not wishful thinking)

-

Putaway priorities reflect SKU velocity (not “first come, first served”)

-

Replenishment is proactive (triggered by consumption patterns)

-

Picking paths are protected from cross-traffic (less conflict, fewer pauses)

-

Fleet uptime is treated as a KPI (not “maintenance will handle it”)

How to Reduce Bottlenecks: A Practical Implementation Sequence

This is where most warehouses either win or stall: sequence.

Phase 1: Stabilise flow before you “speed up”

-

Define staging rules (where loads wait, how long, who owns them).

-

Enforce lane discipline (one-way rules, crossing minimisation, visibility).

-

Fix slotting for top velocity SKUs (reduce travel first).

-

Create a replenishment lane and protect it (no interruptions).

Phase 2: Standardise equipment + safety + energy

-

Match equipment to floor reality (turn radius, load height, aisle width).

-

Standardise handling tools for short moves vs long moves.

-

Implement charging windows, accountability, and battery health checks.

-

Train on “collision prevention behaviours” (not just forklift rules).

Phase 3: Make data operational (not decorative)

-

Move from “reporting” to “exceptions” (what must be acted on now).

-

Build a simple escalation ladder (who fixes what, how fast).

-

Tie KPIs to behaviour: dock discipline, cycle counts, replenishment speed.

For a more complete blueprint of integrated facility design, a structured magazijnoplossing approach typically frames the system as a set of interlocking modules—storage design, MHE selection, process workflow, and implementation support—rather than a single equipment purchase.

One-Stop Warehouse for E-commerce

Mini Case Snapshots: What Bottleneck Reduction Looks Like in Practice

Below are realistic patterns observed across multi-site operations. These are written as “field patterns” rather than confidential client disclosures, but they mirror the logic used in integrated projects.

Case 1: E-commerce cutoffs (Jakarta-style peak volatility)

Problem: pick waves collapsed due to replenishment delays.

Fix: protected replenishment lane + slotting by velocity bands + wave timing rules.

Result pattern: fewer “urgent replenishments,” smoother pack queues, fewer late carts.

Case 2: Cold chain (Bangkok-style dock pressure)

Problem: inbound congestion created temperature risk and pack-line chaos.

Fix: dock appointment logic + fast cross-dock lanes + stricter staging discipline.

Result pattern: less dwell time, fewer exceptions, cleaner traceability.

Case 3: Multi-SKU industrial parts (Ho Chi Minh kitting complexity)

Problem: kitting errors caused rework and late dispatch.

Fix: process checkpoints + mistake-proofing + clearer exception workflow.

Result pattern: fewer rework loops, higher first-pass accuracy.

If you want to translate your bottleneck map into a scoped plan, the fastest path is to contact met ons opnemen with your SKU profile, peak patterns, dock constraints, and fleet setup—because bottlenecks are context-dependent, and a good one-stop plan starts with your operating promise (cutoff targets, compliance, service levels).

And if you need to align internal stakeholders first (procurement, ops, finance), referencing over helps clarify the “system owner” concept—who is accountable for the full workflow, not just a single purchase.

FAQ

1) What is a One-Stop Warehouse approach?

It’s an integrated operating model where process design, material handling, data workflows, and energy planning are built as one coordinated system—so bottlenecks don’t simply shift from one department to another.

2) What is the quickest bottleneck to fix first?

Usually internal movement: slotting, staging discipline, and replenishment timing. These changes reduce travel and waiting, which often unlocks capacity without adding headcount.

3) Do I need automation to reduce bottlenecks?

Not always. Many facilities gain more by stabilising flow, standardising SOPs, and improving equipment uptime before automating a proven constraint.

4) Why do forklift charging routines matter so much?

Because unpredictable charging creates hidden downtime and disrupts pick waves. A planned energy routine turns fleet availability into a controllable KPI instead of an operational surprise.

5) How do I know if one-stop is worth it for my operation?

If you have frequent cutoff misses, recurring congestion at the same time daily, high exception rates, or “multi-vendor blame loops,” you’re likely paying the fragmentation tax—and one-stop integration can reduce it.

The Bottleneck Isn’t Dispatch—It’s Fragmentation

If your team keeps asking why dispatch misses cutoffs, the honest answer is usually that dispatch is only where the problem becomes visible. A One-Stop Magazijn approach reduces bottlenecks by eliminating the coordination gaps that create delay chains: mismatched handling tools, unmanaged charging behaviour, weak staging rules, and data that reports problems instead of preventing them.

The most effective warehouses don’t chase isolated speed. They build reliability—a system where inbound timing, storage logic, replenishment discipline, and fleet uptime all pull in the same direction. That’s exactly why recent ESTA discussions increasingly praise integrated, system-owned implementations: the win isn’t just faster output; it’s fewer surprises.

So the fix is not “work harder at dispatch.” The fix is to make the warehouse behave like one business, one rhythm, one accountable system. When that happens, bottlenecks stop migrating—and cutoffs stop being a weekly drama.