Exploring Drive-in Racking Systems

Drive-in Rackings are a type of vehicle access racking system designed to eliminate unnecessary aisles, enabling forklifts to drive directly into the racking structure to deposit or retrieve pallets. This system is particularly ideal for storing large volumes of the same SKU. Unlike selective racks, which allow access to every pallet independently, Drive-in Rackings operate on a LIFO (Last In, First Out) basis, meaning the last pallet stored is the first one retrieved. This design greatly enhances storage efficiency, especially for non-perishable or slow-moving goods.

How Drive-in Rackings Enhance Storage Density

One of the most significant advantages of Drive-in Rackings is their ability to increase storage density by reducing the number of access aisles. In traditional racking systems, each pallet position requires its own aisle. However, Drive-in Rackings eliminate these aisles by allowing forklifts to drive into the rack structure itself. This dramatically increases the number of pallets that can be stored per cubic meter, offering a smart solution for companies facing space maximization challenges in already packed warehouses.

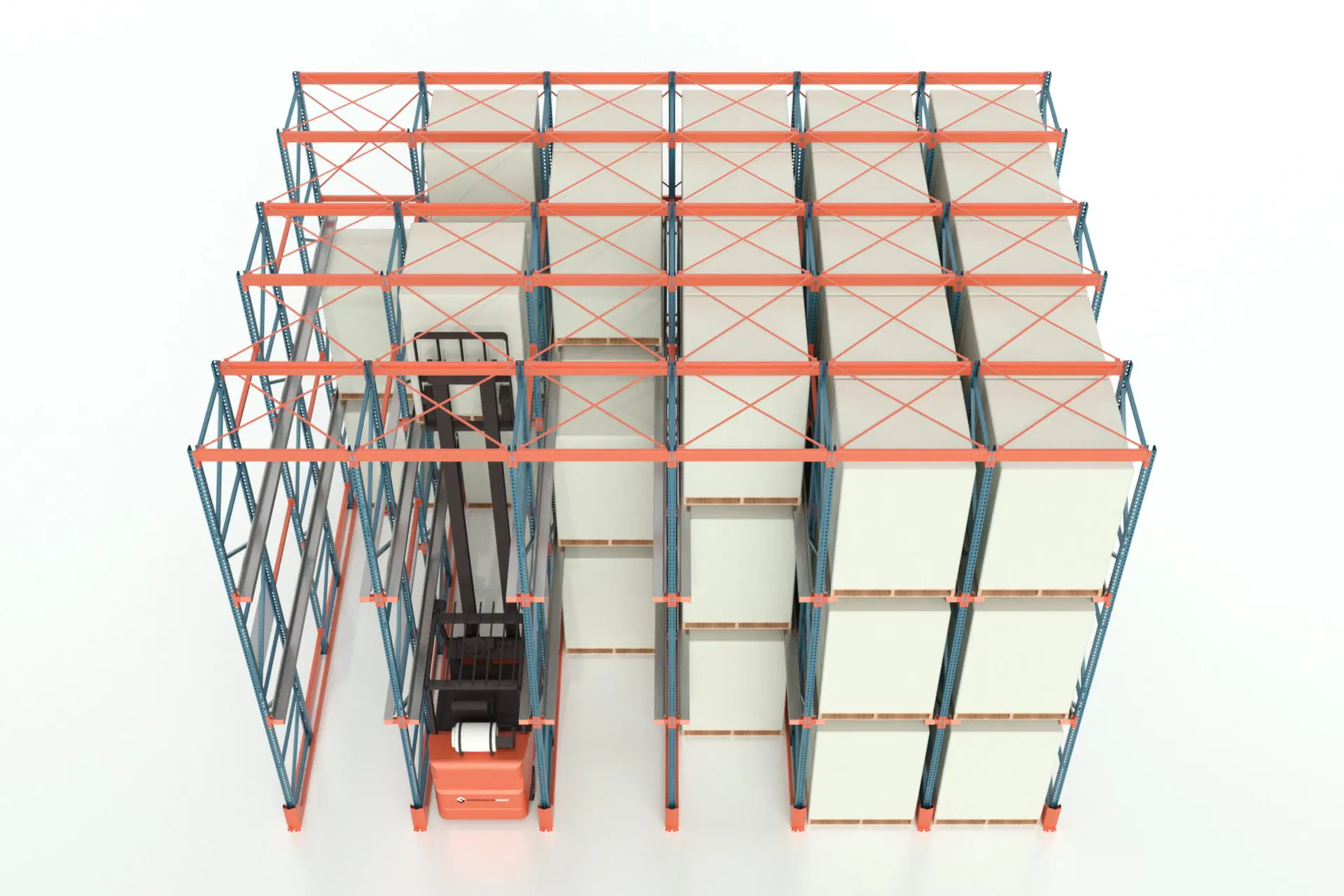

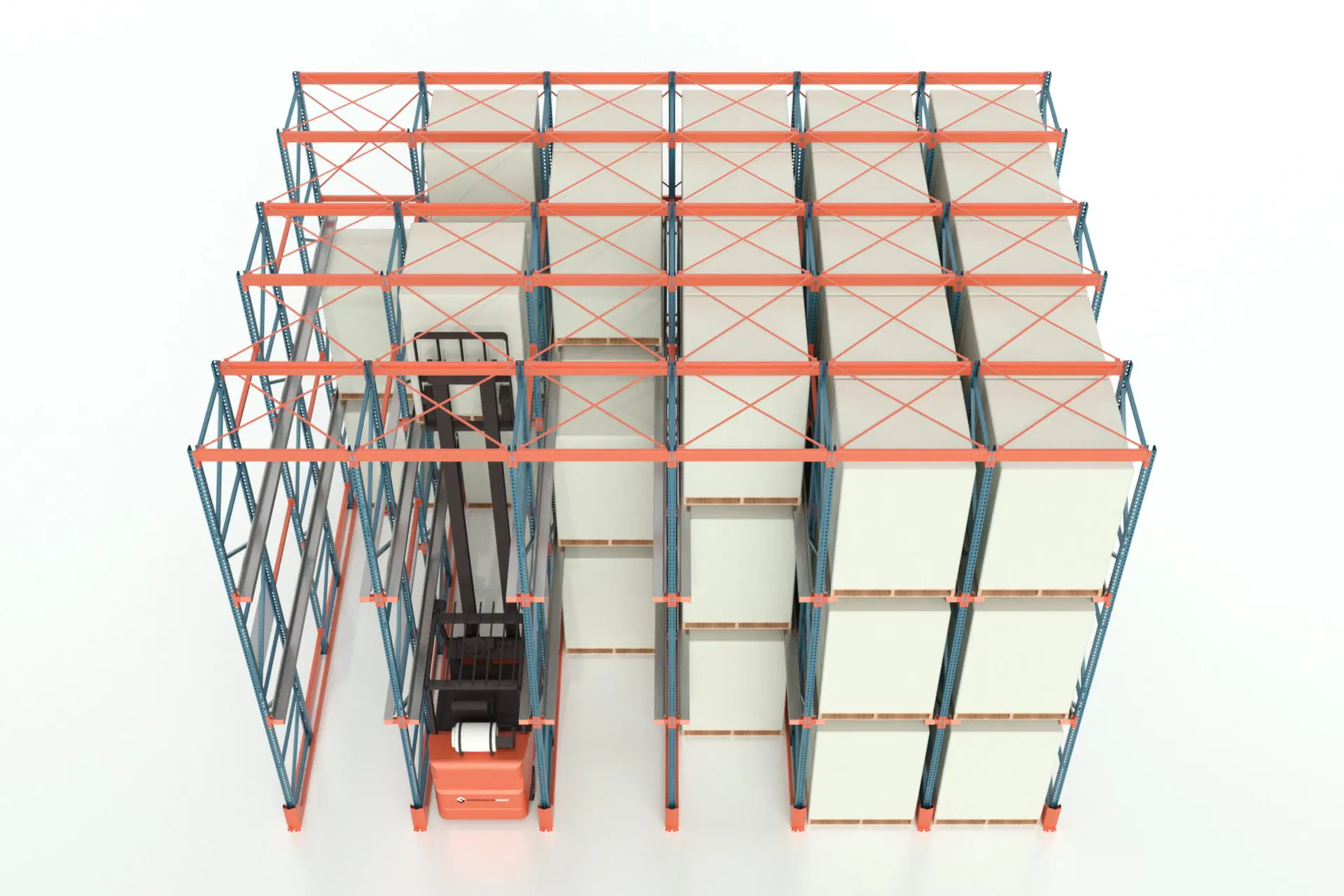

Drive-in Rackings

Benefits of Drive-in Rackings for Uniform Products

When your warehouse deals primarily with uniform product storage, Drive-in Rackings shine. Their design is best suited for storing large quantities of the same product type. Industries such as dairy, beverage, and frozen foods benefit tremendously from this setup. Since the system operates on a LIFO principle, it’s especially useful in environments where stock rotation is less critical, but inventory management and bulk storage are key priorities.

Design and Structure of Drive-in Racking Systems

The architecture of Drive-in Rackings is tailored for load handling efficiency and safety. Constructed with robust upright frames, horizontal load rails, and support arms, the system creates multiple storage lanes deep enough to hold several pallets back-to-back. The racking is engineered to withstand the pressure and weight of forklifts entering and exiting the structure, and is often anchored to the floor for added stability. Proper rack design and safety considerations are essential to prevent structural damage and ensure operator safety.

Vehicle Compatibility and Operational Efficiency

Not all forklifts are suitable for Drive-in Rackings. Operators typically use narrow-aisle forklifts or counterbalance forklifts capable of maneuvering inside the racking lanes. These machines need excellent control and visibility due to the limited space within the racking structure. With skilled drivers and compatible equipment, vehicle access racking can become a highly efficient system that significantly boosts operational efficiency, reduces loading time, and ensures smoother material flow within the warehouse.

Maximizing Warehouse Space Utilization

With real estate prices climbing and expansion costs soaring, maximizing existing warehouse space optimization has never been more important. Drive-in Rackings provide a vertical and horizontal advantage by optimizing both floor space and cubic storage. When properly planned, businesses can increase their storage capacity by up to 75% compared to conventional racking systems. This allows warehouses to store more products without relocating or undertaking expensive construction projects.

Safety Protocols for Drive-in Racking Operations

Safety is paramount in any warehouse setup, especially one involving Drive-in Rackings. Since forklifts operate within the structure, the risk of collision with racking frames is higher. Safety measures such as rack protectors, guide rails, adequate signage, and routine inspections are essential. Operator training plays a critical role in preventing accidents and maintaining the integrity of the racking system. Compliance with local safety regulations ensures a secure environment and reduces downtime caused by preventable mishaps.

Cost Analysis and ROI of Implementing Drive-in Rackings

While the initial investment in Drive-in Rackings may be higher than selective racking, the long-term benefits far outweigh the cost. Companies often see a quick return on investment through increased storage efficiency, reduced warehouse footprint, and lowered utility costs (especially in cold storage). Fewer aisles mean fewer lighting fixtures and reduced energy usage, which can significantly cut operational expenses. When evaluating cost vs. benefit, the potential ROI makes Drive-in Rackings a smart choice for warehouses dealing with space constraints and bulk storage.

Future Trends and Innovations in Drive-in Racking Technology

As automation and smart warehousing gain traction, Drive-in Rackings are evolving to meet modern demands. Integration with automated guided vehicles (AGVs) and warehouse management systems (WMS) is becoming more common. Sensors and tracking systems can now be embedded to monitor rack loads, inventory levels, and structural integrity in real time. These advancements promise to make Drive-in Rackings even more efficient, safe, and compatible with the fast-paced logistics environment of the future.

Enhancing Inventory Management with Drive-in Rackings

Although Drive-in Rackings are often associated with bulk and simple inventory management, they can also support advanced inventory tracking through barcoding and WMS integration. Modern racking layouts are being designed with space for RFID readers and automated scanning to track pallet locations and retrieval times. This hybrid model of manual storage with digital oversight creates a balance between high-density storage and intelligent warehouse operations.

Drive-in Rackings supplier

In today’s competitive logistics landscape, optimizing warehouse capacity is not just a luxury—it’s a necessity. Drive-in Rackings offer a robust solution for businesses seeking to enhance storage efficiency, manage uniform product storage, and maximize space utilization. By reducing aisle space and allowing forklifts to drive directly into the structure, these systems effectively double storage capacity within the same footprint.

From a cost-saving perspective to future-proofing your operations with smart integrations, Drive-in Rackings continue to evolve and adapt to the growing needs of modern supply chains. Their benefits extend beyond simple space savings—they support better inventory management, improve vehicle access racking, and contribute to overall warehouse space optimization.

If your warehouse is struggling with limited space and you’re storing high volumes of the same products, Drive-in Rackings could be the solution that transforms your operation. With the right planning, training, and system design, your storage challenges can turn into strategic advantages, setting you apart in a competitive marketplace.For example: “Want to learn more about Drive-in Rackings? Contact us now to get a quote!”