Real-World Challenges: Why Middle Eastern Warehouses Need Heavy Duty Racking Systems

Fatima (Logistics Manager, Dubai Free Zone):

“Our storage is maxed out. We can’t expand the footprint, and every extra pallet feels like a safety risk.”

Omar (Warehouse Engineer, Riyadh):

“That’s because traditional racking systems were never designed for this kind of throughput. They buckle under mixed loads. What we need are heavy-duty racks with proper seismic and thermal resistance.”

David (Supply Chain Solutions Buyer, Akuros):

“At Akuros, we’ve helped Middle Eastern logistics hubs transition to Heavy Duty Racking Systems. When you integrate racking, safety design, and smart inventory planning under one warehouse solution, you gain durability, compliance, and long-term ROI—all while supporting sustainable growth.”

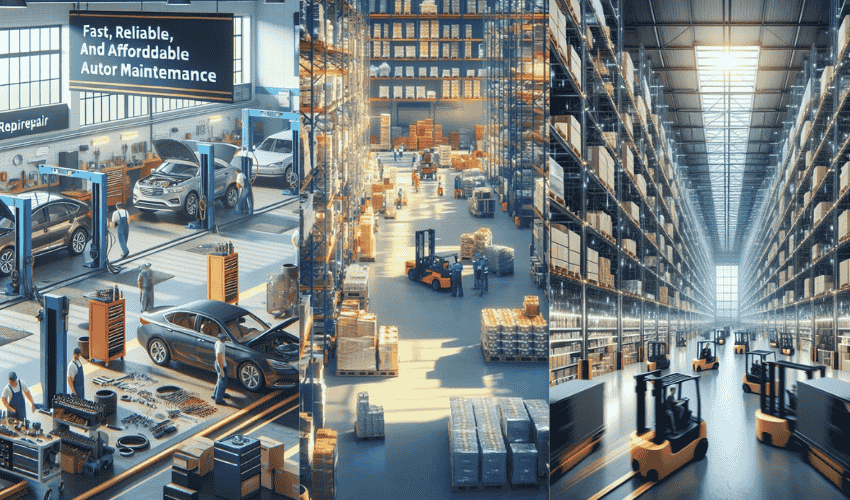

One-Stop Warehouse Solutions- Heavy Duty Racking Systems

The Middle East Logistics Boom: Why It Matters

Over the past decade, the Middle East has become a logistics hub linking Asia, Europe, and Africa. According to PwC’s Middle East Logistics Outlook 2025, the GCC region’s warehousing capacity has grown by over 40% since 2019. But this growth brings challenges:

-

Limited industrial land in urban free zones.

-

Rising temperature impacts on metal fatigue and equipment.

-

ESG and EPR compliance pressures from global buyers.

These constraints make Heavy Duty Racking Systems essential for long-term resilience and sustainable growth.

What Defines a Heavy Duty Racking System?

A Heavy Duty Racking System is designed to handle loads exceeding 3,000 kg per level, maintain stability under seismic or thermal stress, and integrate with automation such as pallet shuttles or AS/RS systems.

Key Components:

-

Cold-Rolled Steel Beams: For high strength-to-weight performance.

-

Reinforced Uprights: Designed for seismic and temperature resilience.

-

Anti-Corrosion Coating: Ideal for coastal climates like the UAE and Oman.

-

Modular Adjustability: Supports palletized, bulk, or cartonized goods.

Material Selection and Engineering Excellence

1. Premium Materials

Heavy duty systems use industrial-grade steel conforming to EN 15512 and ASTM A36 standards.

-

Powder coating prevents oxidation even in 50°C+ temperatures.

-

Bolted joints allow flexible expansion without welding.

-

Epoxy coating ensures anti-corrosion performance in humid ports.

2. Advanced Manufacturing Process

-

Robotic welding for precision and uniform strength.

-

CNC drilling and laser cutting for perfect hole alignment.

-

Load testing and static simulation under ISO 9001 quality management.

3. Why It Outperforms Conventional Racking

| Feature | Heavy Duty Racking | Standard Racking |

|---|---|---|

| Load Capacity | 3,000–6,000 kg/level | 800–1,500 kg/level |

| Safety | Seismic & thermal certified | Limited tolerance |

| Longevity | 15–20 years | 5–8 years |

| Maintenance | Minimal, modular | Frequent repair |

| ESG Impact | Recyclable steel | Higher material waste |

Expert Insights & Industry Data

Dr. Lina Hassan, Middle East Supply Chain Journal (2024):

“Integrated racking systems are becoming the backbone of sustainability in Gulf logistics. They optimize cubic storage, lower carbon emissions, and improve energy use efficiency.”

Scientific Data:

-

McKinsey (2024): Centralized warehousing improves space utilization by 25–35%.

-

MIT Logistics Lab (2023): Automated racking systems reduce workplace accidents by 40%.

-

Deloitte (2024): Companies upgrading to heavy-duty racking cut maintenance costs by 30% and downtime by 18%.

Real-World Applications in the Middle East

Case 1 – Dubai Free Zone: Compact Expansion Without Construction

A major e-commerce distributor replaced outdated shelving with heavy duty racking systems. Result:

-

40% more storage capacity in the same footprint.

-

Improved safety audit scores from 72% → 95%.

-

No additional construction costs.

Case 2 – Saudi Arabia Industrial Warehouse

A machinery supplier faced temperature-related metal fatigue. After adopting heavy duty racks with heat-resistant coatings:

-

Downtime dropped by 25%.

-

Rack lifespan extended by 7 years.

Case 3 – Oman Logistics Hub (ESG Integration)

A shipping terminal adopted a one-stop warehouse solution integrating heavy-duty racking, automation, and solar-powered lighting:

-

20% lower electricity consumption.

-

Full EPR documentation for European buyers.

Heavy Duty Racking Systems

Customer Feedback

Ahmed, Operations Director (UAE):

“Our previous racks couldn’t handle mixed loads. Since switching to heavy duty systems, we haven’t had a single collapse incident.”

Rana, Warehouse Supervisor (Saudi Arabia):

“The one-stop warehouse solution simplified everything—layout, safety, and expansion. The ROI showed up in under a year.”

Hassan, Import Manager (Kuwait):

“Integrating ESG reporting through warehouse design made our audits smoother and our clients happier.”

Expert Interpretation

“Warehouse optimization is not just about stacking higher; it’s about building smarter. The Middle East’s logistics future depends on sustainability, automation, and racking systems engineered for resilience.”

— Prof. Elena Rossi, Journal of Global Logistics, 2024

Frequently Asked Questions

1. What makes a Heavy Duty Racking System different?

It handles higher loads, resists corrosion and seismic stress, and integrates automation for modern logistics.

2. Why are these systems crucial in the Middle East?

They address space limits, heat resilience, and sustainability targets set by regional logistics regulators.

3. Are heavy duty racking systems compatible with automation?

Yes, they integrate easily with AS/RS, pallet shuttles, and smart picking robots.

4. How do they support ESG compliance?

By using recyclable steel, energy-efficient design, and durability that reduces material waste.

5. Can small warehouses benefit too?

Absolutely. Modular systems allow small operations to scale up without major capital investments.

One-stop warehouse for various industries

References

-

Deloitte (2024) – Global Supply Chain Resilience Report. Deloitte Insights.

-

McKinsey & Company (2024) – Next-Generation Warehousing: Trends in Centralized Logistics.

-

PwC Middle East (2024) – Warehousing Outlook in the GCC: From Expansion to Efficiency.

-

MIT Center for Transportation & Logistics (2023) – Impact of Racking Systems on Warehouse Lifecycle.

-

Hassan, L. (2024) – Sustainable Infrastructure in Gulf Supply Chains. Middle East Supply Chain Journal.

-

World Economic Forum (2024) – Global Trade and Supply Chain Future Outlook.

-

El-Sharif, A. (2023) – ESG Adoption in the Middle East Logistics Sector. Arabian Business Review.

-

ASTM International (2023) – Structural Steel Standards for Warehouse Applications.

-

European Committee for Standardization (CEN, 2023) – EN 15512: Steel Static Storage Systems.

-

Rossi, E. (2024) – Safety and Sustainability Integration in Modern Warehousing. Journal of Global Logistics.

Heavy Duty Racking Systems are redefining Middle Eastern warehousing.

They deliver space efficiency, operational safety, and ESG compliance—turning warehouses into sustainable, intelligent ecosystems.

As Gulf economies continue to diversify, logistics hubs that adopt these integrated systems will gain a decisive competitive edge—growing not by building more space, but by optimizing what they already have.

In the Middle East, where climate conditions and space limitations challenge traditional designs, one-stop warehouse solutions offer a holistic path forward.Research by McKinsey and MIT confirms measurable ROI—reduced accidents, increased capacity, and compliance readiness.

These racking systems bridge industrial engineering and environmental responsibility, supporting regional ESG frameworks and global trade competitiveness.For buyers, adopting integrated solutions means lower lifecycle costs and higher operational reliability. For governments, it means greener infrastructure aligned with Vision 2030 and the UAE’s Net Zero goals.

Simply put: heavy duty racking systems are the scaffolding of sustainable growth in the Middle East’s logistics transformation.