Contents

Understanding Double Depth Racking Systems

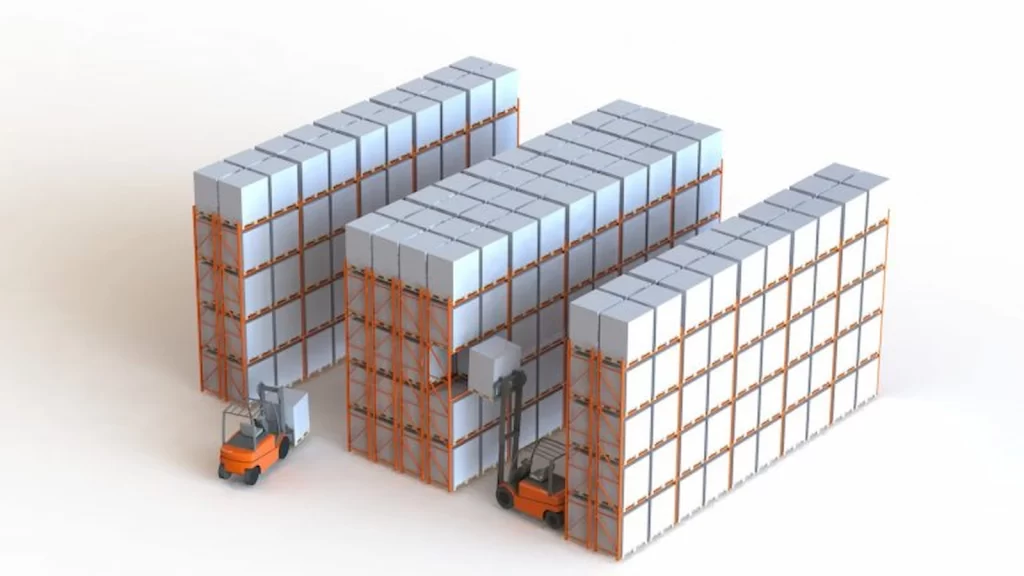

Double Depth Racking is a high-density storage solution designed to enhance warehouse efficiency by storing two pallets deep on each side of the aisle. This system offers a smart compromise between selective and deep lane storage, combining the benefits of high storage density with relatively good load accessibility.

In contrast to conventional selective racking, where each pallet is directly accessible, double-deep storage requires the use of specialized forklifts with extendable forks to access rear pallets. This system is best suited for businesses managing large volumes of the same SKU, as it minimizes aisle space while maximizing storage capacity. In fast-moving industries or high-throughput distribution centers, Double Depth Racking plays a critical role in space-saving storage organization.

How Double Depth Racking Doubles Storage Capacity

The most notable advantage of Double Depth Racking is its ability to nearly double pallet storage capacity within the same floor area. By placing one pallet behind another, the number of aisles needed is reduced, freeing up more space for vertical or horizontal storage expansion.

This type of deep storage racking is particularly valuable in urban warehouses or facilities where real estate costs are high. By using fewer aisles, businesses can either increase the number of pallets stored or reduce the required square footage for new warehouse designs.

While direct access is limited to the front pallet, the system achieves an optimal balance between selectivity and space utilization, making it an ideal choice for slow-to-medium turnover products stored in bulk.

Double Depth Racking

Key Components of Double Depth Racking

Double Depth Racking systems are constructed using standard industrial racking components with reinforced frames and beams to support the additional load depth. Uprights, double-entry frames, and horizontal bracing are designed to ensure structural stability while accommodating dual-pallet configurations.

Additionally, guide rails and pallet support bars may be included to enhance rack safety and reduce pallet deflection. The system also requires specific handling equipment—typically reach trucks or forklift operations with telescopic forks—to safely access the second pallet position.

All materials used are designed for cost-effective storage, with high load-bearing capacity and long-lasting finishes that resist corrosion and mechanical stress.

Applications in Warehouse Management

Double Depth Racking is widely used in industries where bulk storage of similar products is common. Sectors such as food and beverage, automotive parts, consumer goods, and cold storage facilities greatly benefit from this efficient layout.

In inventory management, this system supports stock rotation strategies like FIFO (First In, First Out) and LIFO (Last In, First Out), depending on configuration. Its use is often optimized in environments with batch picking and seasonal inventory fluctuations.

Additionally, the system’s ability to improve storage density without compromising workflow makes it highly suitable for businesses seeking to scale operations within existing infrastructure.

Installation and Configuration Guidelines

Proper installation of Double Depth Racking requires careful planning and assessment of available floor space, storage capacity requirements, and handling equipment capabilities. The system should be configured with precise aisle spacing to accommodate the reach and maneuverability of telescopic forklifts.

Installation involves anchoring frames to the warehouse floor, assembling upright frames, and installing double beams to hold paired pallets. It’s critical to align all components accurately to ensure safe and efficient forklift operations.

Designers must consider ceiling height, load limits, and the turning radius of equipment to avoid operational constraints. Moreover, safety signage and protective barriers should be installed to mitigate damage from equipment collisions.

Load Handling and Retrieval Techniques

Operating a Double Depth Racking system involves specific techniques for effective load handling and retrieval. Since the rear pallet can only be accessed once the front pallet is removed, careful planning of storage location and turnover is essential.

Operators typically use reach trucks or articulated forklifts with specialized fork extensions. Training is crucial to ensure that operators handle pallets accurately without damaging the racks or goods, especially at higher beam levels.

Retrieval must follow proper sequences to minimize travel time and maximize throughput. To aid in this process, some facilities integrate barcoding or warehouse management software that maps double-deep storage locations and improves retrieval efficiency.

Double Deep Racking supplier

Safety Considerations and Best Practices

With increased storage depth comes heightened emphasis on rack safety. Facilities using Double Depth Racking must enforce best practices to prevent accidents and damage. Regular inspections of beams, frames, and connections are critical to maintaining structural integrity.

Load distribution must always remain within system specifications. Overloading can lead to rack collapse or pallet failure, especially for the rear position. Operators should be trained to avoid sudden lifts or impacts when extending forks into deep storage racking.

Safety accessories such as upright protectors, beam locks, and pallet backstops can enhance system resilience. A proactive maintenance and safety protocol reduces risk and ensures the long-term performance of the industrial racking systems.

Maintenance Requirements for Long-Term Use

To ensure the longevity and functionality of Double Depth Racking, periodic maintenance is required. This includes checking for rust, bent beams, loosening bolts, and wear from forklifts. Visual inspections should be performed monthly, with full structural assessments conducted annually.

Forklifts used in double-deep storage systems must also be maintained, especially the telescopic mechanisms, to guarantee smooth and safe operation. Routine maintenance schedules aligned with manufacturer recommendations will prevent operational disruptions and reduce total ownership cost.

Clean and well-maintained racking also minimizes damage to stored goods and improves employee morale by promoting a safe and orderly work environment.

Cost-Benefit Analysis of Double Depth Racking

Although Double Depth Racking systems may involve higher upfront costs due to equipment and forklift requirements, the long-term benefits far outweigh the initial investment. Businesses achieve higher storage capacity, optimized space utilization, and reduced expansion costs.

The system also reduces labor time and enhances picking efficiency when paired with proper inventory planning. Improved storage organization minimizes product damage, accelerates retrieval times, and supports scalable growth.

When comparing cost per pallet position to traditional selective racking, Double Depth Racking often delivers superior ROI, especially for medium- to high-volume storage environments.

High quality Double-deep racking

Double Depth Racking stands out as one of the most effective solutions for enhancing warehouse efficiency and maximizing available space. Its ability to double pallet storage without a corresponding increase in warehouse footprint makes it ideal for businesses managing high volumes of uniform SKUs.

From optimized space utilization and increased storage density, to streamlined forklift operations and long-term cost savings, this system supports every aspect of modern inventory management. It aligns well with the evolving needs of industries that demand both efficiency and scalability in their storage strategies.

By investing in proper installation, training, and maintenance, businesses can ensure safe and reliable performance of Double Depth Racking for years to come. As warehouse technologies advance, we can also expect new innovations in deep storage racking design—offering even greater flexibility, automation compatibility, and sustainability in future storage infrastructures.For example: “Want to learn more about Double Depth Racking? Contact us now to get a quote!”

Previous News

The Ultimate Guide to Ordinary Beam RacksNext News

Struggling with Warehouse Space? Drive-in Racki...Share: