In today’s fast-paced and space-constrained warehousing environments, businesses are constantly seeking smarter storage methods that optimize both capacity and efficiency. Double Deep Racking Solutions have emerged as a go-to strategy for industries needing a balance between density and accessibility.

By doubling up the depth of standard selective pallet racks, this configuration allows up to 40% more storage capacity in the same footprint, making it an ideal choice for warehouses where every square meter counts.

Double Deep Racking Solutions

How Double Deep Racking Maximizes Storage Capacity and Space Efficiency

Double Deep Racking Solutions consist of two rows of pallets stored back-to-back, accessible via a deep-reach forklift. Unlike single selective racks that offer one pallet deep storage per rack face, double deep racking provides two pallet positions in depth. This arrangement reduces aisle space requirements and increases storage density significantly.

However, the tradeoff is that only the front pallet is immediately accessible, with the rear pallet following a First-In, Last-Out (FILO) inventory system. This setup works best in operations where product SKUs are uniform or where turnover is predictable.

Advantages of Double Deep Racking Systems

1. Increased Storage Density

By storing pallets two-deep, businesses can increase pallet positions per square meter by 20% to 40% compared to standard selective racking. This makes it a powerful solution for maximizing vertical and horizontal warehouse space.

2. Ideal for Bulk and Like-Product Storage

Facilities that store a high volume of the same or similar products benefit significantly from Double Deep Racking Solutions. The ability to group like-items in a denser format ensures operational flow while reducing travel time for pickers.

3. 50% Instant Accessibility

While 100% immediate accessibility isn’t possible with this system, 50% of pallet positions are instantly accessible, striking a balance between selectivity and density. It’s a favorable compromise for many warehouse applications.

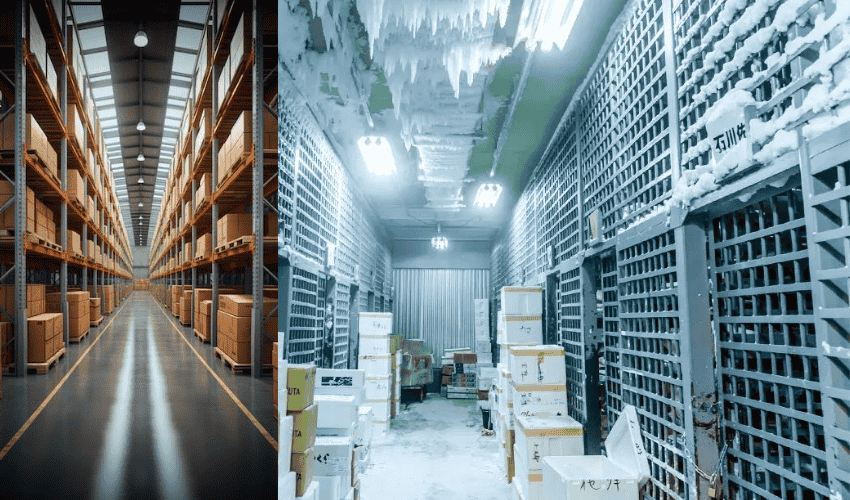

4. Adaptable to Cold and Freezer Storage

In cold chain logistics, space is at a premium due to the high costs of cooling. Double Deep Racking Solutions are commonly deployed in freezer and refrigeration warehouses where storage density helps offset energy expenses.

Key Design Considerations

When planning and installing Double Deep Racking Solutions, certain engineering and operational elements must be considered to ensure safety and efficiency:

| Factor | Description |

|---|---|

| Beam and Upright Thickness | Must be specified based on load requirements and height. |

| Connection Design | Bolted or welded frame designs influence rigidity and future adjustments. |

| Seismic Compliance | For earthquake-prone regions, the design must adhere to seismic codes. |

| Weight Distribution and Point Loads | Must be evenly distributed to prevent rack failure. |

| Engineering Support | Structural calculations and customization ensure reliability and load-bearing accuracy. |

Partnering with a supplier that provides certified structural calculations and tailored engineering services ensures long-term performance.

Operational Applications of Double Deep Racking

1. Retail Distribution Centers

Major retailers and wholesalers who manage consistent SKU volumes often use Double Deep Racking Solutions to reduce aisle congestion and increase storage throughput.

2. Cold Storage Facilities

The high energy cost of refrigeration means space efficiency becomes vital. Cold storage warehouses routinely opt for double deep systems to maximize pallet counts in controlled environments.

3. Automotive and Spare Parts Warehouses

Warehouses managing inventory in batches or kits benefit from the grouped storage format. FILO systems also align with the long shelf life of many automotive components.

4. Food and Beverage Industry

Bulk products with fast turnover, such as bottled drinks or canned goods, are perfect candidates. These items don’t require high selectivity and are replenished frequently.

Equipment Requirements

To efficiently operate Double Deep Racking Solutions, businesses must invest in or lease deep-reach forklifts. These forklifts feature telescopic forks designed to reach the second pallet without destabilizing the load.

| Equipment Type | Key Feature |

|---|---|

| Deep-Reach Forklift | Extended forks to access rear pallets |

| Narrow Aisle Trucks | Helps maintain tighter aisle spacing |

| Wire Guidance Systems | For high-density warehouse navigation |

Training forklift operators is essential, as accessing the second pallet requires skill, accuracy, and awareness of load balance.

Safety and Maintenance

Safety is paramount in high-density racking systems. Here are a few guidelines to maintain safety in Double Deep Racking Solutions:

-

Conduct regular rack inspections for deformation or impact damage.

-

Enforce weight limits as per engineering recommendations.

-

Implement safety accessories like pallet backstops, frame guards, and rack protectors.

-

Train forklift operators in safe deep-reach techniques.

-

Schedule periodic audits by certified racking inspectors.

Investing in rack protection systems may increase upfront costs, but drastically reduces the chance of structural failure.

High-quality Double Deep Racking Solutions

Cost-Efficiency and ROI

While the initial investment in Double Deep Racking Solutions may be higher than selective racking, the long-term ROI is compelling. Here’s how:

-

Reduced real estate needs by maximizing cubic space.

-

Lower HVAC costs in temperature-controlled environments.

-

Faster ROI when used in high-volume inventory scenarios.

-

Longer operational lifespan due to robust design.

When engineered correctly and paired with the right material handling equipment, double deep racking can outperform conventional systems in total cost of ownership.

Is Double Deep Racking Right for You?

Ask the following questions to determine if Double Deep Racking Solutions are suitable for your facility:

-

Do you manage a high volume of identical or similar SKUs?

-

Is warehouse space limited and costly to expand?

-

Can you operate effectively with 50% direct pallet accessibility?

-

Do you have (or plan to invest in) compatible forklifts?

-

Are you looking to optimize cold storage or bulk areas?

If the answer is yes to most of these, then double deep racking can significantly enhance your warehousing strategy.

Case Studies and Real-World Impact

A leading beverage distributor in Southeast Asia upgraded from selective racking to Double Deep Racking Solutions across its 5,000-square-meter warehouse. The result was a 35% increase in storage capacity and a 25% reduction in forklift travel time. Similarly, a cold storage facility in Europe reported energy savings of up to 18% per month due to a more efficient use of refrigerated space.

Refrigerated warehouse one-stop warehouse

Double Deep Racking Solutions offer a smart middle ground between high-density storage and moderate accessibility. For businesses dealing with high-turnover or bulk products, this system provides a significant advantage in warehouse space utilization—up to 40% increase in storage capacity in the same footprint.

Whether you’re managing a cold storage unit, retail distribution center, or industrial warehouse, embracing double deep racking could streamline operations, reduce costs, and improve long-term scalability. With the right engineering support and handling equipment, this solution delivers efficiency without sacrificing control.

Previous News

How to Choose the Right Heavy Duty Pallet Rack ...Next News

Top 5 Benefits of Using a Drive-in Racking Syst...Share: