Contents

- 1 Forklift Attachments Enhance Material Handling Efficiency

- 1.1 Akuros Forklift Accessories Are Trusted by Global Businesses

- 1.1.1 Quality and Innovation Are Central to Forklift Accessories

- 1.1.1.1 Fork Positioners Streamline Loading and Unloading Processes

- 1.1.1.2 Side Shifters Increase Operational Flexibility in Tight Spaces

- 1.1.1.3 Multi-function Attachments Provide Versatility for Various Tasks

- 1.1.1.4 Selecting the Right Forklift Accessories for Your Needs

- 1.1.1.5 Installation and Operation Require Proper Planning

- 1.1.1.6 Maintenance and Safety Tips for Long-Term Performance

- 1.1.1 Quality and Innovation Are Central to Forklift Accessories

- 1.1 Akuros Forklift Accessories Are Trusted by Global Businesses

Forklift Attachments Enhance Material Handling Efficiency

In the fast-paced world of logistics and warehousing, efficiency is everything. Forklift Accessories are essential tools that help businesses move, lift, and handle materials more safely and productively. Among the most popular and widely used are forklift attachments, which serve as enhancements to the basic forklift structure, enabling it to perform specialized tasks with precision. Whether it’s lifting drums, rotating loads, or positioning forks, forklift attachments directly contribute to faster load cycles, improved material handling, and greater workplace safety.

By expanding the functionality of standard forklifts, these accessories allow businesses to optimize every inch of their warehouse efficiency. They reduce the need for manual labor, eliminate the use of multiple machines for different tasks, and speed up order fulfillment in both indoor and outdoor environments.

Akuros Forklift Accessories Are Trusted by Global Businesses

Akuros has earned a global reputation for its premium-quality forklift accessories. With a product range tailored for a wide array of industrial applications, Akuros focuses on durability, innovation, and ergonomic design. Their forklift attachments are trusted by logistics companies, manufacturers, and distribution centers around the world.

Akuros understands the challenges of modern material handling—limited space, time pressure, and heavy workloads—and has designed its accessories to meet these exact needs. Whether it’s a side shifter, a fork positioner, or a rotator, every accessory is engineered for high performance under the most demanding conditions. Businesses that use Akuros equipment report improvements in productivity, reduced downtime, and enhanced operational flexibility.

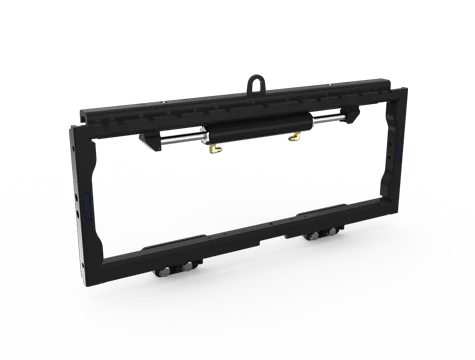

Side Shifters

Quality and Innovation Are Central to Forklift Accessories

The effectiveness of forklift accessories depends heavily on two key elements: quality and innovation. High-quality accessories are built to withstand wear, resist damage under load stress, and perform reliably through thousands of hours of operation. Innovation, meanwhile, ensures that accessories keep pace with the evolving demands of warehouse automation, smart logistics, and safety regulations.

In today’s market, innovation includes integrated sensors for load control, hydraulically powered attachments for speed and precision, and modular designs that allow one forklift to perform multiple functions. These advancements in forklift attachments enable more precise load handling, improved operator control, and easier integration with warehouse management systems.

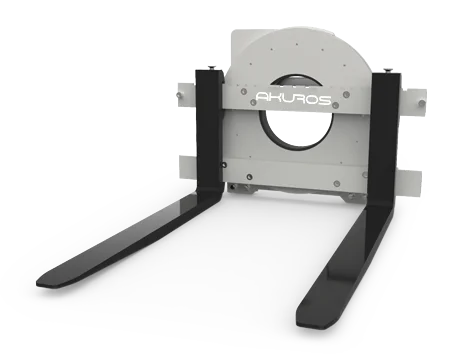

Fork Positioners Streamline Loading and Unloading Processes

Fork positioners are an indispensable tool in high-volume operations where pallet sizes or load widths frequently vary. These forklift accessories allow the forks to be hydraulically adjusted without the driver leaving the cab, significantly reducing time and labor.

By aligning forks automatically, fork positioners enhance safety and reduce the risk of damaging goods or pallets. In warehouses with diverse product lines, this functionality proves invaluable, allowing for seamless material handling transitions between products of varying dimensions.

Using fork positioners improves accuracy in pallet engagement and helps extend the life of both pallets and forks by ensuring proper fork placement every time. They are especially beneficial in operations involving fragile or uneven loads.

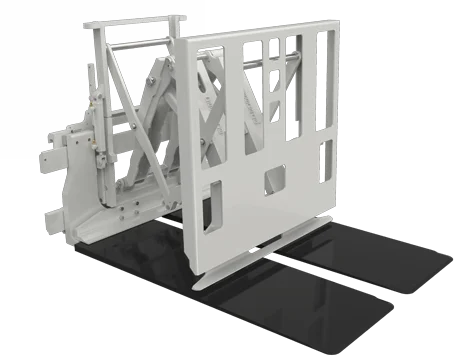

Rotators

Side Shifters Increase Operational Flexibility in Tight Spaces

Side shifters allow the forklift carriage to move left or right, giving the operator the ability to make fine adjustments without repositioning the entire forklift. This feature enhances operational flexibility, especially in narrow aisles, tight loading bays, or crowded storage areas.

The ability to shift the load side-to-side minimizes maneuvering time and helps prevent accidents during load handling. In situations where pallets must be tightly stacked or precisely aligned, side shifters become essential for reducing damage and increasing throughput.

These forklift accessories are ideal for warehouses where space constraints are a constant challenge and where speed and precision directly influence efficiency.

Rotators Simplify the Handling of Large and Awkward Loads

For industries that manage bins, drums, or containers that must be dumped or rotated during production or storage, rotators provide a perfect solution. These specialized forklift attachments allow the carriage to rotate 360 degrees, giving operators the flexibility to reposition loads without manual intervention.

Rotators are widely used in manufacturing, agriculture, recycling, and food processing where materials need to be flipped or emptied. Their utility lies in their ability to minimize manual labor, speed up workflows, and reduce the risk of spills or equipment damage.

Adding a rotator to your forklift transforms it into a versatile tool that can support a wider range of tasks while maintaining safety and speed.

Multi-function Attachments Provide Versatility for Various Tasks

Multi-function attachments are designed to allow a single forklift to perform several tasks without changing equipment. Examples include clamp-and-rotate combinations or fork-and-grab systems. These all-in-one forklift accessories streamline operations by eliminating the need to switch between different attachments.

By investing in multi-function attachments, businesses can reduce their forklift fleet size while increasing the range of work one unit can handle. These accessories improve time efficiency and promote safer handling by reducing the frequency of attachment changes.

Such adaptability is particularly valuable in warehouses or manufacturing environments where product types and handling requirements change frequently.

Multi-function Attachments

Selecting the Right Forklift Accessories for Your Needs

Choosing the best forklift accessories begins with understanding the specific needs of your operation. Factors like load type, frequency of movement, aisle width, operator skill level, and environmental conditions should all be considered.

It’s also essential to consult with manufacturers or experienced providers like Akuros, who can recommend the ideal solution based on technical requirements and usage patterns. Matching the right forklift attachments with your forklift model and intended tasks ensures smooth integration and avoids unnecessary wear or performance limitations.

Evaluating ROI, productivity gains, and safety improvements will guide the investment process and help businesses maximize the value of their material handling equipment.

Installation and Operation Require Proper Planning

Once the correct forklift accessories have been selected, installation should be carried out by qualified technicians. Correct mounting, hydraulic integration, and function testing are essential to ensure the accessory performs reliably and safely.

Operators should also receive training specific to each forklift attachment, covering use, limitations, safety protocols, and maintenance checks. Proper training reduces risk and ensures that the equipment is used to its full potential.

Documentation from manufacturers should always be referenced during installation, and any updates to operating procedures should be communicated to all relevant personnel.

Maintenance and Safety Tips for Long-Term Performance

Routine maintenance is key to extending the life of your forklift accessories and ensuring safe, efficient operation. This includes checking hydraulic connections, inspecting mechanical components for wear, lubricating moving parts, and ensuring proper alignment.

Preventive maintenance schedules should align with usage frequency, environmental exposure, and the type of material handling tasks performed. Safety protocols must include regular operator checks and immediate reporting of any faults or unusual behavior during operation.

Investing in quality accessories, such as those offered by Akuros, reduces maintenance needs, but routine inspections and compliance with safety standards are still essential for long-term efficiency.

Forklift Accessorie

Forklift accessories are more than simple add-ons—they are strategic tools that empower businesses to get the most out of their material handling equipment. From fork positioners and side shifters to rotators and multi-function attachments, the right accessories dramatically improve productivity, reduce damage, and enhance safety in warehouse operations.

When chosen carefully and used properly, forklift accessories can transform a standard forklift into a multi-functional powerhouse capable of handling complex and demanding tasks. Brands like Akuros exemplify what high-quality, innovative attachments can do to support operational goals and adapt to changing logistics needs.

By investing in the right tools, prioritizing safety and maintenance, and training staff effectively, companies can ensure that their forklifts operate at peak performance—with maximum operational flexibility and minimal downtime. In a competitive supply chain environment, every efficiency counts—and with the right forklift accessories, those gains are well within reach.For example: “Want to learn more about Forklift Accessorie purchasing information? Contact us now to get a quote!”

Previous News

Forklift Batteries Powering Warehouse EfficiencyNext News

The Ultimate Guide to Ordinary Beam RacksShare: