AGV automation is not a universal solution for cold storage warehouses. This article provides a practical ROI decision framework to determine when AGVs truly make sense in frozen environments, why many projects fail after deployment, and how a hybrid model combining electric forklifts and AGVs often delivers the most reliable long-term return in cold chain operations.

1. The Automation Myth in Cold Storage Warehouses

Automation is frequently perceived as a guaranteed efficiency upgrade. In cold storage warehouses, however, automation amplifies both strengths and weaknesses of the underlying system.

Frozen environments introduce unique constraints, including limited manual access, higher downtime sensitivity, and increased maintenance complexity at sub-zero temperatures. When automation decisions are made without system-level planning, these constraints often turn minor inefficiencies into structural bottlenecks.

This is why cold storage automation should always be evaluated as part of a one-stop warehouse solution, where layout design, equipment selection, and system integration are developed together rather than treated as isolated upgrades.

2. The Four Conditions That Justify AGV Investment in Cold Storage

2. The Four Conditions That Justify AGV Investment in Cold Storage

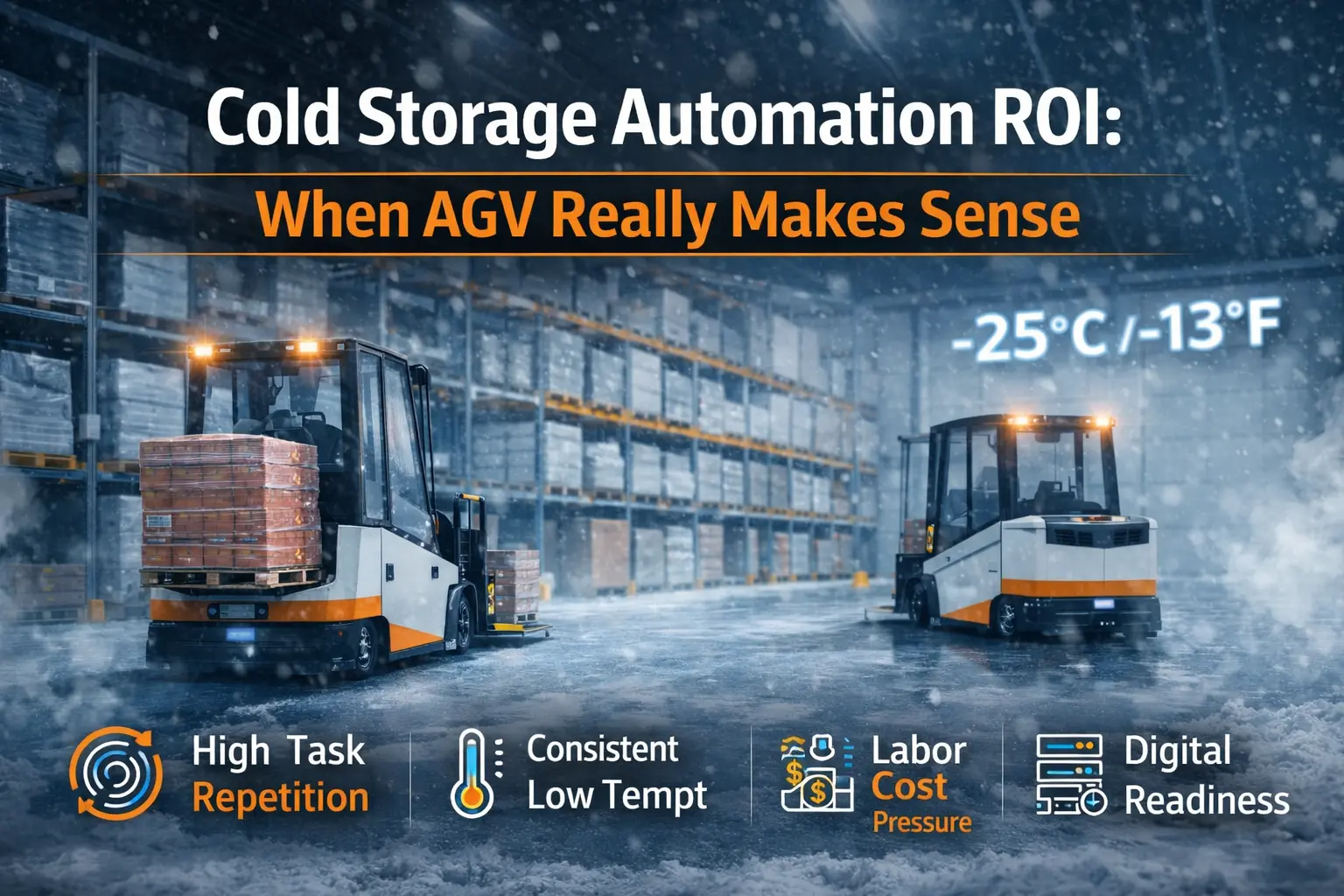

AGVs deliver sustainable ROI only when specific operational conditions are met. Based on real cold chain deployment experience, the following four factors should be considered mandatory rather than optional.

2.1 High Task Repetition and Stable Material Flow

AGVs perform best in environments with predictable and repetitive transport cycles, such as pallet transfers between inbound staging areas and fixed storage zones. Cold storage warehouses with stable SKU profiles and consistent routing logic allow AGVs to operate at high utilization rates.

In contrast, facilities with frequent layout changes or highly dynamic order profiles often experience delayed payback periods and increased system complexity.

2.2 Consistent Low-Temperature Operation

AGV automation is most effective in cold storage facilities operating continuously at temperatures between -18°C and -30°C. Stable frozen conditions reduce environmental variability once systems are calibrated and allow automation to outperform manual operations over extended shifts.

Intermittent cold rooms with frequent temperature transitions increase condensation risk and place additional stress on batteries and electronic components, reducing automation reliability.

2.3 Labor Cost Pressure and Workforce Availability

AGV ROI improves significantly in regions where labor costs are rising or skilled operators are increasingly difficult to recruit. This dynamic is particularly relevant for cold chain operations in North America, Australia, and parts of Europe, where workforce stability has become a strategic risk factor.

In these markets, automation is often driven less by headcount reduction and more by operational continuity and risk mitigation.

2.4 Digital Readiness and System Integration Capability

AGVs should never operate in isolation. Successful cold storage automation depends on digital readiness, including task orchestration, inventory visibility, and real-time equipment coordination. Facilities that deploy AGVs without a stable warehouse management framework frequently encounter inefficiencies rather than productivity gains.

This is why AGV projects achieve better outcomes when integrated into a broader automated warehouse solution that aligns software logic with physical material flow.

3. Expert Insights from Cold Chain Automation Projects

Expert Insight — Cold Chain Automation Engineer (North America)

“Most failed AGV projects didn’t fail because of technology. They failed because the warehouse layout and material flow were never designed for automation in the first place.”

Expert Insight — 3PL Operations Director (Europe)

“AGVs are excellent for repetitive transport in frozen warehouses, but expecting them to replace all forklifts is unrealistic and often counterproductive.”

These insights highlight a consistent pattern across regions: automation succeeds when it complements operational reality rather than attempts to replace it entirely.

4. The Hybrid Automation Model: AGV and Electric Forklift Working Together

Rather than choosing between automation and conventional equipment, many successful cold chain facilities adopt a hybrid automation model. In this approach, AGVs handle repetitive, long-distance transport tasks, while electric forklifts designed for cold storage environments manage exception handling, mixed SKUs, and high-density picking operations.

This division of labor allows warehouses to maintain flexibility without sacrificing efficiency. Hybrid models are particularly effective in facilities that combine fixed transport routes with dynamic order fulfillment requirements, reducing system rigidity while preserving automation benefits.

5. ROI Calculation Framework for Cold Storage Automation

A realistic ROI evaluation for cold storage automation must consider both direct and indirect performance drivers.

Direct ROI Drivers

-

Reduced labor dependency in repetitive transport tasks

-

Improved throughput consistency across multiple shifts

-

Lower handling error rates in fixed workflows

Indirect ROI Drivers

-

Reduced operator exposure to extreme low temperatures

-

Improved compliance with cold chain safety standards

-

Lower accident risk in high-traffic frozen environments

Warehouses that assess automation solely on labor replacement often underestimate the value of system stability and risk reduction, leading to unrealistic payback expectations.

6. Where Cold Storage Automation Commonly Fails

Automation projects underperform most often when AGVs are introduced without alignment between storage design and equipment capability. In cold storage facilities that rely on high-density racking systems, such as double deep racking solutions or drive-in racking systems, automation risks increase significantly if aisle geometry, reach requirements, and traffic logic are not planned together.

Once these systems are installed without coordination between racking layout and automation paths, throughput loss and congestion become structural issues that are difficult to resolve without major redesign.

7. Why End-to-End Planning Delivers Better Automation ROI

Cold storage automation consistently delivers stronger ROI when developed as part of an end-to-end system. This includes coordinated planning of layout design, racking configuration, equipment selection, automation logic, and long-term service strategy.

By treating automation as a component of a unified warehouse ecosystem rather than a standalone upgrade, operators reduce integration risk and improve long-term operational resilience.

8. Google Popular Topics (Contextual Answers)

Is AGV automation suitable for all cold storage warehouses?

No. AGVs perform best in stable, repetitive workflows supported by strong digital infrastructure and well-defined material flow.

What temperature can AGVs operate at in cold storage?

Many cold storage AGVs are engineered to operate reliably at temperatures down to -25°C, depending on battery chemistry and component protection.

Can AGVs fully replace forklifts in frozen warehouses?

In most cases, no. A hybrid AGV and electric forklift model provides better flexibility and risk control.

How long does it take to achieve ROI from cold storage automation?

Typical ROI periods range from two to five years, depending on labor costs, throughput levels, and system stability.

Does automation reduce energy consumption in cold storage?

Indirectly, yes. Improved handling efficiency can reduce door-open time and unnecessary temperature fluctuations.