In today’s fast-paced logistics and manufacturing environments, every second matters. As warehouses face increasing pressure to move more goods in less time, forklift attachments have become one of the most impactful ways to elevate material-handling efficiency without investing in additional equipment.

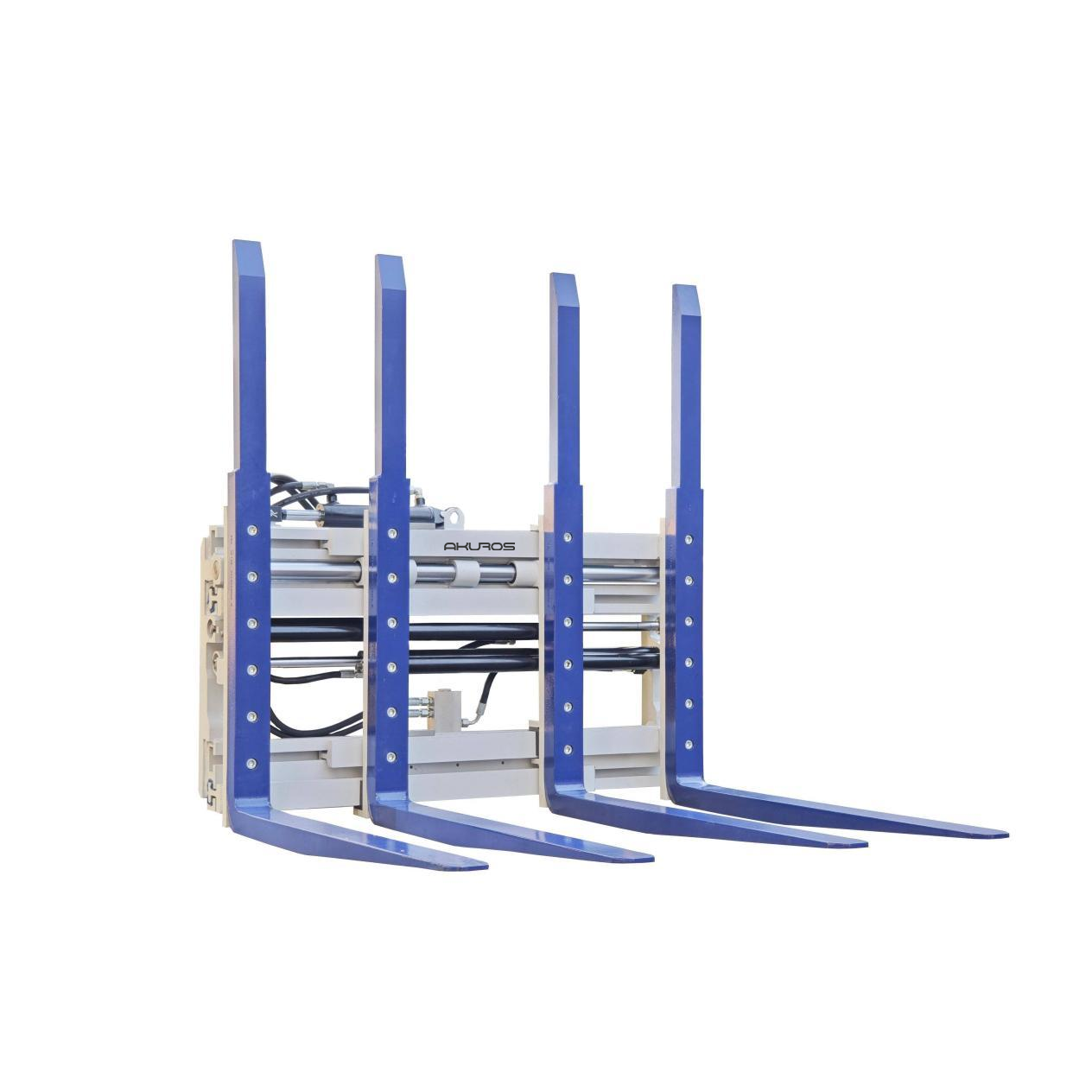

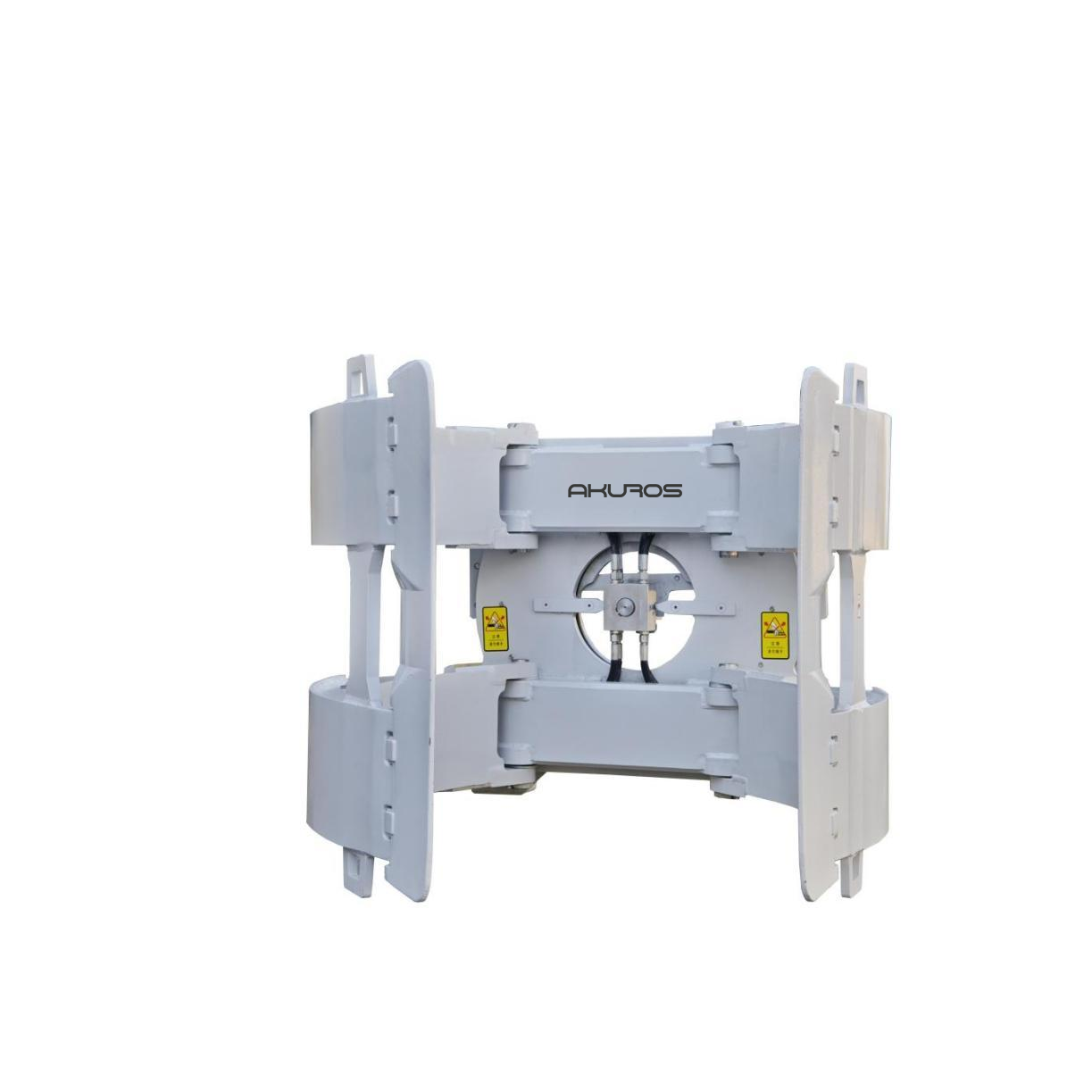

Akuros forklift attachments—ranging from fork positioners and side-shifters to paper roll clamps, carton clamps, and single-double pallet handlers—provide measurable improvements in speed, safety, and accuracy. This article explores how these attachments support real-world operations and deliver a high long-term return on investment (ROI).

1. Why Forklift Attachments Matter More Than Ever

1. Why Forklift Attachments Matter More Than Ever

Modern warehouses deal with heavier workloads, tighter delivery windows, and rising labor costs. Forklift attachments allow businesses to:

-

Handle diverse materials with one forklift

-

Reduce pallet-handling time

-

Lower labor intensity and operator fatigue

-

Prevent product damage through precision control

-

Increase warehouse throughput without expanding fleet size

Instead of purchasing more forklifts, companies can leverage attachments to enhance existing equipment—resulting in a faster, more cost-effective upgrade path.

2. Real Use Cases: How Akuros Attachments Transform Productivity

2. Real Use Cases: How Akuros Attachments Transform Productivity

Case 1: Beverage Distribution – Doubling Throughput With Single-Double Pallet Handlers

A beverage warehouse handling bottled drinks switched from standard forks to Akuros Single-Double Pallet Handlers.

Results:

-

2 pallets moved at once instead of one

-

Loading/unloading time reduced by 45%

-

Forklift utilization improved by 35%

-

Reduced fuel and labor costs by eliminating unnecessary travel cycles

This directly increased outbound shipment capacity during peak seasons.

Case 2: Paper Industry – Zero-Damage Handling With Paper Roll Clamps

Case 2: Paper Industry – Zero-Damage Handling With Paper Roll Clamps

A paper manufacturer struggled with roll deformation caused by improper forklift handling.

After adopting Akuros Paper Roll Clamps:

-

Product damage dropped by 70%

-

Handling speed increased due to 360° rotation and secure grip

-

Operators achieved higher accuracy under tight stacking conditions

This saved the customer substantial costs previously lost to damaged inventory.

Case 3: Cold Storage – Reliable Performance With Corrosion-Resistant Attachments

Cold storage environments accelerate equipment corrosion and reduce hydraulic performance.

With Akuros’ galvanized and stainless-steel options:

-

Attachments operated smoothly at temperatures as low as –25°C

-

Corrosion-related failures decreased significantly

-

Reduced maintenance downtime improved overall throughput

The warehouse extended equipment lifespan by more than 30%.

3. ROI Analysis: The Financial Impact of Akuros Attachments

✔ Lower Operational Costs

Attachments reduce forklift cycle time, meaning fewer travel routes and shorter operating hours.

This translates into:

-

Lower electricity or fuel consumption

-

Reduced labor hours

-

Less wear on forklift components

✔ Higher Productivity With the Same Fleet

Instead of adding three new forklifts, one attachment can accomplish the same workload.

The cost difference is significant:

-

A forklift might cost $12,000–$25,000

-

A high-performance attachment costs a fraction of that

Customers typically see ROI within 6–12 months.

✔ Reduced Product Damage

Carton clamps, roll clamps, and side-shifting positioners ensure precise handling, significantly lowering breakage, crushing, or deformation.

Less product damage = higher profit retention.

✔ Longer Equipment Lifespan

Akuros attachments use high-quality steel, anti-corrosion coatings, IP-rated electronics, and reinforced hydraulics.

This results in:

-

Fewer breakdowns

-

Fewer replacement parts

-

More predictable maintenance costs

4. Industries That Benefit the Most

-

Food & beverage logistics

-

Cold storage

-

E-commerce fulfillment centers

-

Manufacturing & industrial plants

-

3PL warehouses

-

Paper and packaging industry

-

Retail distribution hubs

Any business prioritizing speed, accuracy, and cost efficiency will see a substantial boost by integrating Akuros forklift attachments.

5. The Akuros Advantage

Akuros attachments are engineered for:

-

Strength under continuous heavy-duty cycles

-

Precision proportional control

-

Smooth hydraulic flow management

-

High visibility for safer operations

-

Compatibility with major forklift brands

Customers trust Akuros for consistent performance, long product life, and industry-leading ROI.

6. Conclusion: A Smarter Path to Warehouse Optimization

Investing in Akuros forklift attachments is not just a cost—it is a strategic upgrade that unlocks higher productivity across the entire warehouse.

With faster handling speeds, reduced product damage, improved operator safety, and measurable cost savings, Akuros attachments provide a clear path to better fleet performance and stronger business results.

Whether you operate a cold storage facility, an industrial plant, or a modern distribution center, upgrading your forklifts with the right attachments can deliver immediate and long-lasting benefits.