In the age of intelligent logistics dan smart automated warehousing, achieving fully unmanned automation is no longer a futuristic goal—it’s happening now. Yet behind every seamless operation lies one of the biggest engineering challenges: the precise and efficient docking of multiple automated systems.

In a modern automated warehouse, equipment diversity is immense—AGVs, conveyor lines, robotic arms, lifts, shuttles, and more must work together to move goods efficiently. However, each type of machine follows different docking mechanisms, creating a web of complex interconnections that demand precise control, synchronization, and safety.

This article explores the core logic, challenges, and solutions in achieving a unified, flexible docking system—one that enables different automated devices to communicate, cooperate, and operate seamlessly in a high-efficiency warehouse environment.

🚀 The Complexity of Automated Docking in Modern Warehouses

In a multi-device logistics system, collaboration between robots is essential for a single material-handling process. Let’s look at some common docking scenarios:

-

A CTU robot transfers bins to and from a conveyor line

-

An AGV delivers or receives pallets from a pallet conveyor

-

An AGV docks with a lift system to transfer goods between floors

-

A robotic arm picks boxes from a conveyor and places them onto an AGV pallet

-

Multiple AGVs coordinate at the same loading zone

Each of these scenarios involves real-time communication, safety assurance, and spatial precision. Poor synchronization could cause collisions, jams, or downtime, leading to serious operational consequences.

⚙️ What Is a Docking Station?

A docking station is the physical point where two devices exchange goods or containers. It could also serve as a human-robot interaction zone in hybrid warehouses.

For a docking station to function effectively, it must satisfy two key requirements:

-

Positioning Precision – both devices must reach the same physical coordinates accurately.

-

Process Control Logic – a defined sequence of operations dictates which device moves first, how the handoff occurs, and how safety is maintained.

However, as the diversity of warehouse devices increases, so does the complexity of docking logic. If every device combination requires its own protocol, the system becomes fragmented and difficult to maintain.

Di sinilah flexible docking logic comes into play—a universal communication and control model that can adapt to various equipment types and configurations.

🧩 Flexible vs. Rigid Docking: A Case Study

Consider a common scenario:

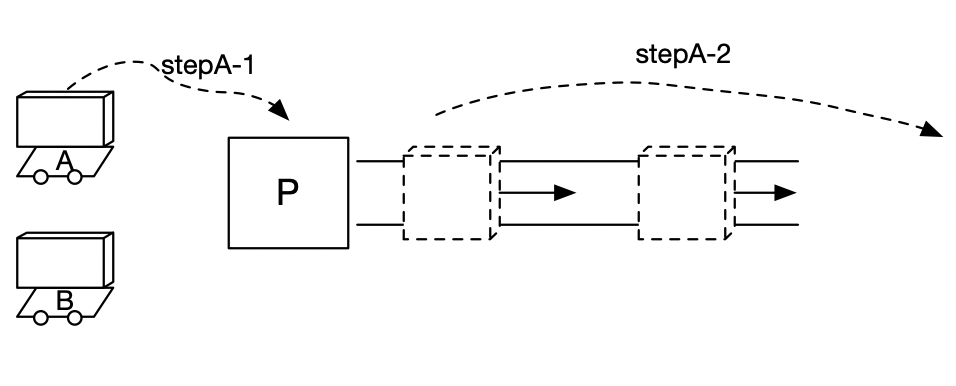

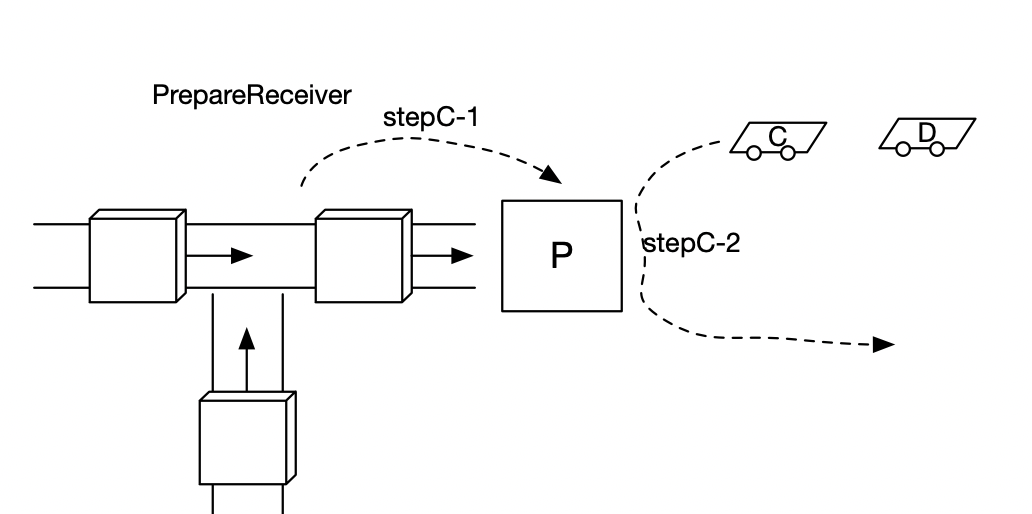

An AGV (flexible device) must transfer a pallet to a conveyor line (rigid device).

1️⃣ Pre-Docking Phase

Before the transfer begins, multiple AGVs may need to deliver pallets to the same point. Since they travel different distances and face unpredictable traffic, dynamic scheduling is required to decide which AGV docks first.

This is a localized swarm-decision problem, balancing both speed and efficiency. Idle AGVs must also reposition strategically to avoid blocking paths or wasting travel time.

When the situation is reversed—i.e., the conveyor line delivers to the AGV—the AGV should wait near the docking area, ready to respond as soon as the conveyor signals that a pallet is available. This reduces latency and keeps throughput high.

🔄 The Docking Process: Synchronization in Motion

During docking, both systems must reach the exact physical interface simultaneously. There are typically two approaches:

-

Synchronous motion docking: both devices move together, as in rolling conveyors. Here, the receiving side should start slightly earlier to prevent jamming.

-

Sequential docking: one device sets down the load, and the other picks it up afterward. This requires precise timing and stable positioning.

Safety remains the top priority. Misalignment or poor coordination can cause mechanical damage or workflow interruptions.

✅ Post-Docking: Clearing the Way for Efficiency

Once docking is complete, the AGV must depart quickly to clear the space for the next unit. Delays at the docking point can lead to traffic congestion, reducing the overall efficiency of the system.

Therefore, route planning and departure logic are integral to the overall docking design. AGVs can be programmed to move to nearby rest positions or immediately begin their next task, depending on workload and scheduling priorities.

⚡ Efficiency Optimization Strategies

To maintain high throughput under large-scale operations, a smart warehouse must go beyond mechanical coordination—it needs intelligent scheduling and predictive control. Key strategies include:

1. High-Priority Dispatching

When AGVs interact with conveyors or lifts, assigning high-priority AGVs to remove pallets quickly prevents bottlenecks and ensures continuous material flow.

2. Proactive Power Allocation

Prepare AGVs in advance near busy docking points to minimize travel distance. Predictive algorithms determine the best timing for pre-positioning—too early wastes capacity, too late causes delays.

3. Timely Departure After Delivery

Once a pallet is delivered, the AGV should return to a standby zone or pick up a new task immediately. This keeps the fleet dynamic and avoids idle blocking at critical intersections.

4. Docking Point Selection

If multiple docking options exist (for example, multiple lifts for inter-floor transport), an adaptive docking selection algorithm prioritizes the station with the lowest current workload.

🗺️ Layout and Map Optimization

Effective warehouse map design is essential for smooth docking operations. A well-planned layout supports coordinated movement, avoids congestion, and enhances overall system stability.

Key layout design elements include:

• Queue Zones

Pre-docking queue zones help AGVs line up in order, maintaining orderly access to busy docking stations and preventing chaos during peak periods.

• Separate Waiting Areas

When a station has a single entry and exit, buffer waiting areas are critical to prevent traffic jams and support continuous flow.

• Rest Zones

Resting spots near docking areas allow AGVs to remain on standby, minimizing reaction time and improving fleet responsiveness when new tasks are issued.

These layout principles are part of Akuros’ intelligent warehouse planning system, where universal docking logic works hand-in-hand with map optimization to deliver maximum efficiency and flexibility.

🤖 Why Flexible Docking Matters for the Future

As automation technologies advance, rigid, single-purpose connections are giving way to modular, flexible systems that can handle a wide range of goods and workflows. Flexible docking allows:

-

Seamless coordination among multiple automation systems

-

Faster adaptation to layout or product changes

-

Reduced system downtime

-

Higher safety and operational reliability

With Akuros’ automated warehouse solutions, enterprises can achieve a new level of warehouse intelligence—where every AGV, lift, and conveyor communicates through a unified logic system, creating a truly flexible, efficient, and safe automated environment.

💬 Conclusion

Building an unmanned automated warehouse is not just about robots—it’s about enabling those robots to collaborate intelligently. Through flexible docking logic, predictive scheduling, and layout optimization, logistics operations can achieve real-time efficiency, safety, and scalability.

Di Akuros, we continue to push the boundaries of warehouse automation—delivering solutions that redefine how equipment connects, communicates, and cooperates in the era of smart logistics.