- Trustpilot

Drive-in Racking System

Tailored Racking Solutions

Space Optimization

High Storage Density

Easy Operation

Safety and Durability

Partial Drive-in Racking System Gallery

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |

Get Your Drive-in Racking Solution Now

Not sure which drive-in racking system suits your warehouse best?

- Every unit undergoes rigorous testing before delivery to guarantee safety, reliability, and long-term use.

- We offer competitive factory-direct prices and flexible customization options to meet different budgets and application requirements.

- Our professional technical team provides comprehensive after-sales service, including installation guidance, spare parts supply, and long-term maintenance support—so you can operate with confidence.

Send your custom needs

Drive-in Racking System Process

Design Planning

We identify your warehouse needs and outline the system’s key specs.

Project Development

Our team designs and prototypes a system tailored to your layout and requirements.

Production

We manufacture robust components and assemble the racking system.

Quality Control

We conduct thorough tests to ensure quality and safety.

Logistics Management

We plan and execute distribution to ensure on-time, damage-free delivery.

Customer Training

We train your team for safe operation and maintenance.

Our Commitment to Excellence

Customer Service

Technical Support

Project Management

Specialist industries

Food & Beverage

E-commerce Logistics

Retail

Healthcare

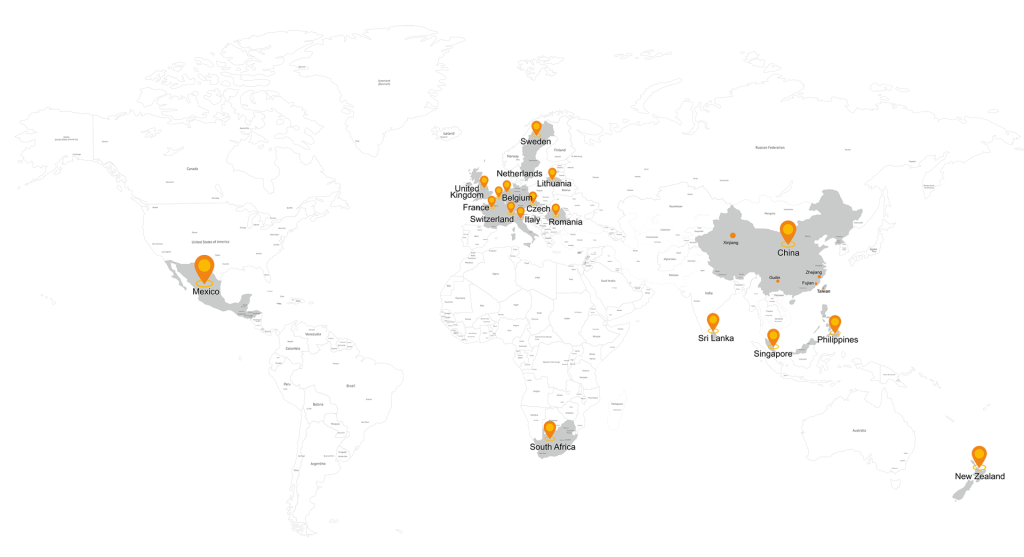

Akuros Global Market

Akuros Advantage

Success Stories

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |

Based on 645 reviews

- Trustpilot

Maximized Warehouse Productivity

Streamlined Warehouse Processes

Eco-Friendly and Cost-Effective Systems

The Akuros Drive-in Racking System Handbook

Akuros Drive-in Racking Systems Resources

Introductory guides

- Understanding Drive-in Racking Basics

- Introduction to Racking System Operations in Drive-in Systems

- Getting Started with Drive-in Warehouse Storage Solutions

Design guides

- Key Design Considerations for Drive-in Racking

- Drive-in Racking System Safety Design Guidelines

- Fundamentals of Maintenance and Care for Drive-in Racking Systems

Applications

- Drive-in Racking Applications in Warehousing

- Drive-in Racking Applications in Manufacturing

- Drive-in Racking Applications in Logistics

Usage Guidelines

- Troubleshooting Drive-in Racking System Issues

- Optimizing Drive-in Racking System Performance

- Maximizing Storage Efficiency with Drive-in Racking Systems

Boosting Warehouse Productivity with Drive-in Racking

Read Case Study

Read Case Study

Read Case Study

Read Case Study

Read Case Study

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |

What can you achieve with Akuros drive-in racking systems?

Our drive-in racking systems enable faster and more efficient storage and transportation of goods, significantly boosting warehouse operation speeds and reducing manual labor.

With innovative designs tailored for diverse warehouse layouts, our systems help businesses optimize space utilization, enhancing storage density and organization.

Equipped with advanced safety features and built for stable performance, our systems minimize accident risks, helping businesses maintain a safer and more compliant working environment.

Using durable materials, efficient energy consumption, and low maintenance requirements, our systems help cut long-term ownership and daily operational costs.

As your business grows, our systems provide the necessary performance, reliability, and customization to support smooth and sustainable operational expansion.

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |