- Trustpilot

Akuros Automation & AGV

Capabilities of Akuros Automation & AGV

Smooth Operation

Advanced Safety Systems

● Alarms and warnings: promptly alert the operator to potential risks.

● Emergency brake: quickly stop the truck in an emergency.

Efficient Space Utilization

High Load Handling

● Flexible load adaptability: Easily adapts to a wide range of load capacities.

● Load placement: Precisely positions loads to reduce the risk of damage.

Contact Us for Custom Solutions

Find Your Ideal Automation & AGV

- Fit your specific needs with our tailored solutions.

- Rigorously tested for reliability in various conditions.

- Manufacturer - direct, flexible options to suit your budget.

- Full maintenance and service to ensure long - term performance.

Send your custom needs

From Concept to High - Efficiency Operation

Needs Assessment

Analyze warehouse needs and operational goals.

Conceptual Design

Develop innovative solutions for modern warehouse challenges.

Prototyping

Create and test prototypes to validate functionality.

User Feedback

Refine designs based on user feedback and ergonomic testing.

Final Validation

Conduct real - world testing to ensure reliability.

Deployment

Provide installation support and customized training.

Automation & AGV Fleet -Quality You Can Trust

Smart Operation

Energy Efficiency

Ergonomic Design

Specialist industries

Manufacturing

Logistics Centers

E - commerce

Food and Beverage Industry

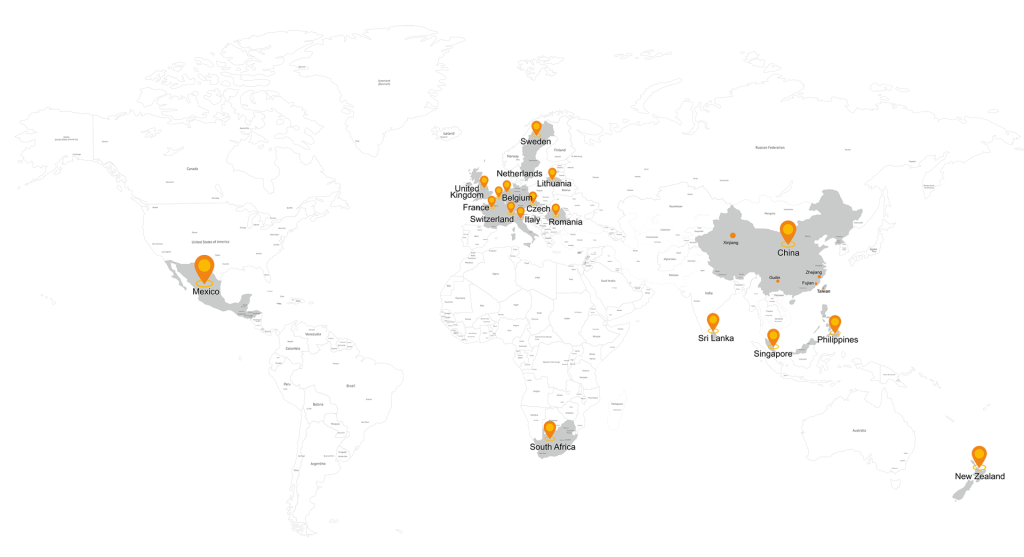

Akuros Global Market Reach

Akuros Advantages

Collaborative Partnerships Driving AGV Innovation

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |

Based on 632 reviews

- Trustpilot

Enhanced Warehouse Productivity

Streamlined Warehouse Operations

Cost - Efficient Warehouse Solutions

Automation & AGV Operator's Guide

Learning and Support Resources

Getting Started Guides

- Introduction to Automated Warehouses

- AGV Operation Basics

- AGV System Configuration Guide

Operational Manuals

- AGV Daily Operation Manual

- AGV Maintenance Manual

Basics of Warehouse Material Handling

- Modern Warehouse Logistics Processes

- Applications of AGV in Material Handling

AGV Operation and Safety Manual

- AGV Safe Operation Standards

- AGV Accident Prevention and Emergency Response

Enhancing Warehouse Efficiency

Read Case Study

Read Case Study

Read Case Study

Read Case Study

Read Case Study

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |

How Akuros AGV Can Benefit You

Akuros AGV are designed to enhance efficiency and safety in warehouse environments. They offer significant advantages that can transform your operations. With their advanced features and robust design, these vehicles are built to streamline workflows and optimize storage utilization.

They accelerate loading, unloading, stacking, and transportation of goods, minimizing manual labor and speeding up warehouse processes. Their high – reach capabilities and narrow – aisle design maximize storage space, allowing for higher storage density and better space utilization.

Safety is a paramount concern, and Akuros AGV come equipped with state – of – the – art safety features. These ensure stable operation in various conditions, reducing accident risks and creating a safer working environment for your team.

Moreover, these vehicles are cost – effective, combining energy – efficient motors and low maintenance needs to reduce long – term operational expenses. As your business grows, their scalability and flexibility allow for seamless expansion of your warehouse operations.

| Product | Specification | Application |

|---|---|---|

| Electric | 1.5T, 3m Lift | Warehouse |

| IC | 3T, 4.5m Lift | Logistics |

| Reach | 1T, 5m Lift | Retail |

| Type | Capacity | Suitable |

|---|---|---|

| Lead Acid | 80V/200Ah | 1-3T Forklifts |

| Lithium | 48V/400Ah | 1-2T Forklifts |

| NiMH | 72V/150Ah | 1-2T Forklifts |

| Type | Size | Surface |

|---|---|---|

| Solid | 28×9-15 | Rough |

| Pneumatic | 23×8-12 | Smooth |

| Polyurethane | 35×12-19 | Mixed |

| Attachment | Suitable | Function |

|---|---|---|

| Side Shifter | 1-3T | Flexibility |

| Rotater | 2-5T | Narrow Aisles |

| Counterweight | All | Stability |

| Equipment | Function | Use Case |

|---|---|---|

| Bumper Post | Collision | Warehouse |

| Safety Belt | Operator | All Forklifts |

| Mirror | Visibility | All Forklifts |