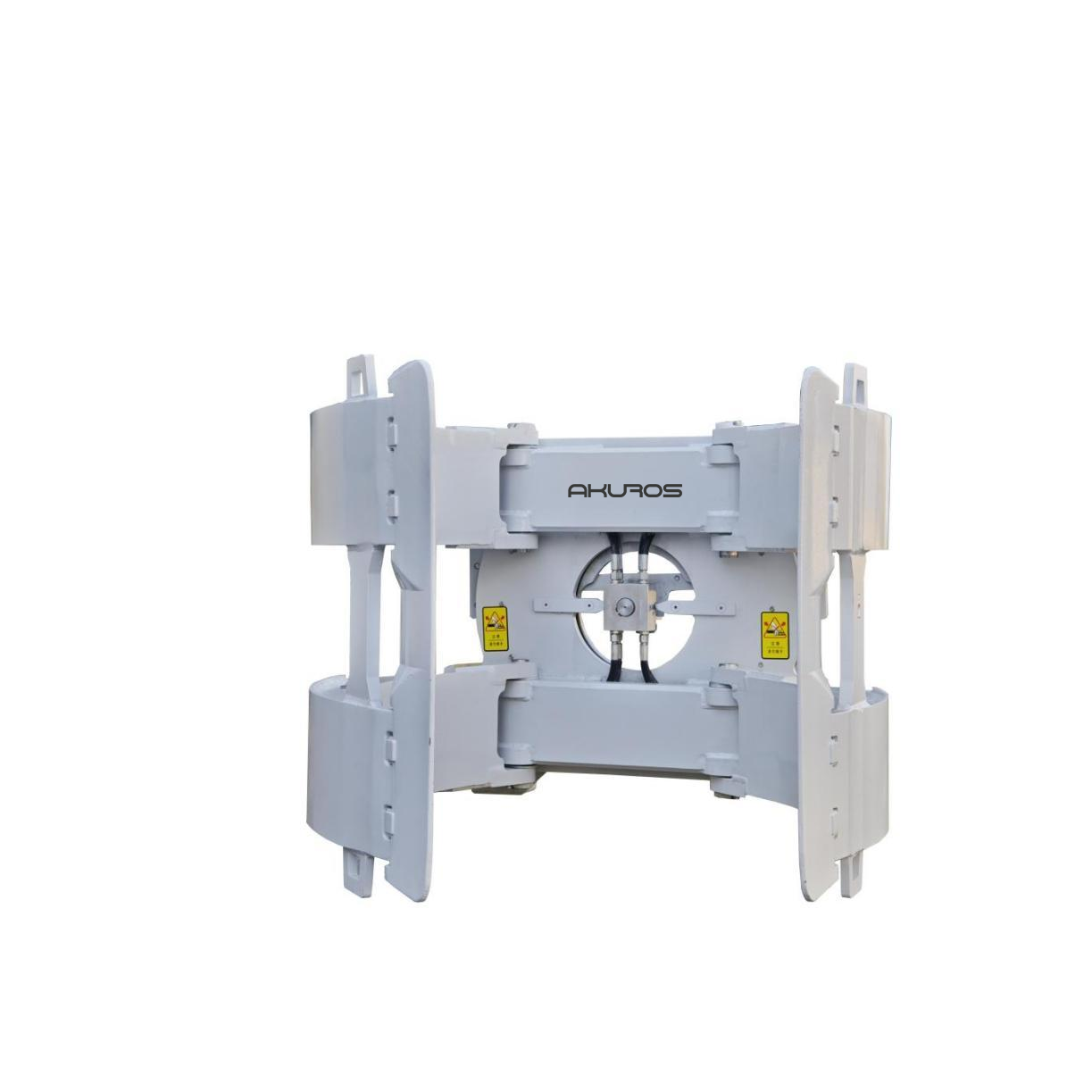

» Akuros K-Series Sideshifting Fork Positioner

Heavy-Duty • High-Strength • Built for Demanding Applications

The Akuros K-Series Sideshifting Fork Positioner is engineered for operations requiring strong clamping power, wide fork-adjustment range, and reliable sideshifting performance under heavy loads. With a reinforced frame, optimized hydraulic system, and robust structural design, the K-Series delivers exceptional durability and stability in high-intensity working environments.

Designed for forklifts handling mixed pallet sizes, irregular loads, or large-volume goods, the K-Series enhances material-handling efficiency while significantly improving operator precision and safety.

Product Overview

The K-Series is a high-strength fork positioner capable of handling continuous, heavy-duty pallet operations. Its powerful shifting mechanism allows operators to adjust fork spacing from the driver’s seat—no manual labor required. Combined with smooth sideshifting and excellent fork visibility, it enables fast, accurate load positioning even in tight warehouse aisles.

The attachment is well-suited for industries such as manufacturing, logistics, beverages, construction materials, food cold chains, and high-cycle distribution centers where reliability and endurance are critical.

Key Features

✔ Reinforced High-Strength Frame

Built from heavy-duty steel and engineered for long-term durability, the K-Series withstands frequent impact, high lifting capacities, and demanding daily operations.

✔ Wide Fork Adjustment Range

Hydraulic positioning allows forks to open or close smoothly across a large range, enabling the forklift to handle:

-

mixed pallet sizes

-

oversized goods

-

shrink-wrapped or irregular loads

This eliminates the need for manual repositioning and reduces handling time.

✔ Smooth Hydraulic Sideshifting

Operators can shift loads left or right with precision, improving pallet alignment and reducing steering corrections. This is especially beneficial in congested warehouse environments.

✔ Optimized Visibility for Safer Operation

The open-structure design improves the operator’s view of the load, forks, and rack interfaces, reducing the risk of impacts, damage, or misalignment.

✔ Superior Wear Resistance

Heavy-duty slider materials and high-quality hydraulic components reduce friction, minimize maintenance frequency, and extend the attachment’s service life.

✔ Easy Installation and Wide Compatibility

Designed to fit most ISO-standard forklift carriages.

The K-Series can be installed or removed quickly, reducing downtime and improving fleet flexibility.

Applications

The Akuros K-Series is ideal for:

-

High-density warehouses

-

Construction materials & timber handling

-

Food & beverage logistics

-

Port terminals & outdoor yards

-

Manufacturing & assembly plants

-

Cold chain operations

Its heavy-duty construction allows it to excel where traditional fork positioners struggle—especially when handling heavy, wide, or unstable loads.

Operational Advantages

-

Reduces labor cost by eliminating manual fork adjustment

-

Improves load stability and reduces product damage

-

Boosts pallet-handling speed and overall workflow productivity

-

Enhances safety through better visibility and controlled movement

-

Provides long service life with minimal maintenance needs

-

Maximizes fleet versatility by adapting one forklift to multiple load types

Why Choose Akuros K-Series Attachments?

Akuros attachments are engineered to deliver professional-grade performance with a focus on reliability, structural strength, and precision control. The K-Series continues this philosophy by offering:

-

industry-leading durability

-

stable hydraulic performance

-

strong load retention

-

exceptional long-term value

This makes it an ideal solution for companies seeking to upgrade forklift productivity, reduce downtime, and improve operational efficiency.