In today’s fast-paced logistics environment, warehouse operations are under increasing pressure to be faster, safer, and more efficient. The rise of e-commerce, cold chain logistics, and high-volume distribution has transformed traditional warehouses into high-tech, automated spaces. Akuros Intelligent Automated Warehouse Systems are designed to meet these demands, providing flexible, reliable, and high-density storage solutions for a wide range of industries. From cold storage warehouses to e-commerce fulfillment centers, Akuros solutions optimize operations, reduce labor costs, and improve inventory accuracy.

Why Automated Warehouse Systems Matter

Automated warehouse systems integrate transportation, computer, and communication systems to handle goods with minimal manual intervention. Operators input inventory information, and intelligent systems guide vehicles—such as pallet shuttles, automated stackers, or conveyors—to store or retrieve items efficiently.

The main advantages of implementing an automated warehouse system include:

- Intelligent decision-making in logistics operations – The system can optimize routing, storage, and retrieval based on real-time data.

- Integrated warehouse processes – From receiving and storage to order picking, packaging, and dispatch, automated systems streamline all operations.

- Customer-centric flexibility – Warehouses can quickly adjust to changing product demands, seasonal spikes, or personalized order requirements.

- Optimized resource allocation – Maximize space utilization and operational efficiency while minimizing labor costs.

Types of Akuros Automated Warehouse Systems

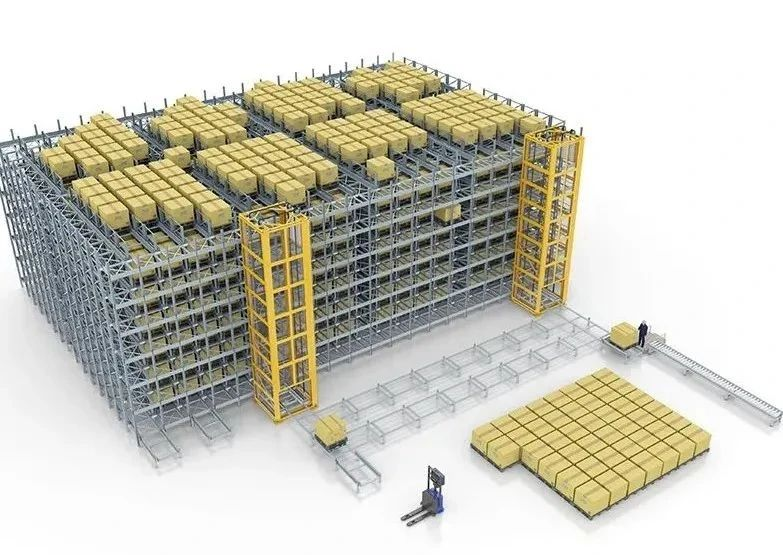

- Pallet Shuttle Warehouse System

Die pallet shuttle system uses pallets as storage units. Operators place goods in shuttle racks, and automated shuttles move items along tracks within the racks. These shuttles handle bidirectional travel, transporting goods from the outer aisle to the inner storage zone, or vice versa.

Hauptmerkmale:

- High-density storage with minimal aisle space.

- Suitable for cold storage or freezing environments, as shuttles are designed to operate reliably at low temperatures.

Ideal Industries:

- Bulk storage of frozen foods, raw materials, or large-volume goods.

Akuros Advantage:

- Akuros pallet shuttle systems integrate seamlessly with WMS/WCS management platforms, enabling automated tracking and inventory control even in high-turnover cold storage facilities.

- Pallet-Based Automated Warehouse

This system combines four-way shuttles, fast vertical lifts, horizontal conveyors, and high-rise racks, all orchestrated through WMS/WCS software. Goods can be stored and retrieved in either FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) order, depending on operational requirements.

Hauptmerkmale:

- Storage heights up to 22 meters, maximizing warehouse space.

- Handles 45–50 pallets per hour, ensuring fast throughput during peak periods.

Ideal Industries:

- E-commerce fulfillment, fast-moving consumer goods (FMCG), and high-volume distribution centers.

Akuros Advantage:

- Akuros’ pallet-based warehouses feature intelligent shuttle routing and lift coordination, enabling high-density storage without sacrificing speed or accuracy.

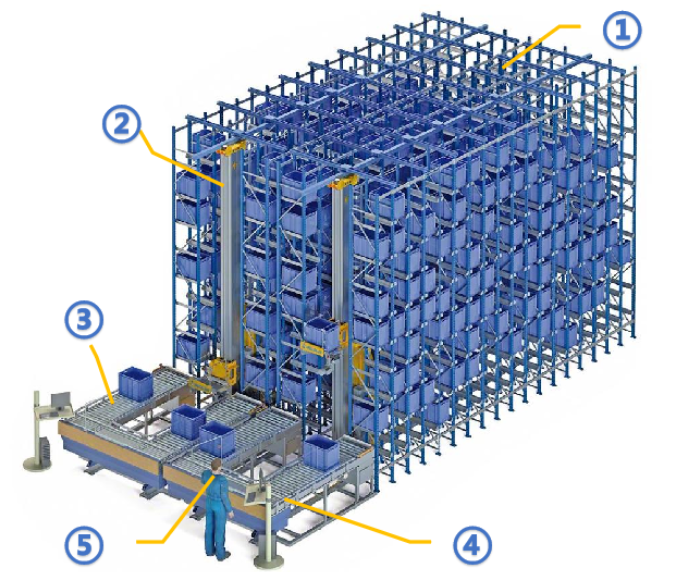

- Tote-Based Automated Warehouse

Unter tote-based storage systems, small bins or containers replace pallets as storage units. Stackers or shuttle vehicles handle the bins, automatically tracking each item for FIFO operation.

Hauptmerkmale:

- Capable of handling multiple product types simultaneously.

- Each aisle can process up to 200 totes per hour.

Ideal Industries:

- Small-batch production, spare parts storage, electronics components.

Akuros Advantage:

- Integrated sensors and WMS/WCS software ensure each tote’s location and movement are tracked in real-time, improving inventory accuracy.

- Automated Carousel Warehouse

Automated carousel systems rotate shelves electronically, bringing goods directly to the operator at a fixed picking station. Carousels can reach speeds up to 30 meters per minute.

Hauptmerkmale:

- Drastically reduces picker travel time.

- High throughput: a single workstation can handle up to 400 items per hour.

Ideal Industries:

- Electronics, precision instruments, and other high-value small items.

Akuros Advantage:

- Akuros carousels integrate with inventory management systems for seamless picking, reducing errors and improving worker ergonomics.

Enhancing Cold Chain Operations with Akuros

Cold storage warehouses have unique challenges: low temperatures, high humidity, and slippery surfaces. Automated systems like Akuros pallet shuttle warehouses or pallet-based systems work seamlessly with cold chain equipment, such as the Akuros T20B electric pallet truck und E16 electric stacker, ensuring:

- Consistent operation at low temperatures.

- Corrosion-resistant design to withstand moisture and salt exposure.

- Smooth, precise movement for fragile goods.

FAQ - Häufig gestellte Fragen

Q1: Which Akuros system is best for cold storage warehouses?

A1: Pallet shuttle or pallet-based systems are ideal for cold storage due to their high-density, automated handling capabilities and compatibility with cold chain vehicles like T20B and E16.

Q2: Can Akuros handle both high-volume and small-batch operations?

A2: Yes. Tote-based or carousel systems are suitable for small-batch, multi-product operations, while pallet-based solutions excel in bulk or high-frequency scenarios.

Q3: How does Akuros integrate with WMS/WCS?

A3: All systems can be seamlessly integrated with Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS), providing real-time inventory tracking, reporting, and operational optimization.

Q4: Are Akuros systems energy-efficient?

A4: Yes. Electric shuttles and automated lifts reduce energy consumption and eliminate emissions, even in cold storage environments.

Interactive Questions for Visitors

- Is your warehouse struggling with high labor costs or limited space?

- Do you face operational challenges in cold storage or high-density environments?

- Could automated warehouse solutions help improve your throughput and reduce downtime?

By exploring Akuros solutions, warehouse operators can answer these questions and identify the best system for their business.

Schlussfolgerung

The choice of automated warehouse system depends on your product type, business scale, and operational efficiency goals. Akuros Intelligent Warehouse Systems bieten:

- Higher density storage.

- Faster in/outbound operations.

- Lower labor costs and energy consumption.

- Improved inventory accuracy and operator safety.

Whether you manage a cold chain facility, e-commerce warehouse, or high-mix industrial operation, Akuros offers tailored solutions—combining automation, flexibility, and intelligence—to transform your warehouse into a modern, efficient, and profitable logistics hub.