🗣️ A Conversation That Started a Warehouse Revolution

Layla (Warehouse Operations Manager, Dubai Logistics Hub):

“Our warehouse is running out of space. We’re stacking pallets wherever there’s room, but our reach trucks can barely turn anymore. Expansion isn’t an option — land costs are too high.”

Omar (Supply Chain Consultant):

“That’s the classic symptom of a traditional wide-aisle setup. You’re losing up to 40% of your available space. You should look into Very Narrow Aisle racking — it doubles capacity without adding square footage.”

David (Supply Chain Solutions Buyer, Akuros):

“At Akuros, we’ve seen how integrating VNA systems into one-stop warehouse solutions can unlock up to 80% storage density, reduce accidents, and improve automation compatibility. It’s not just about racking — it’s a smarter way to design a warehouse ecosystem.”

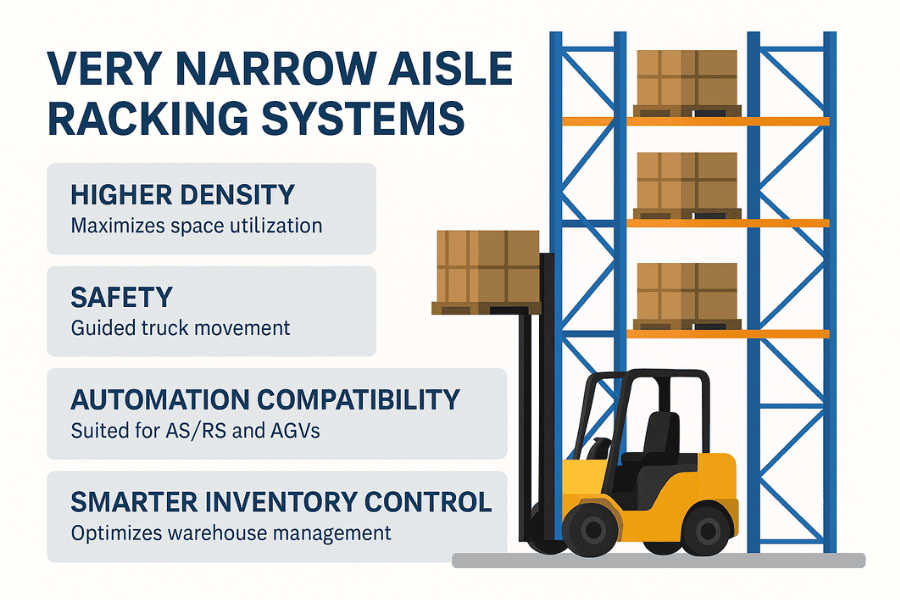

Very Narrow Aisle Racking Systems

What Makes Very Narrow Aisle Racking Different

1.1 Space Utilization and Design Efficiency

-

Reduces aisle width from 3.5m to as little as 1.6m — maximizing cubic volume.

-

Increases pallet density by up to 85% without facility expansion.

-

Designed for reach or turret trucks, allowing higher vertical storage (up to 17m).

1.2 Safety and Structural Integrity

-

Anti-sway bracing for tall racks in seismic zones.

-

Powder-coated steel for corrosion resistance in humid environments.

-

Floor-guided or wire-guided systems for precision truck movement.

1.3 Comparison Table: VNA vs Conventional Racking

| Caraterística | Estantes para corredores muito estreitos | Conventional Racking |

|---|---|---|

| Largura do corredor | 1.6 – 2.0 m | 3.0 – 3.5 m |

| Storage Density | 70–85% | 40–50% |

| Safety Level | High (guided) | Medium |

| Automation Compatibility | Excellent | Limitada |

| Installation Cost | Moderado | Lower short-term |

| Long-Term ROI | Elevado | Moderado |

Premium Engineering & Material Selection

2.1 Engineering Excellence

-

Manufactured from cold-rolled steel for consistent load-bearing performance.

-

Load capacity up to 1,500–2,000 kg per pallet position.

-

Integrated locking beams e boltless designs for faster assembly.

2.2 Coating & Finishing Technology

-

Epoxy powder coating resists scratches, rust, and moisture.

-

Available in anti-static and fire-resistant versions.

-

Laser-cut precision holes ensure perfect beam alignment.

2.3 Why Akuros Chooses These Systems

At Akuros, we evaluate VNA racking systems based on lifecycle value, adaptability, and compliance.

Our one-stop approach ensures each project combines:

-

Space optimization

-

Safety design

-

Inventory automation

See more about our approach: Soluções de Armazém Akuros One-Stop

Percepções de especialistas e dados científicos

Industry Trends:

“VNA systems are the foundation of next-generation warehouses. They bridge the gap between automation, sustainability, and efficiency.”

- Prof. Elena Rossi, Journal of Global Logistics, 2024

Scientific Data:

-

McKinsey 2024: VNA adoption boosts warehouse throughput by 28% compared to wide-aisle systems.

-

Fraunhofer Institute 2023: VNA-equipped warehouses report 30% fewer forklift accidents.

-

PwC 2024: 67% of Middle East and European buyers prefer one-stop VNA-based solutions due to compliance and scalability.

Estudo de caso (Akuros):

A logistics hub in Riyadh upgraded to a VNA layout integrated with Akuros’ one-stop warehouse system — achieving 35% higher storage density e 20% lower energy use through LED zoning and AI-powered forklift routing.

Real-World Applications & Customer Feedback

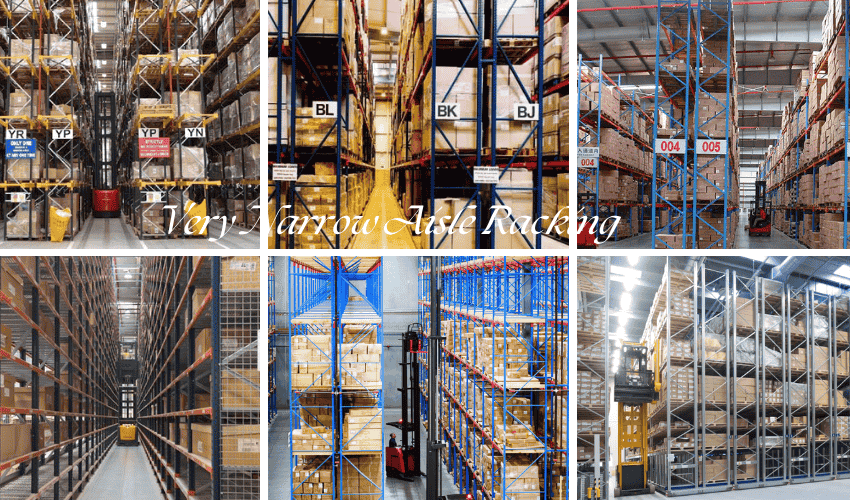

Case 1 — Dubai Free Zone:

A regional e-commerce client used VNA systems to manage seasonal inventory surges. Result: increased pallet count by 50% within the same area.

Case 2 — Saudi FMCG Warehouse:

Transitioning to guided VNA racks improved safety compliance with ISO 28000, reducing incident rates by 40%.

Case 3 — European Retail Exporter:

VNA integration cut loading/unloading time by 22% and improved order accuracy.

Customer Voices:

-

“Our warehouse finally feels organized, and productivity jumped instantly.” — Logistics Director, UAE

-

“The investment in narrow aisles paid off in under a year.” — Warehouse Planner, Turkey

Estantes para corredores muito estreitos

🧭 FAQ

1. What is a Very Narrow Aisle Racking System?

A Very Narrow Aisle (VNA) Racking System is a high-density storage design that minimizes aisle width to maximize warehouse capacity. It uses specialized forklifts and guidance systems to allow safe, precise pallet handling in tight spaces.

2. How does a Very Narrow Aisle Racking System improve warehouse efficiency?

By reducing aisle widths and increasing vertical storage, VNA systems can raise usable warehouse space by up to 85%. Combined with automation and guided movement, they improve picking speed, lower accidents, and reduce energy waste.

3. Is Very Narrow Aisle Racking compatible with warehouse automation?

Yes. VNA racking is ideal for AS/RS (Automated Storage & Retrieval Systems), AGVs (Automated Guided Vehicles)e RFID tracking. It enhances inventory visibility and accuracy in armazém único ecosystems.

4. What industries benefit most from VNA racking systems?

Sectors such as logistics, retail, automotive parts, FMCG, pharmaceuticals, and e-commerce gain the most, as they manage large SKU volumes within limited warehouse footprints.

5. Why are VNA systems essential for one-stop warehouse solutions?

They enable centralized design integration — combining racking, safety systems, and smart tracking into a single ecosystem. This reduces downtime, improves compliance, and extends rack lifespan, aligning perfectly with sustainable logistics goals.

📚 Referências

-

McKinsey & Company (2024). Supply Chain Optimization and Spatial Efficiency in Global Logistics.

-

Fraunhofer Institute (2023). Warehouse Safety and Automation Study.

-

PwC Research (2024). Smart Warehousing and Future Supply Chains Report.

-

Journal of Global Logistics (2024). Elena Rossi – Automation and Narrow Aisle Design in Modern Warehousing.

-

Fórum Económico Mundial (2024). Global Logistics Infrastructure Development Report.

-

ISO (2023). Warehouse Safety Standards ISO 15512 and ISO 28000.

-

Deloitte Insights (2024). Rethinking Storage Systems for Efficiency and ESG Alignment.

-

MIT Center for Transportation & Logistics (2023). Engineering Narrow Aisle Systems for Future-Ready Warehouses.

-

Gartner (2025). Automation and Robotics Trends in Global Warehousing.

-

Akuros Research Department (2025). Practical Implementation of Very Narrow Aisle Systems in One-Stop Warehouse Solutions.

In summary, VNA racking is more than metal and beams—it’s the backbone of a modern logistics strategy that values density, safety, and sustainability in equal measure. Companies that act early gain an enduring edge: lower operating costs, higher space utilization, and readiness for the next automation leap.