» D-Series Sideshifting Fork Positioner

Precision Load Handling for Demanding Industrial Applications

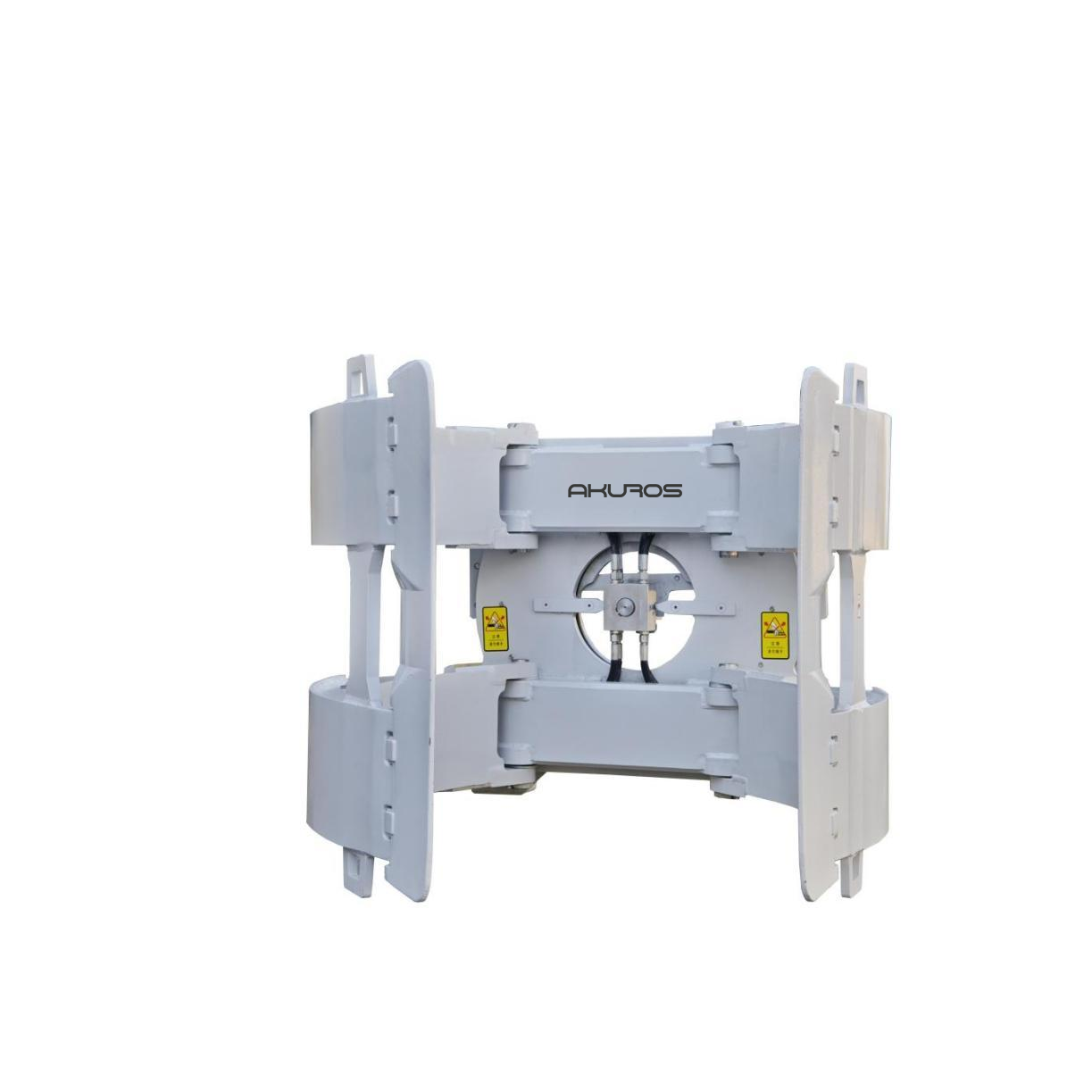

Visão geral do produto

O Akuros D-Series Posicionador de forquilha de mudança lateral is engineered for high-intensity material handling environments where load accuracy, lateral positioning efficiency, and structural reliability are critical. Designed with a robust frame architecture and independent fork positioning cylinders, the D-Series enables operators to adjust fork spacing and shift loads laterally without leaving the cab, significantly improving productivity and safety.

This attachment is especially suitable for logistics centers, manufacturing plants, cold storage facilities, and distribution warehouses handling variable pallet sizes and frequent load transitions.

Key Specifications & Functional Summary

| Category | Descrição |

|---|---|

| Product Type | Sideshifting Fork Positioner |

| Series | D-Series |

| Fork Adjustment | Independent hydraulic fork positioning |

| Sideshift Function | Integrated lateral sideshift |

| Mounting Class | ISO Class II / III / IV (customizable) |

| Sistema hidráulico | Dual-cylinder fork positioning + sideshift cylinder |

| Frame Design | Heavy-duty welded steel structure |

| Visibilidade | Optimized open-frame design |

| Compatibility | Standard counterbalance forklifts |

| Typical Applications | Warehousing, logistics, manufacturing, cold storage |

Structural Design Philosophy

The D-Series is developed around structural symmetry and load balance. Unlike basic fork positioners, the D-Series uses a reinforced backplate and precision-machined sliding profiles to ensure both forks move smoothly and remain parallel during operation.

The sideshift mechanism is fully integrated into the frame, allowing lateral load movement without compromising fork alignment or lifting capacity. This design reduces torsional stress on the carriage and improves overall attachment lifespan.

Key structural advantages include:

-

Reinforced upper and lower mounting hooks

-

Optimized load center distribution

-

Reduced bending moment during offset handling

-

Enhanced rigidity under continuous duty cycles

Hydraulic Precision & Control Stability

The D-Series employs independent hydraulic fork positioning, allowing precise adjustment to accommodate varying pallet widths. Hydraulic flow is evenly distributed to ensure synchronized movement and eliminate sudden fork acceleration.

The integrated sideshift function allows operators to fine-tune load positioning with millimeter-level accuracy, reducing the need for repeated vehicle repositioning and minimizing aisle congestion.

This results in:

-

Faster pallet engagement

-

Reduced pallet damage

-

Improved racking alignment

-

Lower operator fatigue

Operational Efficiency in Real-World Scenarios

In fast-paced logistics and distribution environments, the ability to reposition loads laterally and adjust fork spacing in seconds translates directly into higher throughput.

Typical operational benefits include:

-

Faster truck loading and unloading

-

Improved dock utilization

-

Reduced cycle time per pallet

-

Enhanced handling of non-standard pallet sizes

In cold storage and temperature-controlled warehouses, the D-Series performs reliably under low-temperature conditions, maintaining smooth fork movement and consistent hydraulic response.

Safety & Operator Confidence

Safety is built into every functional aspect of the D-Series. Controlled fork movement prevents sudden shifts that could destabilize loads, while improved visibility allows operators to maintain clear sightlines during pallet engagement.

Additional safety-related advantages include:

-

Reduced manual fork adjustment

-

Lower risk of load slippage

-

Improved load centering accuracy

-

Stable handling during sideshift operations

Maintenance & Long-Term Reliability

The D-Series is designed for low maintenance and long service life. Wear components are easily accessible, and the sliding surfaces are engineered to minimize friction and uneven wear.

Maintenance advantages include:

-

Reduced lubrication frequency

-

Easy access to hydraulic connections

-

Durable wear pads and guides

-

Lower total cost of ownership over time

Typical Industries & Applications

The Akuros D-Series Sideshifting Fork Positioner is widely used in:

-

Warehousing & distribution centers

-

Manufacturing facilities

-

Cold chain logistics

-

FMCG and retail logistics

-

Palletized goods handling

Its flexibility makes it an ideal solution for operations managing high SKU diversity and frequent pallet changes.

Perguntas frequentes (FAQ)

What is the main benefit of a sideshifting fork positioner?

A sideshifting fork positioner allows operators to adjust fork spacing and shift loads laterally without leaving the cab, improving productivity, accuracy, and safety.

Is the D-Series compatible with existing forklifts?

Yes. The D-Series is designed for standard ISO forklift carriages, subject to forklift capacity and hydraulic compatibility.

Does the sideshift function affect lifting capacity?

The attachment is engineered to maintain optimal load distribution. Actual capacity depends on forklift specifications and load center considerations.

Is the D-Series suitable for cold storage environments?

Yes. The robust mechanical design and reliable hydraulic performance make it suitable for low-temperature logistics operations.

How does the D-Series reduce pallet damage?

Precise fork positioning and controlled sideshift movement reduce misalignment and uneven force during pallet handling.