The Problem Every Warehouse Faces

“We’re out of space again,” sighed the warehouse operations director during a Monday meeting in Hamburg.

“Then stop expanding outward,” replied the systems engineer, unfolding a layout plan. “Start building smarter inside.”

That short exchange captures one of the defining challenges of Europe’s logistics sector: limited space, rising land costs, and ever-higher customer expectations. In 2025, warehouse operators aren’t looking for bigger facilities—they’re searching for denser, smarter, and safer ways to store more within the same footprint.

여기에서 Drive-in Racking Systems redefine the logistics equation. By integrating high-density storage design into 원스톱 창고 operations, companies are transforming their spatial limits into strategic advantages.

Drive-in Racking Systems

The Science Behind Drive-in Racking Efficiency

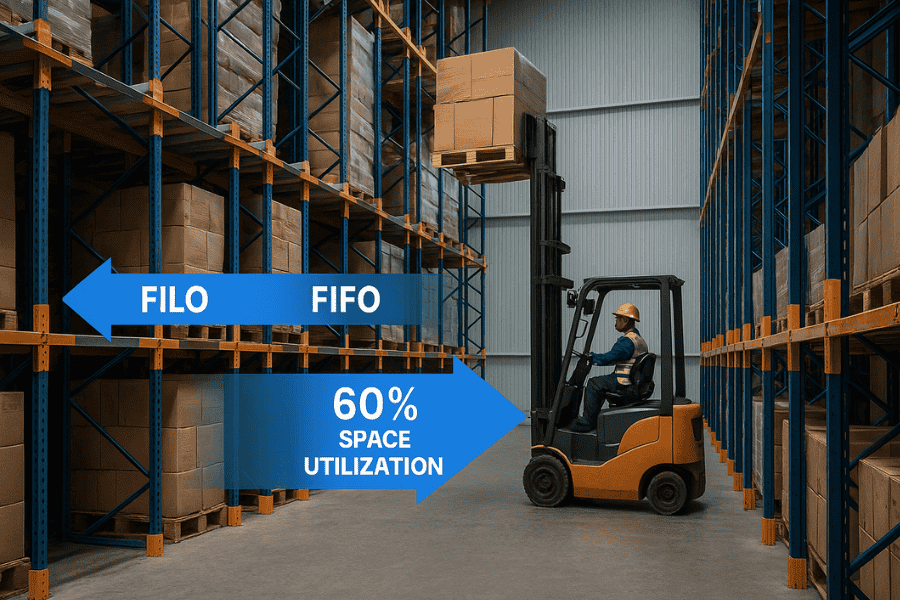

Unlike conventional selective pallet racks that require wide aisles, a 드라이브 인 랙 시스템 uses a “last-in, first-out” configuration that allows forklifts to drive directly into the rack structure. This reduces aisle space by up to 40%, instantly increasing the cubic utilization rate without expanding the building’s footprint.

Recent studies from the European Logistics & Automation Council (ELAC) show that facilities switching to drive-in systems gain:

-

Up to 60% more pallet positions per square meter

-

25% lower energy consumption due to reduced lighting and climate zones

-

30% faster retrieval speed when integrated with digital guidance

These numbers highlight why industries from food storage to e-commerce are rapidly adopting one-stop warehouse systems. Learn how different sectors benefit from integrated solutions in 원스톱 창고 서비스의 혜택을 가장 많이 받는 상위 산업군.

To understand why Drive-in Racking Systems are central to high-density warehousing, it helps to look at how the design functions inside a modern one-stop warehouse. The system’s efficiency lies in its controlled flow of movement—each lane acts as a dedicated storage tunnel, optimized for either FILO (First In, Last Out) or FIFO (First In, First Out) operations depending on product type and rotation frequency.Drive-in configurations are ideal for bulk or low-rotation goods—forklifts enter from one end, stacking multiple pallets deep within the same aisle. This reduces aisle requirements, maximizing cubic volume. Meanwhile, drive-through setups open lanes at both ends, enabling smoother turnover for perishable or fast-moving stock while maintaining density.The result is a space-efficient structure that balances load stability, accessibility, and safety. Compared with conventional selective pallet racks, drive-in systems can achieve up to 60% more storage density within the same footprint, especially in cold storage, bulk material, or manufacturing environments.

Design components include upright frames, guide rails, rollers, and reinforced beams, built for deep-lane forklift access and customizable bay configurations. When matched with precision-engineered forklifts and proper floor spacing, the system ensures reliable pallet handling, reduced collision risk, and faster throughput—all without sacrificing safety or structure integrity.

This integration makes the Drive-in Racking System not just a storage method but a cornerstone of one-stop warehouse optimization—where density, control, and workflow harmony coexist.

Engineering the Perfect Balance: Design, Materials, and Durability

The success of any 드라이브 인 랙 시스템 relies on material precision and structural alignment. While low-cost racks can deform under uneven loading, Akuros’ one-stop warehouse designs ensure structural symmetry and consistent performance across temperature and humidity variations.

Core engineering factors include:

-

High-tensile structural steel (S355 grade and above) with galvanized or epoxy coatings

-

Seismic-resistant joint assemblies tested under EN 15512 standards

-

Modular bay construction allowing customization for pallet depth and load profiles

This combination guarantees long-term durability—critical in European markets where maintenance costs can quickly exceed installation savings.

By integrating these features into its Drive-in Racking Systems, 아쿠로스 ensures every warehouse layout aligns mechanical strength with operational intelligence. Explore full system specifications at 드라이브 인 랙 시스템.

Powering the Flow: Forklift Energy and Motion

Even the most efficient rack is useless without an equally optimized movement system.

According to ESTA’s 2025 Mobility Report, more than 35% of warehouse inefficiency comes from uncoordinated equipment movement and low battery performance.

Modern one-stop facilities now integrate forklift energy solutions into their racking design, ensuring power availability, charging safety, and consistent runtime. For instance, lithium-ion forklift batteries reduce charging downtime by 60% and extend lifecycle performance by 35%.

For a deep dive into energy optimization, explore Forklift Battery Solutions—a core component of how Akuros keeps one-stop warehouses running continuously.

Ground-Level Movement: The Role of Pallet Trucks

While racking defines the warehouse skeleton, 팔레트 트럭 define its movement. They’re the muscle that carries the system’s heartbeat—fast, controlled, and safe.

European safety data from 2024 shows that optimized pallet truck pathways can cut accident risks by 27% and increase workflow efficiency by 19%.

By combining guided drive-in lanes with structured pallet truck zoning, one-stop warehouse operators achieve seamless material flow and reduced idle time. Learn how to refine your facility’s ground operations in 팔레트 트럭에 대해 알아야 할 모든 것.

Real-World Case Study: From Congested to Coordinated

In 2024, a mid-sized manufacturer in Belgium partnered with 아쿠로스 to retrofit its overfilled logistics center. Originally relying on selective pallet racks, the facility could only utilize 58% of available cubic space.

After installing a drive-in racking layout with integrated forklift battery and pallet truck systems, the results were clear:

-

Storage capacity increased by 63% without building expansion

-

Energy usage dropped by 22% due to reduced forklift travel distance

-

Safety incidents fell by 37%, verified by third-party inspection

Such outcomes underscore the philosophy behind one-stop warehouse design: optimization isn’t about size—it’s about synergy.

For more insights into integrated warehouse transformation, explore Akuros’ One-Stop Warehouse Solutions.

드라이브 인 랙 시스템

Expert Insights: Industry Voices on High-Density Warehousing

Dr. Elena Krauss, senior researcher at the European Warehouse Engineering Institute, explains:

“The value of drive-in systems lies not just in cubic utilization, but in their ability to integrate with automation, safety controls, and real-time data systems. That’s the real backbone of a one-stop warehouse.”

An ESTA 2025 report further confirms this, showing that multi-integrated warehouse networks reduce downtime by 23% compared to multi-vendor setups. Experts predict a strong shift toward unified warehouse ecosystems by 2030, driven by logistics consolidation and sustainability goals.

자주 묻는 질문

Q1: What is a Drive-in Racking System?

A1: It’s a high-density storage structure allowing forklifts to enter the rack lanes, ideal for uniform product storage and limited space environments.

Q2: How does a one-stop warehouse improve logistics performance?

A2: By integrating racking, energy, and equipment management systems under one provider, reducing operational friction and maintenance costs.

Q3: Can Drive-in Racking Systems work in cold storage?

A3: Yes, with appropriate anti-corrosion coatings and temperature-resistant joints, they perform reliably in -25°C environments.

Q4: How long does installation typically take?

A4: Depending on layout and bay depth, installation can take 3–6 weeks, with minimal disruption to ongoing operations.

Q5: What’s the ROI period for switching to high-density systems?

A5: Most facilities achieve return on investment within 18–24 months through improved space utilization and lower energy costs.

참조

-

European Logistics & Automation Council (2025). High-Density Storage Systems and Their Impact on Operational Efficiency.

-

ESTA Logistics Forum Report (2025). Warehouse Mobility and Energy Integration Trends.

-

European Warehouse Engineering Institute (2024). The Science of Structural Balance in Drive-in Racking Systems.

-

LogisticsIQ Research (2025). How Design Integration Enhances Warehouse Performance.

-

Global Supply Chain Benchmark Survey (2024). Comparative Analysis of Drive-in vs Selective Racking Systems.

-

EU Industrial Safety Commission (2024). Accident Reduction through Optimized Warehouse Layouts.

-

Smart Mobility Alliance (2025). Forklift Battery Innovations and Energy Efficiency in Logistics.

-

Cold Chain Europe (2024). Performance Evaluation of Drive-in Racks in Low-Temperature Storage Facilities.

-

Sustainable Infrastructure Journal (2025). Life-Cycle Durability of High-Tensile Steel in Industrial Applications.

-

Automation & Logistics Review (2025). The Rise of One-Stop Warehousing: Integrating Structure, Motion, and Intelligence.

Dr. Lars Hoffmann, a senior warehouse design consultant, summarizes it best:

“The future of warehousing lies in harmonized design—where structure, motion, and power exist as one system. It’s not about stacking more; it’s about thinking smarter.”

Incorporating these principles, Akuros continues to pioneer one-stop warehouse solutions that combine durability, mobility, and real-time intelligence. For operators aiming to upgrade capacity without expansion, the path forward is clear: invest not in more square meters, but in systems that make every cubic meter count.