内容

The Performance Features and Advantages of Pallet Trucks

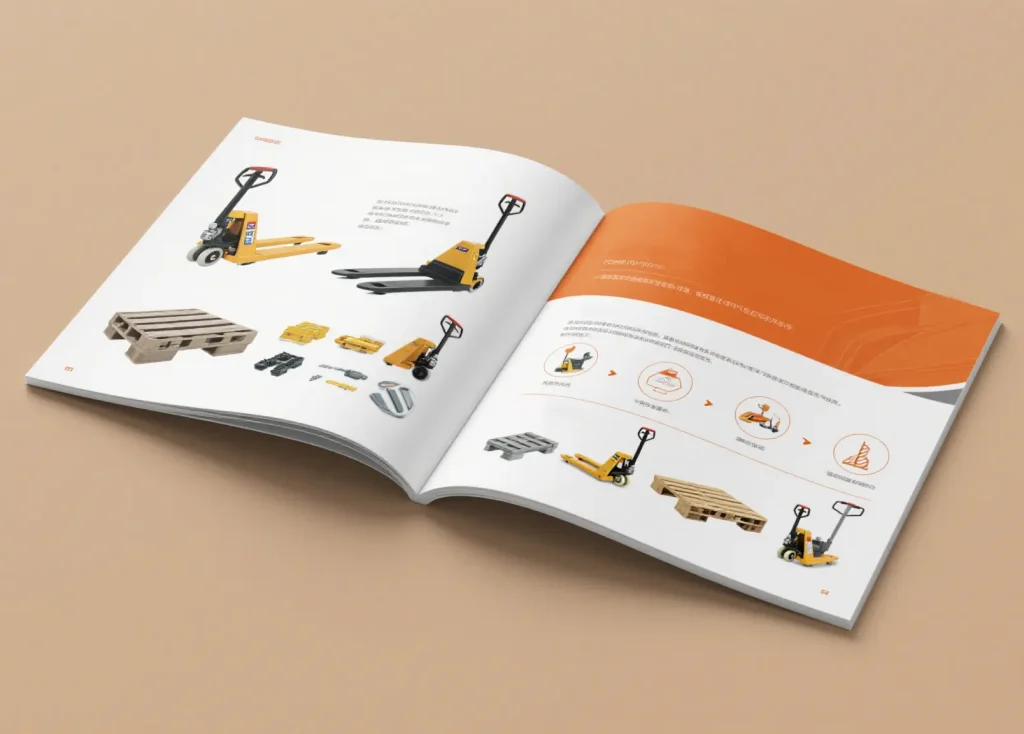

Pallet trucks, commonly used in material handling and warehouse logistics, are indispensable tools designed to move パレット商品 with minimal effort. These tools offer a range of performance features that enhance operational efficiency across diverse industries. One key feature is their 負荷容量, which enables them to handle substantial weights without compromising safety or ease of use. From light-duty to heavy-duty models, are engineered to adapt to varying logistical needs.

Another advantage lies in their maneuverability, allowing operators to navigate narrow aisles and tight corners—an essential requirement in space-constrained warehouse environments. Furthermore, advancements in handle design provide ergonomic benefits, reducing fatigue during prolonged use. Whether it’s a manual or electric model, the structure ensures optimal operator safety through stable movement and reliable control systems.

The inclusion of quality load wheels contributes to smooth rolling over various floor surfaces, thereby improving handling even in challenging conditions. Additionally, many modern パレットトラック come with built-in braking mechanisms, adding another layer of safety, especially when working on inclines or slippery areas. These combined features significantly extend the operational lifespan of the equipment while minimizing maintenance demands.

スタンドアップパレットトラック

Application Strategies of Pallet Trucks in Different Warehouse Layouts

In today’s diverse warehouse environments, deploying パレットトラック effectively requires understanding the unique layout and logistical demands of each facility. Open floor warehouses benefit from high-capacity, long fork pallet trucks that can transport multiple パレット商品 simultaneously. In contrast, high-density storage layouts—common in retail and e-commerce fulfillment centers—require compact models with enhanced maneuverability to operate within limited aisle widths.

Strategic application of パレットトラック also involves matching the 負荷容量 to the type of goods being handled. For example, a facility dealing with fragile items may prefer models with smoother load wheels to minimize shock during transit. Meanwhile, warehouses focused on bulk materials might prioritize trucks with reinforced forks and greater weight tolerance.

Beyond physical layouts, the workflow pattern also influences the choice and use of パレットトラック. Cross-docking operations benefit from electric models for quick transfers, while manual models are sufficient in facilities with slower turnover rates. Overall, tailored strategies enhance the role of パレットトラック in optimizing space utilization and improving throughput.

Operational Techniques and Safety Standards for Pallet Trucks

Effective use of パレットトラック goes hand in hand with adherence to proven operational techniques and stringent safety standards. Before operation, users should always inspect the unit for wear or damage, focusing on critical components like load wheels, forks, and the braking mechanism. Ensuring these parts are in working order prevents accidents and maintains the truck’s operational lifespan.

Training personnel in proper handling techniques is vital. For example, operators should avoid overloading beyond the rated 負荷容量, as this can destabilize the equipment. Proper handle design usage—like using both hands to push rather than pull—also enhances control and reduces strain-related injuries. Moreover, maintaining a clear path and using the correct lifting posture significantly improves operator safety.

Workplace policies should include speed limits, especially for electric models, and enforce right-of-way rules to prevent collisions. Additionally, periodic safety audits can identify unsafe practices and equipment defects, ensuring compliance with occupational safety guidelines. Through disciplined practice and routine checks, the use of パレットトラック can be both safe and efficient.

パレットトラック

Comparison Between Electric and Manual Pallet Trucks

Choosing between electric and manual パレットトラック depends on several operational variables. Manual パレットトラック are typically more economical and ideal for light to moderate-duty applications. They are easy to maintain, require no charging infrastructure, and are best suited for small-scale warehouses or intermittent use.

On the other hand, electric パレットトラック offer significant advantages for high-volume and large-scale operations. Their powered lift and drive systems reduce physical strain on operators, thereby improving operator safety and efficiency. Features such as powered braking mechanisms and responsive throttle control enhance maneuverability, making them ideal for fast-paced environments.

While electric models typically involve higher upfront costs and ongoing battery maintenance, they excel in environments where continuous movement of パレット商品 is necessary. Their extended operational lifespan, combined with enhanced ergonomics and load-handling capabilities, often justify the investment. Ultimately, understanding the specific demands of the warehouse helps in selecting the right type of パレットトラック for optimal results.

Maintenance and Care Essentials for Pallet Trucks

To ensure the longevity and performance of パレットトラック, regular maintenance and proper care are essential. Routine inspections should include checks on load wheels, forks, hydraulic systems, and the handle design for wear or misalignment. Lubrication of moving parts is also critical to prevent rust and ensure smooth operation.

Battery care is particularly important for electric models. Operators must ensure that batteries are charged correctly and kept clean to prevent power loss and corrosion. Similarly, the braking mechanism must be tested frequently to guarantee reliable stopping power.

Storage plays a significant role in prolonging the operational lifespan の パレットトラック. They should be stored indoors on level surfaces to avoid damage to the wheels or frame. Training maintenance staff to recognize early signs of mechanical failure also helps prevent major breakdowns. A well-maintained パレットトラック not only ensures operator safety but also supports consistent warehouse productivity.

カスタマイズ可能なパレットトラック

Market Development Trends and Innovations in Pallet Trucks

について パレットトラック market is evolving rapidly, driven by the demand for automation, safety, and efficiency. One of the major trends is the integration of smart sensors and telematics into electric models. These innovations allow for real-time tracking, automated fault detection, and even predictive maintenance, significantly improving the operational lifespan and efficiency of the equipment.

Another emerging trend is the development of eco-friendly electric パレットトラック with lithium-ion batteries, offering faster charging, longer cycles, and reduced environmental impact. Additionally, enhanced handle designs now include digital controls and anti-slip surfaces for better operator safety.

Innovative load wheels made from advanced polymers are also gaining popularity due to their noise reduction and durability on various surfaces. Furthermore, modular design approaches are making it easier for companies to customize パレットトラック for specific needs, whether in cold storage, hazardous materials, or automated conveyor systems.

The Impact of Pallet Trucks on Enhancing Warehouse Efficiency

Pallet trucks play a pivotal role in enhancing warehouse efficiency by reducing manual labor, accelerating material handling, and ensuring the smooth transport of パレット商品. By streamlining workflows and minimizing bottlenecks, these tools contribute to faster order fulfillment and better inventory management.

電気 パレットトラック, in particular, boost productivity by enabling operators to move heavier loads with less effort. This not only reduces downtime but also minimizes worker fatigue, promoting higher morale and lower injury rates. In high-throughput environments, improved maneuverability and reliable braking mechanisms ensure seamless operation across multiple shifts.

Furthermore, with smart scheduling and layout planning, パレットトラック can be integrated into automated systems, offering continuous movement and real-time data tracking. By enhancing material flow and maximizing space, パレットトラック ultimately support lean warehouse practices and long-term business growth.

The Growing Role of Pallet Trucks in Modern Logistics

The importance of パレットトラック in contemporary warehouse logistics cannot be overstated. As global supply chains become more complex, the need for efficient, adaptable, and safe material handling equipment increases. From enhancing operator safety with ergonomic handle designs to extending service life through durable load wheels, every innovation reinforces the critical role these tools play.

Moreover, the continuous development in electric variants and automation technologies further cements their position in modern logistics infrastructure. Whether used in retail, manufacturing, food storage, or freight forwarding, パレットトラック prove indispensable for optimizing warehouse operations.

The Pallet Truck Operator’s Guide

In the fast-paced world of warehouse logistics, the integration of パレットトラック has brought transformative benefits to the handling of パレット商品. Their ability to support heavy load capacities, provide unmatched maneuverability, and ensure operator safety has made them a cornerstone of efficient material transport systems. Whether choosing between manual and electric models, or implementing tailored strategies across varied warehouse layouts, the value of a well-maintained パレットトラック is undeniable.

As technological advancements continue to shape the material handling industry, innovations in handle design, smart features, and eco-conscious power systems promise to redefine what パレットトラック can achieve. Businesses that invest in the proper use, maintenance, and integration of these tools will not only benefit from enhanced productivity but will also future-proof their operations in a rapidly evolving marketplace.

With the right strategy and equipment, パレットトラック will continue to drive operational excellence—helping businesses move faster, safer, and more efficiently than ever before.For example: “Want to learn more about purchasing パレットトラック?今すぐお問い合わせください。