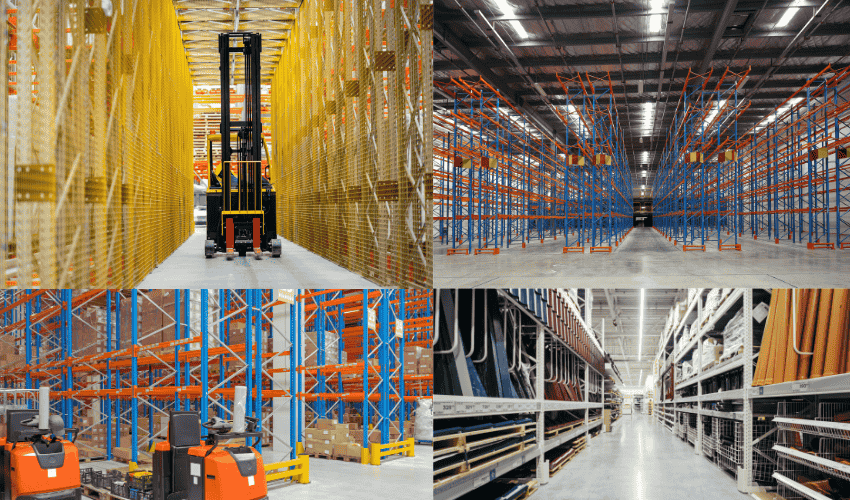

Top 7 Advantages of Using Narrow Aisle Racking in Space-Constrained Facilities

Modern warehouses face increasing pressure to maximize storage within limited footprints, especially as urban logistics hubs and high-volume fulfillment centers expand. For facilities dealing with space constraints, Rayonnage pour allées étroites systems present a highly efficient, scalable, and safe solution.

In this article, we explore the top 7 advantages of adopting Rayonnage pour allées étroites for your operations and how it transforms vertical and horizontal storage capacity without compromising accessibility or safety.

Narrow aisle racking

Contenu

- 1 Space Optimization Without Expansion

- 1.1 Improved Inventory Access and Accuracy

- 1.1.1 Cost-Efficiency Over Time

- 1.1.2 Enhanced Vertical Storage Utilization

- 1.1.3 Seamless Integration with Automation

- 1.1.4 Better Safety in Tight Spaces

- 1.1.5 Future-Proof Scalability

- 1.1.6 With retail and e-commerce constantly evolving, warehouses need flexible infrastructure. Narrow Aisle Racking offers just that—flexibility, resilience, and long-term scalability.

- 1.1.7 Real-World Success Case: Urban Logistics Center in Singapore

- 1.1.8 Frequently Asked Questions (FAQ)

- 1.1.9 Why Narrow Aisle Racking Is the Smarter Choice

- 1.1 Improved Inventory Access and Accuracy

Space Optimization Without Expansion

The most prominent benefit of Rayonnage pour allées étroites is its ability to maximize storage capacity within the existing warehouse footprint. Traditional selective racking systems typically require wider aisles (up to 12 feet) to accommodate standard forklifts. In contrast, narrow aisle solutions reduce aisle width to approximately 6 feet, instantly increasing the number of pallet positions.

This spatial efficiency allows businesses to avoid costly expansions or off-site warehousing. Instead of building out, Rayonnage pour allées étroites enables them to build up, leveraging the full height of the facility.

Improved Inventory Access and Accuracy

Despite their reduced aisle width, Narrow Aisle Racking systems maintain excellent selectivity. Each pallet remains directly accessible, ensuring that order fulfillment and inventory management can continue without disruption.

When paired with specialized equipment such as Very Narrow Aisle (VNA) trucks or articulated forklifts, operators can navigate tight aisles and access higher racks with precision. This leads to:

-

Faster picking speeds

-

Fewer picking errors

-

Enhanced cycle counting and real-time inventory tracking

Cost-Efficiency Over Time

While the initial investment in Rayonnage pour allées étroites and compatible handling equipment may be higher, the long-term ROI is substantial. Businesses benefit from:

-

Delayed capital expenditure on expansion

-

Increased inventory storage per square foot

-

Reduced land and utility costs

When analyzed over a five-year period, these systems often outperform traditional storage models in cost-effectiveness and throughput efficiency.

Enhanced Vertical Storage Utilization

By integrating taller racking frames—often exceeding 10 meters—Rayonnage pour allées étroites encourages warehouses to optimize their vertical space. This vertical orientation:

-

Accommodates seasonal or high-volume inventory

-

Allows for efficient zoning by SKU velocity

-

Reduces floor congestion during peak times

Modern warehouses often overlook their vertical potential. Rayonnage pour allées étroites makes it practical and safe to operate in tall storage environments.

Seamless Integration with Automation

| Automation Integration in Narrow Aisle Racking | Description |

|---|---|

| Pallet Shuttle Systems | Automatically transport pallets within racks, reducing forklift dependency. |

| Automated Storage and Retrieval Systems (AS/RS) | Enable high-density storage and rapid item retrieval with minimal labor input. |

| Smart Sensors & IoT Integration | Real-time tracking of inventory, equipment status, and environmental conditions. |

Better Safety in Tight Spaces

It’s a common misconception that narrow aisles are more dangerous. In reality, Narrow Aisle Racking systems are designed with safety in mind. When used with VNA trucks or turret trucks equipped with safety sensors, the following is ensured:

-

Collision avoidance via onboard cameras and proximity sensors

-

Ergonomic operator cabins for maximum visibility

-

Guidance rails or wire guidance systems for precise movement

These systems also undergo strict compliance with ISO and OSHA safety standards, giving warehouse managers peace of mind.

Future-Proof Scalability

As your operations grow, your racking system should grow with you. Rayonnage pour allées étroites is modular and highly adaptable, allowing for:

-

Easy reconfiguration to add new aisles

-

Vertical extensions without dismantling the system

-

Integration with mezzanine floors or second-level picking

With retail and e-commerce constantly evolving, warehouses need flexible infrastructure. Rayonnage pour allées étroites offers just that—flexibility, resilience, and long-term scalability.

Narrow aisle racking suitable for warehouses

Real-World Success Case: Urban Logistics Center in Singapore

A leading logistics company in Singapore recently upgraded their outdated racking system to Rayonnage pour allées étroites across a 6,000 sqm facility in Changi. The result:

-

38% increase in pallet positions

-

25% reduction in retrieval times

-

0 reported forklift incidents post-upgrade

The change enabled the company to accommodate growing e-commerce fulfillment demand without leasing additional property.

Frequently Asked Questions (FAQ)

What type of forklifts are required for Narrow Aisle Racking?

Specialized forklifts like turret trucks, articulated forklifts, or VNA trucks are used for safe and efficient navigation.

Can I convert an existing warehouse to a Narrow Aisle system?

Yes. Many warehouses retrofit existing layouts to accommodate Rayonnage pour allées étroites, especially when expanding vertically.

Is Narrow Aisle Racking suitable for cold storage?

Absolutely. The high-density layout makes it ideal for cold storage where energy efficiency and floor space are premium.

What are the safety considerations?

Systems must include aisle guidance, operator training, and compliance with local and international safety standards.

How does this system support inventory management?

Rayonnage pour allées étroites supports accurate inventory control when integrated with a WMS and real-time tracking systems.

Space-saving Narrow Aisle Racking

Why Narrow Aisle Racking Is the Smarter Choice

Space is a premium resource in today’s warehousing. Rather than settling for traditional, space-wasting solutions, businesses should embrace Rayonnage pour allées étroites as a future-ready alternative. It not only optimizes every inch of your warehouse but also supports the demands of automation, high throughput, and flexible growth.

From improved accessibility and better safety to cost-efficiency and automation compatibility, Rayonnage pour allées étroites is truly the intelligent choice for space-constrained environments.

Partager :