Labor Cost, Safety & Automation Readiness

Cold storage warehouses in North America face unique pressures driven by high labor costs, strict safety standards, and rapid automation adoption. This article explains how cold storage facilities in the U.S. and Canada should be designed and equipped to remain competitive—balancing compliance, throughput, and long-term automation readiness.

1. Why North America Cold Storage Requires a Different Approach

Cold storage design principles that work in Asia or emerging markets often under perform in North America. The reasons are structural rather than technical:

-

Labor costs are significantly higher and less flexible

-

Worker safety regulations are strictly enforced

-

Automation adoption is accelerating across cold chain logistics

-

Downtime has a direct and measurable financial impact

In this environment, operational stability and labor efficiency matter more than maximum density. Facilities designed without these priorities quickly lose competitiveness.

This is why North America projects must be planned within an integrated solution d'entrepôt framework rather than a low-CAPEX, equipment-first mindset.

2. North America Cold Storage Challenges — Overview Table

2. North America Cold Storage Challenges — Overview Table

Before examining system choices in detail, the table below summarizes the most common challenges faced by North American cold storage operators and the corresponding design priorities.

📊 North America Cold Storage Challenges & Design Priorities

| Regional Challenge | Operational Impact | Design Priority |

|---|---|---|

| High labor cost | Margin pressure | Labor efficiency |

| Strict safety standards | Compliance risk | Stable equipment & layout |

| Automation acceleration | Competitive gap | Automation-ready design |

| Workforce shortage | Throughput risk | Reduced manual dependency |

| Energy cost volatility | OPEX uncertainty | Efficient systems |

In North America, labor and safety considerations often outweigh pure storage density.

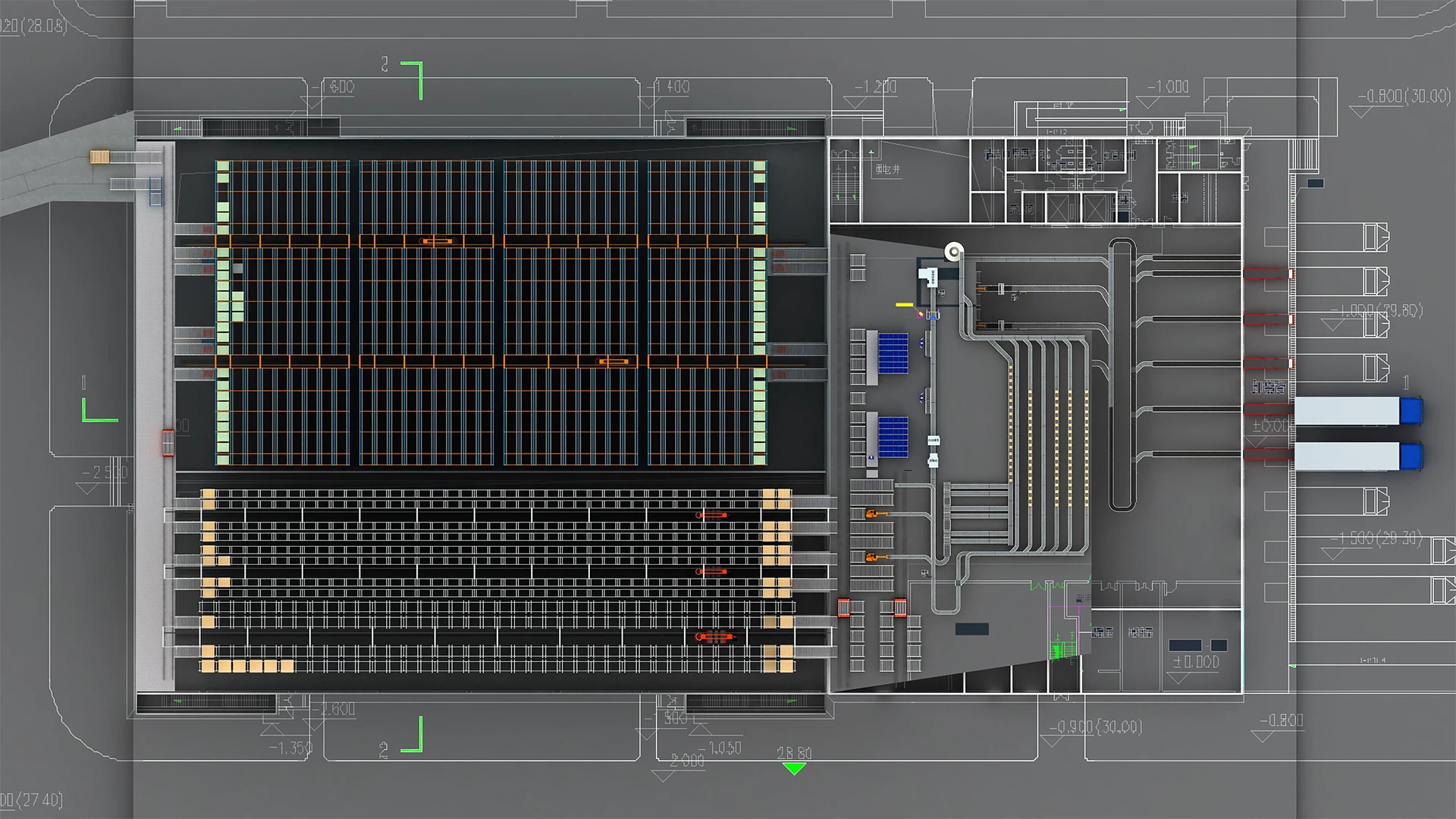

3. Layout Design Focused on Safety and Productivity

North American cold storage layouts emphasize predictability and safety. Wide, clearly defined traffic lanes, dedicated pedestrian zones, and consistent material flow are preferred over highly compact designs that increase risk.

Layouts should minimize:

-

Forklift–pedestrian interaction

-

Blind spots at aisle intersections

-

Complex maneuvers in frozen zones

Designing layout as part of a solution d'entrepôt ensures compliance with OSHA-aligned safety expectations while maintaining throughput.

4. Racking Systems Used in North America Cold Storage

Racking selection in North America reflects a balance between density and operational clarity.

-

Double deep racking systems are commonly adopted for frozen food and retail distribution, offering higher density without sacrificing access.

-

Very narrow aisle racking systems are increasingly popular in facilities preparing for automation and high SKU diversity.

Tandis que drive-in racking systems are still used for bulk frozen products, their adoption is more selective due to safety and flexibility concerns.

Rayonnage à double profondeur

5. Forklifts and Equipment Selection Under North America Standards

Forklifts in North America cold storage warehouses must meet both performance and safety expectations. Reliability is critical because labor downtime translates directly into lost revenue.

Facilities typically rely on:

-

Cold-adapted electric forklifts for indoor operations

-

Reach trucks for high-bay selective and double deep racking

-

Order pickers in high-frequency picking environments

Equipment that reduces operator fatigue and maintains stable performance at -25°C delivers measurable ROI in North American operations.

6. Automation Adoption in North America Cold Storage

North America leads global cold storage automation adoption, driven by labor scarcity and rising wage pressure.

Facilities increasingly deploy Systèmes AGV for repetitive pallet transport, especially when integrated into broader automated warehouse solutions. Automation is typically introduced in phases, starting with stable, low-variability tasks.

However, successful projects preserve manual flexibility for exception handling and seasonal volume spikes.

7. Energy Systems and Operating Cost Control

7. Energy Systems and Operating Cost Control

Energy costs in North America are volatile and region-dependent. Cold storage facilities must optimize both refrigeration and handling equipment efficiency.

Cold-rated forklift battery systems support longer shifts and reduce charging frequency, while efficient traction solutions minimize energy loss on frozen floors.

Energy-aware equipment selection contributes directly to lower total cost of ownership.

8. Common Mistakes in North America Cold Storage Projects

Typical pitfalls include:

-

Importing low-density or high-density layouts without local adaptation

-

Underestimating labor and safety compliance costs

-

Delaying automation planning until after commissioning

-

Selecting equipment based solely on upfront price

In North America, these mistakes often surface quickly through labor inefficiency and compliance pressure.

9. How Successful North America Cold Storage Facilities Are Designed

High-performing facilities share common traits:

-

Safety-first layout design

-

Equipment selected for uptime and ergonomics

-

Automation integrated strategically, not aggressively

-

Lifecycle cost prioritized over CAPEX minimization

These outcomes are best achieved through an end-to-end warehouse solution rather than fragmented decision-making.

10. Google Popular Topics (Contextual Answers)

Why is labor efficiency critical in North America cold storage?

Because labor costs are high and workforce availability is limited.

Which racking systems are common in North America cold storage?

Double deep and VNA racking are widely used due to safety and flexibility.

Is automation necessary in North America cold storage?

Not mandatory, but increasingly important to remain competitive.

What forklifts are preferred in North America cold storage?

Electric forklifts engineered for low-temperature, indoor operation.

How can North America cold storage reduce operating cost?

By optimizing layout, reducing labor dependency, and planning automation early.