In the ever-evolving world of warehousing, maximizing space and improving operational efficiency have become top priorities for logistics managers. One of the most transformative systems helping modern warehouses meet these goals is the Rayonnage à allées très étroites (VNA) solution.

Designed to take full advantage of vertical space and streamline material handling processes, VNA systems are the answer for companies seeking to boost storage capacity without expanding their facility footprint.

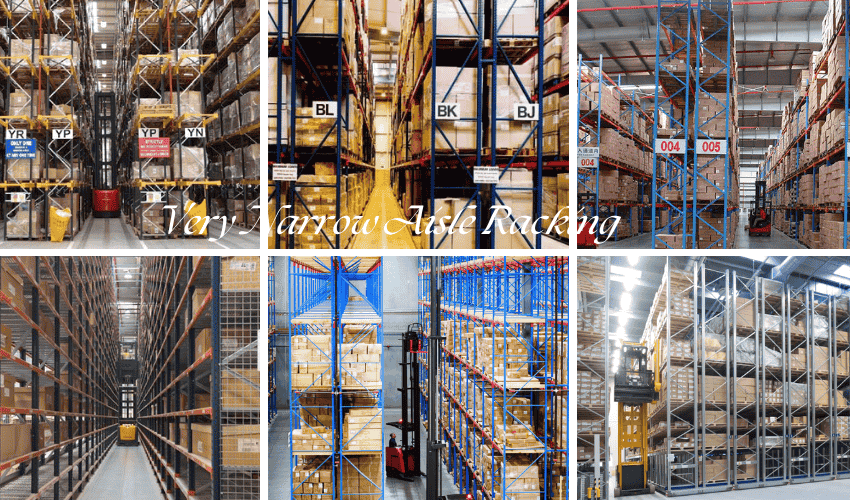

Rayonnage à allées très étroites

Contenu

An Introduction to Very Narrow Aisle Racking Systems

Rayonnage à allées très étroites is a high-density storage solution that features significantly tighter aisle widths—typically between 1.5 to 2 meters—compared to conventional pallet racking systems. This compact configuration allows for an increase in pallet positions by up to 60%, optimizing every cubic meter of warehouse space. The system is designed to be used in conjunction with specialized equipment such as turret trucks or articulated forklifts that can navigate tight spaces with precision.

Unlike standard racking that leaves broad paths for conventional forklifts, VNA racking systems reduce aisle width to the minimum required for guided handling equipment. This results in a higher density of pallet locations while preserving full access to each pallet, supporting both flexibility and inventory visibility.

How Does Very Narrow Aisle Racking Work?

The concept behind Rayonnage à allées très étroites is simple: by narrowing the space between racks, more storage can be fitted within the same warehouse footprint. However, the implementation requires thoughtful planning and equipment adaptation. VNA forklifts are equipped with swivel heads or extendable forks that allow them to operate in tight aisles without turning.

These forklifts are often guided by floor-mounted rails or wire-guidance systems, ensuring accurate movement and minimizing the risk of collision with the racking structure.

The racks themselves are usually adjustable to accommodate different pallet sizes and load types. Beam levels can be set to optimize vertical space based on product height, further enhancing storage efficiency.

Key Advantages of Very Narrow Aisle Racking

-

Maximized Storage Capacity

One of the main reasons companies invest in Rayonnage à allées très étroites is to make the most of their available warehouse space. With narrower aisles and taller rack configurations, warehouses can increase storage capacity by up to 50%–60%. -

Improved Inventory Access

Unlike drive-in or block stacking systems, VNA racking maintains 100% selectivity. Each pallet is accessible at any time, making it ideal for warehouses handling a diverse range of SKUs or needing real-time inventory control. -

Enhanced Picking Efficiency

With the help of guided forklift systems, warehouse staff can navigate the racks faster and more safely. Picking times are reduced, especially in operations where high-volume picking is essential. -

Higher Safety Standards

Many VNA systems incorporate electronic or mechanical guidance to ensure the safe movement of forklifts within narrow aisles. This reduces the likelihood of rack damage or product accidents, contributing to a safer working environment. -

Cost-Effective Expansion

Expanding a facility’s storage capabilities without constructing a new building is a major advantage. Rayonnage à allées très étroites allows businesses to grow within their current warehouse, deferring or avoiding costly expansions.

Applications dans tous les secteurs d'activité

| Industry | Application of Very Narrow Aisle Racking |

|---|---|

| Retail & E-commerce | Ideal for managing high SKU counts and enabling fast picking in fast-paced environments. |

| Produits pharmaceutiques | Supports controlled environments with organized, high-density storage and quick access to vital inventory. |

| Automobile | Efficiently stores spare parts and raw materials while maintaining selectivity and high storage density. |

| Alimentation et boissons | Facilitates FIFO inventory management, essential for handling products with strict expiration dates. |

Integration with Warehouse Technology

To further enhance efficiency, VNA systems are often integrated with warehouse management systems (WMS), automated picking technologies, and real-time inventory tracking. RFID and barcode scanning systems work seamlessly with VNA forklifts to ensure accurate stock movement and inventory control.

Modern VNA trucks can also be equipped with cameras and sensors to assist with pallet placement and retrieval at high elevations. These tools not only improve productivity but also reduce the learning curve for new operators.

- Design Considerations Before Implementation

Before switching to Rayonnage à allées très étroites, warehouses must evaluate several key factors:

-

Floor flatness and load-bearing strength

Uneven floors can compromise the operation of VNA-guided trucks. Concrete reinforcement may be necessary. -

Height limitations

The racking system should align with building height restrictions and comply with fire safety regulations, including sprinkler clearance. -

Forklift compatibility

Standard forklifts are not suitable for VNA environments. Facilities must invest in compatible VNA trucks or turret trucks. -

Operator training

Specialized handling equipment requires operator certification and training for safe and efficient use.

One-stop warehouse

Maintenance and Safety Practices

Maintaining Rayonnage à allées très étroites involves regular inspections to check for:

-

Rack alignment and stability

-

Damage to uprights or beams

-

Proper functioning of guidance systems

-

Clearance between pallets and racking components

Additionally, employee safety protocols—like speed limits within aisles and designated pedestrian pathways—should be reinforced to prevent accidents in the confined aisle spaces.

Comparing Very Narrow Aisle with Other Systems

| Fonctionnalité | VNA Racking | Selective Pallet Racking | Drive-in Racking |

|---|---|---|---|

| Aisle Width | 1.5–2m | 3–4m | 2.5–3m |

| Storage Density | High | Medium | Very High |

| Equipment Required | VNA Forklift | Standard Forklift | Standard Forklift |

| Selectivity | 100% | 100% | Limited |

| Ideal Use Case | High SKU / Medium Turnover | General Purpose | High Volume / Low SKU |

Future Trends in Narrow Aisle Storage

As automation becomes increasingly central in warehouse management, the next evolution of Rayonnage à allées très étroites includes full integration with automated guided vehicles (AGVs), robotic shuttle systems, and AI-based inventory management. These technologies will push VNA systems beyond traditional logistics into the realm of smart warehousing.

Companies are also exploring hybrid models where VNA is combined with mezzanine floors or multi-level picking platforms, further enhancing the vertical optimization of storage.

Analyze solutions for very narrow aisle racks

Rayonnage à allées très étroites is a powerful tool for any warehouse seeking to improve space utilization, safety, and operational efficiency. It offers a future-ready solution for logistics operations that must adapt to higher volumes and faster service expectations without sacrificing order accuracy or warehouse safety.

By narrowing the aisles and raising the racks—both figuratively and literally—VNA racking systems allow companies to rise to new heights in storage efficiency. Whether you’re dealing with limited warehouse space, rising rental costs, or growing SKU counts, this system offers a compelling return on investment with long-term operational advantages.

Nouvelles précédentes

Top 5 Benefits of Using a Drive-in Racking Syst...Nouvelles suivantes

Innovative Shelf Rack System for Every Industry...Partager :