- Trustpilot

Drive-in Racking Hub

Capabilities of Akuros Drive-in Racking

High-density storage

Streamlined Order Picking

Versatile Inventory Management

Safety and Stability Assurance

Contactez-nous pour des solutions personnalisées

- Fit your specific needs with our tailored solutions.

- Rigorously tested for reliability in various conditions.

- Manufacturer-direct, flexible options to suit your budget.

- Full maintenance and service to ensure long-term performance.

Envoyez vos besoins spécifiques

Du concept au fonctionnement à haut rendement

Évaluation des besoins

Analyser les besoins de l'entrepôt et les objectifs opérationnels.

Design conceptuel

Développer des solutions innovantes pour relever les défis des entrepôts modernes.

Prototypage

Créer et tester des prototypes pour valider les fonctionnalités.

Commentaires des utilisateurs

Refine designs based on user input and ergonomic testing.

Validation finale

Effectuer des essais en conditions réelles pour garantir la fiabilité.

Déploiement

Fournir une assistance à l'installation et une formation personnalisée.

Une qualité à laquelle vous pouvez faire confiance

Durabilité

Safety Long

Service Life

Industries spécialisées

Alimentation et boissons

Commerce électronique

Third-party Logistics (3PL)

Automotive Aftermarket

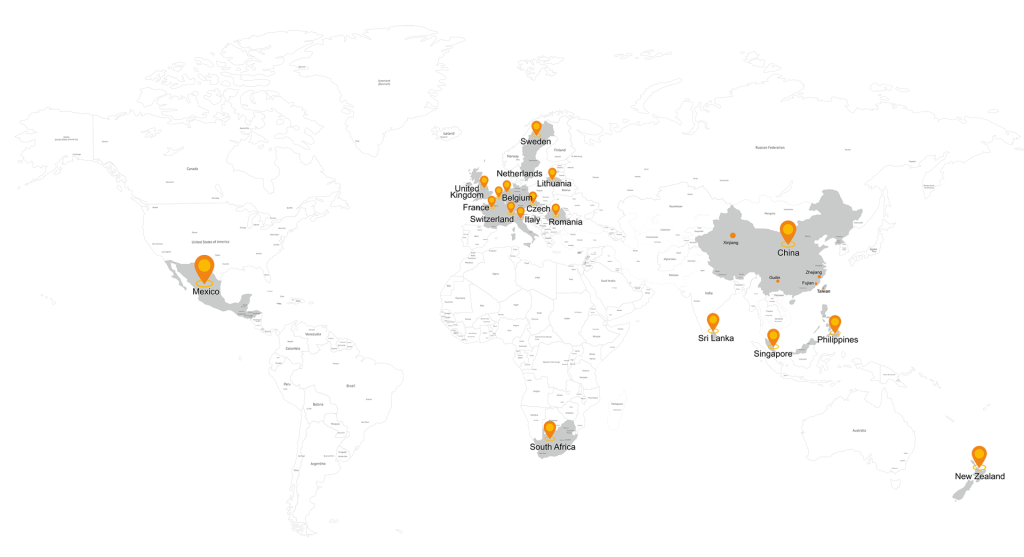

Portée du marché mondial de l'Akuros

Avantages de l'Akuros

Des partenariats stratégiques pour des solutions améliorées

| Produit | Spécifications | Application |

|---|---|---|

| Électrique | 1.5T, 3m Lift | Entrepôt |

| IC | 3T, 4.5m Lift | Logistique |

| Atteindre | 1T, 5m Lift | Vente au détail |

| Type | Capacité | Adapté |

|---|---|---|

| Acide de plomb | 80V/200Ah | Chariots élévateurs 1-3T |

| Lithium | 48V/400Ah | Chariots élévateurs 1-2T |

| NiMH | 72V/150Ah | Chariots élévateurs 1-2T |

| Type | Taille | Surface |

|---|---|---|

| Solide | 28×9-15 | Rugueux |

| Pneumatique | 23×8-12 | Lisse |

| Polyuréthane | 35×12-19 | Mixte |

| Pièce jointe | Adapté | Fonction |

|---|---|---|

| Déplacement latéral | 1-3T | Flexibilité |

| Rotateur | 2-5T | Allées étroites |

| Contrepoids | Tous | Stabilité |

| Equipement | Fonction | Cas d'utilisation |

|---|---|---|

| Poteau de pare-chocs | Collision | Entrepôt |

| Ceinture de sécurité | Opérateur | Tous les chariots élévateurs |

| Miroir | Visibilité | Tous les chariots élévateurs |

Based on 632 reviews

- Trustpilot

Amélioration de la productivité des entrepôts

Rationalisation des opérations d'entreposage

Cost-Efficient Warehouse Solutions

Drive-in Racking Operator's Guide

Ressources d'apprentissage et de soutien

Guides de démarrage

- Installation Best Practices

- Initial System Configuration

- Basic Operation Procedures

Manuels opérationnels

- Daily Operation Guidelines

- Load Handling Techniques

- Equipment Maintenance Schedule

Conseils de base pour la configuration des racks

- Maximizing Storage Density

- Aisle Design Considerations

- Product Segregation Strategies

Précautions de sécurité pendant l'installation

- Structural Stability Measures

- Personal Protective Equipment (PPE) Guidelines

- Electrical Safety Precautions

Warehouse Growth Support

Lire l'étude de cas

Lire l'étude de cas

| Produit | Spécifications | Application |

|---|---|---|

| Électrique | 1.5T, 3m Lift | Entrepôt |

| IC | 3T, 4.5m Lift | Logistique |

| Atteindre | 1T, 5m Lift | Vente au détail |

| Type | Capacité | Adapté |

|---|---|---|

| Acide de plomb | 80V/200Ah | Chariots élévateurs 1-3T |

| Lithium | 48V/400Ah | Chariots élévateurs 1-2T |

| NiMH | 72V/150Ah | Chariots élévateurs 1-2T |

| Type | Taille | Surface |

|---|---|---|

| Solide | 28×9-15 | Rugueux |

| Pneumatique | 23×8-12 | Lisse |

| Polyuréthane | 35×12-19 | Mixte |

| Pièce jointe | Adapté | Fonction |

|---|---|---|

| Déplacement latéral | 1-3T | Flexibilité |

| Rotateur | 2-5T | Allées étroites |

| Contrepoids | Tous | Stabilité |

| Equipement | Fonction | Cas d'utilisation |

|---|---|---|

| Poteau de pare-chocs | Collision | Entrepôt |

| Ceinture de sécurité | Opérateur | Tous les chariots élévateurs |

| Miroir | Visibilité | Tous les chariots élévateurs |

How Akuros Drive-in Racking Can Benefit You

Akuros Drive-in Racking systems are designed to enhance efficiency and safety in warehouse environments. They offer significant advantages that can transform your operations. With their advanced features and robust design, these racks are built to streamline workflows and optimize storage utilization.

Ils offrent des solutions de stockage organisées qui accélèrent la préparation des commandes, l'emballage et le transport des marchandises, minimisant ainsi le travail manuel et accélérant les processus de l'entrepôt. Leur conception peu encombrante et leurs capacités de reconfiguration faciles maximisent l'espace de stockage, ce qui permet une plus grande densité de stockage et une meilleure utilisation de l'espace.

Safety is a paramount concern, and Akuros Drive-in Racking systems are designed with safety in mind. They ensure stable operation in various conditions, reducing accident risks and creating a safer working environment for your team.

De plus, ces rayonnages sont rentables, avec une construction durable qui réduit les dépenses d'exploitation à long terme. Au fur et à mesure que votre entreprise se développe, leur évolutivité et leur flexibilité permettent d'étendre vos solutions de stockage en entrepôt de manière transparente.

| Produit | Spécifications | Application |

|---|---|---|

| Électrique | 1.5T, 3m Lift | Entrepôt |

| IC | 3T, 4.5m Lift | Logistique |

| Atteindre | 1T, 5m Lift | Vente au détail |

| Type | Capacité | Adapté |

|---|---|---|

| Acide de plomb | 80V/200Ah | Chariots élévateurs 1-3T |

| Lithium | 48V/400Ah | Chariots élévateurs 1-2T |

| NiMH | 72V/150Ah | Chariots élévateurs 1-2T |

| Type | Taille | Surface |

|---|---|---|

| Solide | 28×9-15 | Rugueux |

| Pneumatique | 23×8-12 | Lisse |

| Polyuréthane | 35×12-19 | Mixte |

| Pièce jointe | Adapté | Fonction |

|---|---|---|

| Déplacement latéral | 1-3T | Flexibilité |

| Rotateur | 2-5T | Allées étroites |

| Contrepoids | Tous | Stabilité |

| Equipement | Fonction | Cas d'utilisation |

|---|---|---|

| Poteau de pare-chocs | Collision | Entrepôt |

| Ceinture de sécurité | Opérateur | Tous les chariots élévateurs |

| Miroir | Visibilité | Tous les chariots élévateurs |

Akuros Drive-in Racking FAQs

Drive-in racking systems require regular inspections to ensure structural integrity and safety. This includes checking for damage to beams, anchors, and connections. Routine maintenance also involves cleaning and lubricating moving parts, as well as verifying the functionality of any integrated safety features or monitoring systems.

Our Other Product Series

Ordinary Beam Rack

● Features electromagnetic braking for safety.

Rayonnage à double profondeur

● Excellent stability for heavy loads.

● Provides precise control and maneuverability.

● Maximizes storage capacity in limited spaces.

● Supports efficient warehouse space management.

Rayonnage pour allées étroites

● Designed for narrow aisle operations.

● Optimizes storage density in high racks.

● Ensures efficient warehouse space management.

● Reduces picking errors and improves productivity.

Lightweight/Partition Racks

● Flexible storage solutions for a wide range of industries.

● Durable and space-saving, optimized warehouse layout.

● Cost-effective storage solution for lightweight materials.