» Akuros E16 Electric Counterbalance Forklift

Precision Control, Compact Power, and Reliable Performance for Modern Warehousing

Product Overview (Quick Facts)

| Item | Description |

|---|---|

| Product Model | Akuros E16 |

| Truck Type | Three-Wheel Electric Counterbalance Forklift |

| Rated Capacity | 1.6 Ton |

| Drive System | Electric, AC motor technology |

| Steering Configuration | Three-point support design |

| Control System | Fingertip hydraulic control with proportional valve |

| Key Advantage | High maneuverability, precise handling, low operating cost |

| Typical Applications | Warehousing, manufacturing, cold storage, logistics centers |

| Operating Environment | Indoor / semi-indoor industrial environments |

| Operator Focus | Ergonomic, low-fatigue, high-precision operation |

Core Technical Advantages

| Feature Category | Akuros E16 Highlights |

|---|---|

| Fingertip Control | Ergonomic fingertip levers enable precise hydraulic actuation with minimal effort |

| Proportional Valve Technology | Smooth, proportional lifting and tilting for accurate load positioning |

| Compact Design | Optimized chassis for narrow aisles and tight working spaces |

| Stabilité | Three-wheel counterbalance design enhances maneuverability without sacrificing balance |

| Efficacité énergétique | Optimized power management for extended operating hours |

| Operator Comfort | Reduced vibration, intuitive layout, and clear visibility |

| Maintenance | Simplified access to key components, lower lifetime service cost |

Scénarios d'application typiques

| L'industrie | Cas d'utilisation |

|---|---|

| Warehousing & Distribution | Pallet handling in narrow aisles |

| Fabrication | Line-side material supply and finished goods movement |

| Entreposage frigorifique | Reliable electric operation in temperature-controlled environments |

| Retail Logistics | Fast loading and unloading in confined dock areas |

| Traitement des commandes pour le commerce électronique | High-frequency short-distance handling |

Product Description

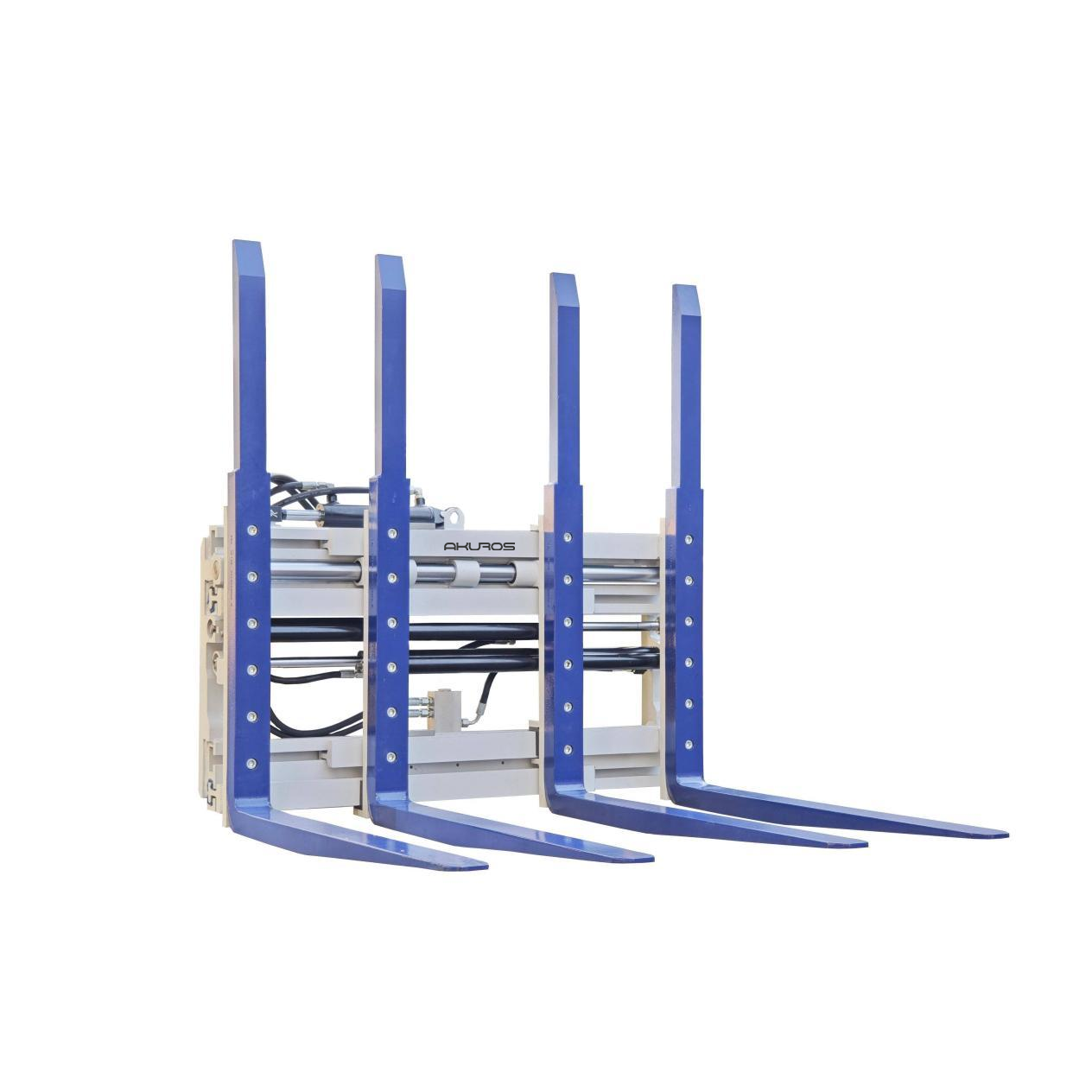

Le Akuros E16 electric chariot élévateur à contrepoids is engineered for operations that demand precision, agility, and reliability in confined working environments. Designed around a compact three-wheel architecture, the E16 delivers outstanding maneuverability while maintaining the stability required for daily industrial handling tasks.

At the core of the E16 is its fingertip hydraulic control system, paired with proportional valve technology. This combination allows operators to perform lifting, lowering, and tilting actions with exceptional smoothness and accuracy. Unlike conventional on/off hydraulic systems, proportional control ensures that fork movement precisely follows operator input—reducing load swing, minimizing positioning errors, and improving safety during stacking operations.

The three-point support configuration significantly reduces the turning radius, making the Akuros E16 especially suitable for narrow aisles, container loading, and dense warehouse layouts. Despite its compact footprint, the forklift maintains excellent load stability, enabling confident handling even during rapid directional changes.

From an operator’s perspective, the E16 emphasizes ergonomic efficiency. Fingertip controls reduce physical strain during long shifts, while the well-balanced chassis and optimized steering geometry improve responsiveness. Clear mast visibility and intuitive control placement help shorten training time and reduce operational errors.

Energy efficiency is another key advantage. The E16’s electric drive system delivers consistent power output with low energy consumption, helping operators achieve longer uptime and reduced operating costs. Combined with simplified maintenance access, the forklift supports a lower total cost of ownership over its service life.

Whether deployed in logistics hubs, manufacturing plants, or temperature-controlled facilities, the Akuros E16 provides a dependable solution for businesses seeking precise material handling with minimal footprint.

Pourquoi choisir l'Akuros E16 ?

-

Precise load positioning enabled by proportional hydraulic control

-

Excellent maneuverability for space-constrained operations

-

Operator-friendly design reduces fatigue and improves productivity

-

Electric drive supports clean, quiet, and energy-efficient operation

-

Proven suitability for multi-shift warehouse environments

Foire aux questions (FAQ)

1. What makes the Akuros E16 different from standard electric forklifts?

The E16 combines a three-wheel counterbalance design with fingertip proportional control, delivering superior maneuverability and precise load handling compared to conventional models.

2. Is the Akuros E16 suitable for narrow aisle warehouses?

Yes. Its compact chassis and reduced turning radius make it ideal for narrow aisles and confined spaces.

3. How does fingertip control improve operation?

Fingertip controls allow smoother, more accurate hydraulic movements, reducing operator fatigue and improving stacking precision.

4. Can the E16 be used in cold storage environments?

The electric drive system performs reliably in temperature-controlled environments, making it suitable for cold storage and food logistics operations.

5. What are the maintenance benefits of the E16?

Simplified component access and electric drivetrain design reduce routine maintenance time and long-term service costs.