In today’s fast-paced logistics environment, warehouses are under constant pressure to move more materials, faster, safer, and with fewer operational costs. While forklifts remain the backbone of internal material handling, the real performance advantage often comes from an area many companies overlook—forklift attachments.

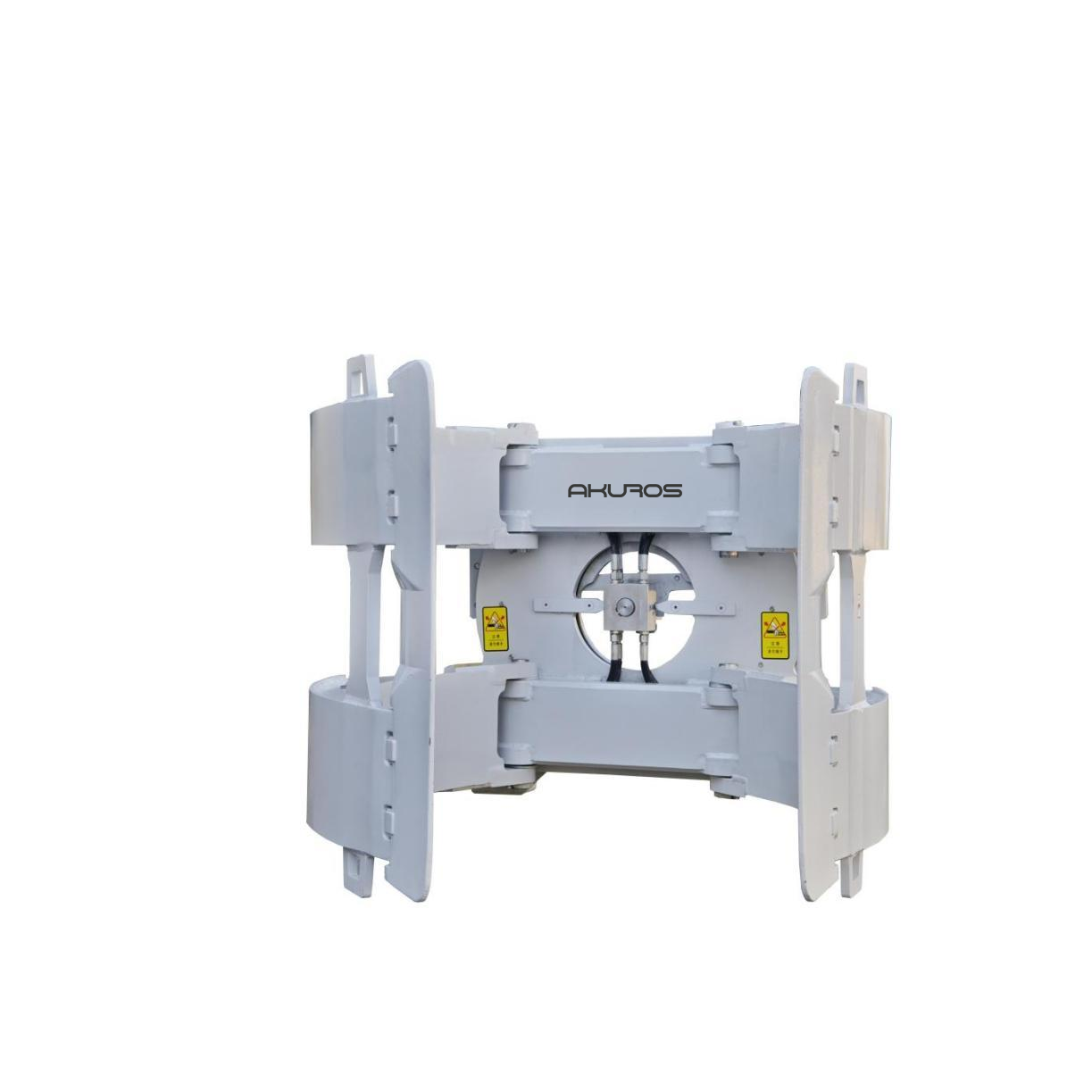

High-quality attachments turn a single forklift into a multi-functional machine capable of doing the work of several specialized vehicles. At Akuros, we design and manufacture a full range of intelligent, durable, and application-focused forklift attachments engineered to improve handling efficiency, reduce product damage, and optimize labor productivity across every industry sector.

This article explains why forklift attachments matter, the performance benefits they unlock, and how choosing the right attachment can completely transform warehouse operations.

1. Forklift Attachments: The Hidden Driver of Efficiency

1. Forklift Attachments: The Hidden Driver of Efficiency

A standard forklift can only lift and transport loads. But once equipped with the right attachment, it can:

-

handle more load types

-

improve productivity per shift

-

reduce manual labor

-

increase operator safety

-

support automated or semi-automated processes

-

reduce damage to pallets, cartons, paper rolls, and soft goods

Attachments essentially extend the capabilities of the forklift fleet, eliminating the need for multiple specialized trucks and enabling warehouses to adapt quickly to different product lines.

2. Key Problems Solved by Forklift Attachments

✔ Lower Product Damage

Attachments such as Carton Clamps, Paper Roll Clampsy Bale Clamps apply uniform pressure designed specifically for delicate or non-palletized goods.

This reduces:

-

crushing

-

edge deformation

-

roll out-of-round damage

-

wrapping tears

Warehouses handling cartons, tissue rolls, or baled materials experience damage reductions of up to 60% when switching from pallets to specialized attachments.

✔ Higher Handling Speed

✔ Higher Handling Speed

With the right attachment, operators can pick, position, rotate, stack, and load products in a single action, reducing handling time per unit and significantly increasing hourly throughput.

For example:

-

A Push-Pull system eliminates pallets in export loading.

-

A Single-Double Pallet Handler allows operators to carry two pallets at once.

-

A Side-Shifting Fork Positioner optimizes maneuvering in tight aisles.

¿El resultado?

Fewer movements, faster cycles, and higher productivity.

✔ Adaptability Across Industries

Each industry has unique material handling challenges. Akuros attachments are used widely in:

-

food & cold-chain (anti-corrosion, stainless steel, IP-rated designs)

-

paper & printing (precision pressure-controlled roll clamps)

-

electronics & manufacturing (soft-handling clamps, exact fork positioning)

-

logistics & e-commerce (multi-pallet handlers for peak-season throughput)

-

recycling & waste (bale clamps, rotating attachments)

Attachments allow a single forklift to switch between tasks without replacing equipment, improving asset utilization.

3. How Akuros Attachments Deliver a Performance Advantage

✔ Engineered for Harsh Environments

Many Akuros attachments—including those used in frozen warehouses, seafood processing, and chemical plants—feature:

-

galvanization

-

stainless steel bearings

-

IP67-grade waterproofing

-

low-temperature hydraulic systems

This ensures reliable operation in -25°C cold storage, dusty production sites, and corrosive environments.

✔ Precision Hydraulics for Smooth, Accurate Handling

Every clamp, fork positioner, and handler uses multi-stage hydraulic control to provide:

-

smooth clamping force

-

precise fork positioning

-

safer handling

-

reduced stress on the forklift mast

This precision directly improves product protection and operator confidence.

✔ Built for Durability & Low Maintenance

Akuros attachments are designed with:

-

reinforced frames

-

high-strength steel

-

wear-resistant sliding materials

-

protected hydraulic hoses

-

modular components for easy maintenance

Result:lower lifetime cost, longer service intervals, and consistent performance.

4. ROI: Why Attachments Reduce Total Ownership Cost

Investing in forklift attachments increases warehouse ROI in several ways:

✔ One forklift can perform multiple tasks

Reducing the need to buy additional specialized trucks.

✔ Less product damage

Especially important for paper rolls, cartons, food storage, and export handling.

✔ Improved labor efficiency

Operators complete tasks faster, reducing shift hours and overtime costs.

✔ Space optimization

Attachments like side-shifters and fork positioners allow better movement in narrow aisles.

✔ Lower pallet usage

Push-Pull systems eliminate thousands of pallets per year, reducing cost and waste.

Warehouses that adopt the right attachments typically see 15–30% efficiency gains within the first months of operation.

5. How to Choose the Right Forklift Attachment

When selecting an attachment, consider:

-

type of goods to handle

-

peso y dimensiones

-

surface sensitivity

-

warehouse aisle width

-

loading/unloading frequency

-

temperature and environment

-

forklift model and compatibility

The Akuros engineering team provides customized solutions, ensuring maximum performance and safety regardless of application.

Conclusion: Small Investment, Big Transformation

Forklift attachments may appear simple compared with entire trucks or automation systems, but they provide some of the highest ROI and fastest efficiency gains in any warehouse operation.

From carton clamps to push-pulls, multi-pallet handlers, paper roll clamps, and fork positioners, Akuros attachments are engineered to help businesses:

-

move materials safer

-

reduce operating costs

-

improve fleet flexibility

-

increase throughput

-

support cold-chain, food, manufacturing, and e-commerce environments

In material handling, the right attachment is often the missing link between a good warehouse and a high-performance one.