In today’s fast-evolving logistics and manufacturing landscape, efficiency is not just an advantage—it is a fundamental requirement. As warehouses shift toward automation, multi-functional equipment, and lean operations, forklift attachments have become essential productivity tools. Beyond simply lifting and transporting goods, forklifts equipped with the right attachments can replace multiple machines, reduce labor intensity, increase throughput, and minimize equipment damage.

Akuros has developed a comprehensive portfolio of advanced forklift attachments, all engineered for high durability, precision performance, and compatibility with global forklift brands. These attachments—including M-Series and K-Series fork positioners, carton clamps, bale clamps, paper roll clamps, push-pull systems, telescopic forks, and more—support industries ranging from food logistics to heavy manufacturing, e-commerce, cold storage, and automated AS/RS facilities.

This guide provides an in-depth technical, functional, and application-focused look at Akuros’ flagship attachment categories—helping businesses understand which attachments deliver the most value and how they elevate overall warehouse performance.

**1. M-Series Sideshifting Fork Positioner

Compact, Lightweight, and Operator-Friendly**

En M-Series fork positioner is designed for operations requiring dynamic fork spacing without sacrificing load stability. Its minimalistic yet robust structure offers significant advantages:

Key Technical Advantages

-

Compact and lightweight structure reduces additional load and energy consumption.

-

Does not increase the lost load distance, preserving the forklift’s rated capacity.

-

Smooth and accurate fork positioning, ideal for handling mixed-size pallets.

-

Fast installation and easy integration with most global forklift brands.

Where the M-Series Excels

-

FMCG distribution centers

-

Retail replenishment

-

Cross-docking operations

-

Food and beverage handling

-

Narrow aisle warehouses

By reducing repositioning errors and improving visibility, the M-Series ensures safer, faster, and more flexible pallet handling.

**2. K-Series Sideshifting Fork Positioner

Maximum Visibility, Minimum Maintenance**

En K-Series represents an upgrade from conventional fork positioners, particularly in ergonomics and maintenance convenience.

Key Technical Advantages

-

Superior visibility through an optimized frame design.

-

Fast installation with universal mounting interfaces.

-

Strong structural rigidity, ensuring precise fork alignment under load.

-

Low-maintenance hydraulic system, reducing downtime.

Ideal Applications

-

Fast-picking warehouse environments

-

Mixed SKU distribution

-

Logistics hubs with high shifts per day

-

Supermarket and retail warehouse operations

Whether operators are loading trucks or organizing warehouse storage, the K-Series supports high-frequency workflows with exceptional durability and ease of control.

**3. Heavy-Duty D-Series Fork Positioner

**3. Heavy-Duty D-Series Fork Positioner

Designed for Industrial-Grade Performance**

En D-Series fork positioner is engineered for demanding workloads that require strength, precision, and long-term reliability.

Key Technical Advantages

-

Reinforced steel structure, suitable for heavy and oversized loads.

-

High-torque hydraulic movement, ensuring stable fork shifting even at maximum loads.

-

Compatible with all major forklift brands.

Best for

-

Steel and metal industries

-

Construction materials

-

Manufacturing plants

-

Ports and heavy logistics

For operations where safety and structural robustness are critical, the D-Series stands as the premier choice.

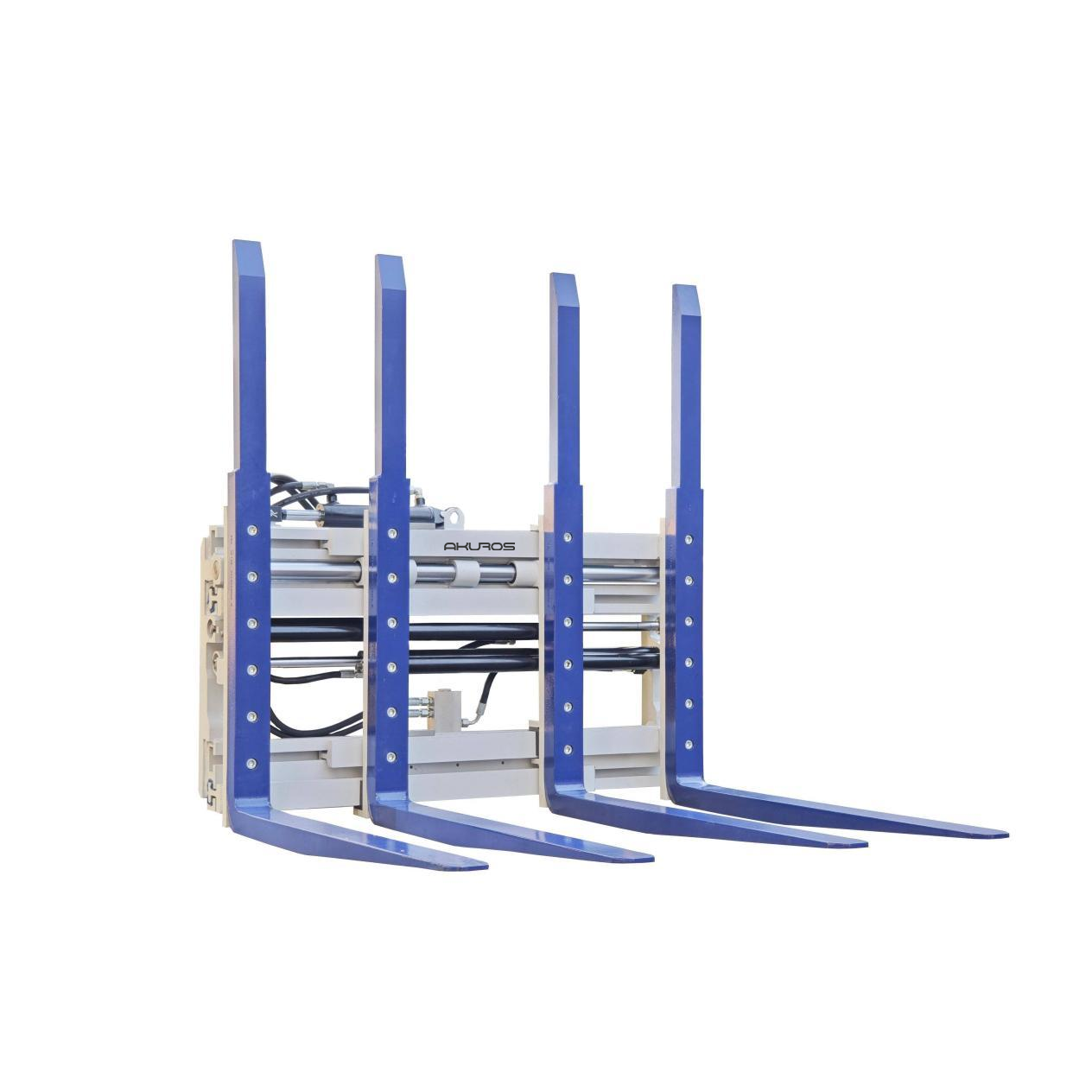

**4. Single-Double Pallet Handler

**4. Single-Double Pallet Handler

Doubling Output Without Expanding Your Fleet**

A standout performer in high-volume industries, the single-double pallet handler enables a forklift to carry one or two pallets simultaneously, instantly doubling throughput.

Key Technical Highlights

-

Optimized frame design offering wide operator visibility.

-

Hydraulic synchronization valve ensures forks move symmetrically.

-

ISO class 2A/3A compatibility, seamless interchangeability.

-

Stable clamping force and precise fork spacing, reducing pallet damage.

Ideal for

-

Beverage production

-

Bottling plants

-

Cold chain distribution

-

Fast-moving consumer goods

-

High-density pallet operations

With a single machine performing the work of two, businesses achieve significantly lower operational costs and faster loading cycles.

**5. Bale, Carton & Paper Roll Clamps

Precision Handling for Non-Palletized Goods**

Non-palletized loads represent some of the most challenging materials to handle safely. Akuros provides specialized clamps designed to protect fragile goods while maintaining operational efficiency.

5.1 Bale Clamp

5.1 Bale Clamp

-

Lightweight yet high-strength design improves lifting efficiency.

-

High visibility frame enhances safety.

-

Load-holding check valve ensures secure clamping.

Best for: cotton, waste paper, textiles, foam materials.

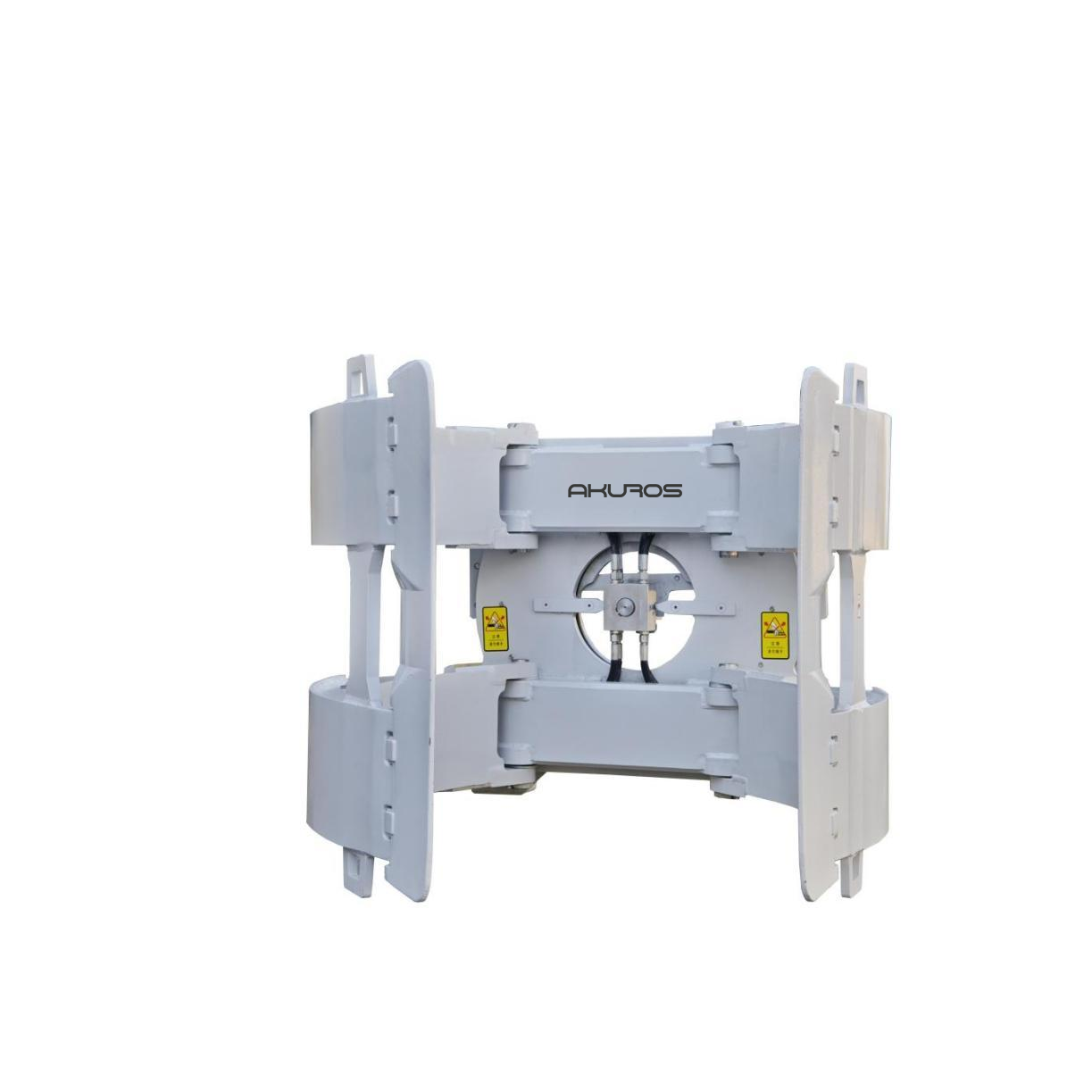

5.2 Carton Clamp

5.2 Carton Clamp

A versatile attachment frequently used in appliance logistics and e-commerce.

-

T-type rail design for smooth, stable movement.

-

Lightweight frame for reduced energy consumption.

-

Balanced clamping force, preventing carton deformation.

-

Multiple arm options suitable for varied carton types.

Ideal for: refrigerators, washing machines, electronics, packaged goods.

5.3 Paper Roll Clamp

5.3 Paper Roll Clamp

Designed specifically for industrial roll handling.

-

Slim, smooth-profile arms minimize roll damage.

-

Pressure relief valve ensures safe, controlled clamping.

-

Excellent rotation control, ideal for precision roll placement.

Industries: printing, packaging, paper mills, logistics.

6. Push-Pull Attachments: A Key Tool for Slip-Sheet Logistics

6. Push-Pull Attachments: A Key Tool for Slip-Sheet Logistics

Push-pull systems allow pallet-free handling—reducing pallet cost, weight, and contamination risk.

Technical Highlights

-

High-strength steel ensures long service life.

-

Wide single-piece baseplate provides strong structural rigidity.

-

Optional sideshift function enhances usability.

-

Quick mounting/disassembly improves workflow flexibility.

Perfect for industries moving toward sustainable, pallet-free operations.

**7. Telescopic Forks

**7. Telescopic Forks

Extending Reach, Maximizing Storage Density**

Telescopic forks are among the most advanced attachments for automated and high-density storage systems.

Key Technical Highlights

-

Synchronized extension/retraction, ensuring high precision.

-

Double-seal hydraulic design prevents oil leakage.

-

Manufactured using German machining technology, ensuring long lifespan.

-

Higher structural rigidity and strength, ideal for AS/RS.

Aplicaciones:

-

High-bay warehouses

-

Shuttle systems

-

Deep lane storage

-

Multi-layer logistics mezzanines

-

Automated pallet transfer operations

Telescopic forks dramatically boost space utilization while supporting next-generation smart warehousing.

8. Why Businesses Trust Akuros Attachments

Akuros’ attachment engineering philosophy focuses on performance, durability, safety, and compatibility. Businesses benefit from:

✔ Increased Operational Efficiency

Faster workflows, reduced machine cycles, improved precision.

✔ Lower Total Cost of Ownership

Fewer equipment failures, less labor dependence, extended component life.

✔ Enhanced Safety

Optimized visibility, stable pressure control, reinforced frames.

✔ Application Versatility

From cold storage to e-commerce to heavy manufacturing.

✔ Compatibility with Major Forklift Brands

Easy integration into existing fleets with minimal downtime.