El picking inteligente empieza aquí: Cómo el preparador de pedidos adecuado puede transformar su almacén

In today’s fast-paced logistics and e-commerce sectors, speed and accuracy aren’t just expectations—they’re survival tools. One of the most vital pieces of equipment that can drastically impact fulfillment operations is the Recogedor de pedidos. From ergonomic design to height-specific picking capabilities, these machines are tailored to make modern warehouses more intelligent, efficient, and scalable.

At Akuros, we believe your Recogedor de pedidos is more than just a tool—it’s your frontline worker for accurate, speedy, and safe order fulfillment. This article serves as your comprehensive guide to understanding what makes a great Recogedor de pedidos, the types available, and how they solve real-world challenges in warehousing.

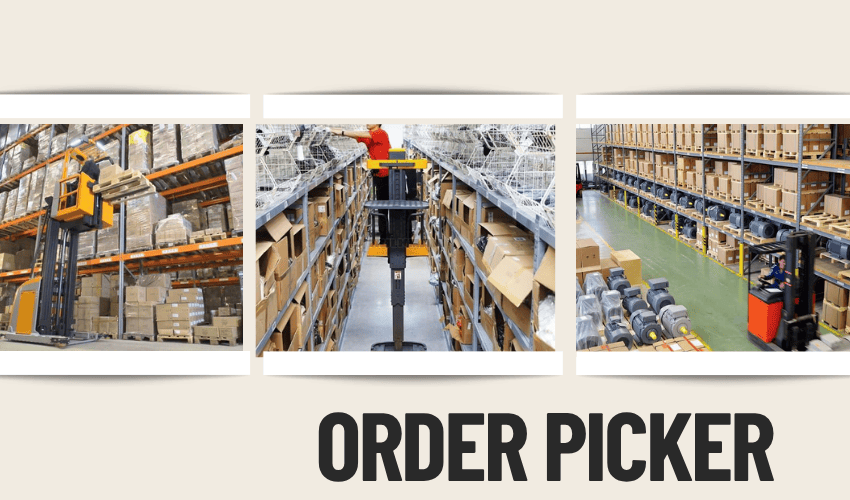

Order Picker for Warehouse

Contenido

- 1 Why Every Smart Warehouse Needs an Order Picker

- 1.1 Real Use-Case: Optimizing a Distribution Center in Korea

- 1.1.1 Key Features That Matter in an Order Picker

- 1.1.2 Choosing the Right Order Picker for Your Warehouse

- 1.1.3 Comparing Order Pickers with Other Lifting Equipment

- 1.1.4 Benefits of Akuros Order Pickers

- 1.1.5 Customer Feedback Snapshot

- 1.1.6 How to Choose the Right Model

- 1.1.7 Emerging Trends in Order Picker Technology

- 1.2 Investing in Smart Picking

- 1.1 Real Use-Case: Optimizing a Distribution Center in Korea

Why Every Smart Warehouse Needs an Order Picker

The growth of e-commerce has transformed how businesses store and retrieve products. Traditional forklifts and manual carts no longer suffice in high-volume, high-density operations. A dedicated Recogedor de pedidos offers:

-

Vertical efficiency – Access upper shelves without ladders or scaffolding.

-

Operator control – Stand-on platforms with ergonomic joysticks reduce fatigue.

-

Picking precision – Narrow aisle navigation allows product-level selection.

-

Increased safety – Emergency stop buttons, harness points, and smart sensors minimize risk.

Warehouses that integrate a well-matched Recogedor de pedidos solution report dramatic improvements in both cycle time and operator safety.

Real Use-Case: Optimizing a Distribution Center in Korea

A leading 3PL provider in South Korea upgraded its conventional picking carts to Akuros mid-level Order Pickers. The impact was immediate:

-

Picking accuracy improved by 42%

-

Order throughput increased by 36%

-

Operator injury rates decreased by 50%

Their new equipment included intuitive control systems, digital displays, and extended reach platforms, making multi-level picking both safe and precise.

Key Features That Matter in an Order Picker

Ergonomic Design

Modern Order Pickers are built with the operator’s body in mind.

-

Intuitive control systems reduce physical fatigue and mental strain.

-

Open visibility zones allow easy identification of SKUs on high racks.

Enhanced Productivity

Speed is important—but accuracy is essential.

-

High-reaching capabilities enable access to upper racking levels (up to 10m).

-

Stable load handling allows movement of medium-weight items securely.

Safety First

With more automation comes more risk. That’s why top-tier Order Pickers vienen con:

-

Múltiples sensores de seguridad y tecnología anticolisión

-

Interruptores de parada de emergencia y plataformas antivuelco

-

Cumplimiento de las normas CE, ANSI e ISO

Choosing the Right Order Picker for Your Warehouse

Exploremos los tipos más comunes y las situaciones de almacén para las que son más adecuados:

| Tipo de recogepedidos | Lo mejor para | Características | Escenarios de aplicación |

|---|---|---|---|

| Recogedor de pedidos de bajo nivel | Almacenamiento en el suelo y en el primer piso | Plataforma transitable, manipulación de cargas ligeras | Supermercados, comercio electrónico |

| Recogedor de pedidos de nivel medio | Recogida hasta 5 metros | Visibilidad mejorada, elevación semiautomática | Almacenes 3PL, piezas de automóvil |

| Preparador de pedidos de alto nivel | Por encima de 6 metros | Mástil telescópico, cabina de elevación del operador | Estanterías de varios niveles, almacenamiento vertical |

| Recogedor de pedidos de pasillo estrecho | Anchura de pasillo inferior a 2,5 m | Horquillas pivotantes, radio de giro reducido | Almacenamiento de alta densidad |

| Recogedor de pedidos eléctrico | Uso en interiores, picking de alta frecuencia | Batería recargable, poco ruidosa | Productos farmacéuticos, logística electrónica |

Comparing Order Pickers with Other Lifting Equipment

| Característica | Recogedor de pedidos | Carretilla elevadora | Carretilla elevadora |

|---|---|---|---|

| Altura de recogida | Hasta 10 m | Limitado | Sólo a nivel del suelo |

| Control del operador | En la plataforma, ergonómico | En cabina | Manual/Eléctrico |

| Seguridad | Alta (varios sensores) | Moderado | Bajo |

| Navegación por pasillos | Excelente en espacios estrechos | Requiere un radio de giro más amplio | Moderado |

| Aplicación | Picking a nivel de artículo | Transporte de palés completos | Pallet repositioning |

Benefits of Akuros Order Pickers

Whether you manage a cold chain, a high-turnover e-commerce warehouse, or an industrial supply store, our Order Pickers deliver:

-

Efficiency across levels: From floor-level picking to top-shelf access

-

Operator-focused design: Every detail crafted for ease-of-use

-

Adaptability: Available in both AC electric and manual assist models

-

Global compliance: Meets ANSI, CE, ISO, and other certifications

Global Order Picker

Customer Feedback Snapshot

“We reduced 1.5 hours from each daily picking cycle after integrating Akuros Order Pickers.”

— Logistics Manager, Thailand

“The intuitive controls helped train new employees 40% faster. Plus, it’s much safer.”

— Warehouse Supervisor, Netherlands

How to Choose the Right Model

Ask yourself:

-

What is my average picking height?

-

Do I need to navigate narrow aisles?

-

How heavy are my average picked items?

-

How many pickers will operate simultaneously?

Your answers help define whether a low-level, mid-level, or high-level Order Picker best suits your operation.

Emerging Trends in Order Picker Technology

Keep an eye on:

-

Telematics integration for real-time performance tracking

-

Hybrid electric systems for longer battery life

-

Automated Order Pickers powered by AI and computer vision

Durable Order Picker

Investing in Smart Picking

Investing in the right Recogedor de pedidos means:

✅ Faster order cycles

✅ Better safety records

✅ Happier warehouse operators

✅ Lower operational costs

In an age of smart warehouses, the Recogedor de pedidos is the unsung hero that turns manual chaos into digital clarity.

Noticias anteriores

Reach Truck Solutions: Maximizing Warehouse Eff...Próximas noticias

Top 7 Advantages of Using Narrow Aisle Racking ...Comparte: