- Trustpilot

Our Automated Solutions

Akuros intelligent solution comprehensively covers the automation, digitalization and intelligent upgrading and transformation from the equipment production line level, workshop level and enterprise level, and is a complete set of comprehensive solutions.

Our automated production capabilities

Strenge Tests

Effizientes Design

Fortschrittliche Fertigung

Flexible Dienstleistungen

Partial automated solutions gallery

| Produkt | Spezifikation | Anmeldung |

|---|---|---|

| Elektrisch | 1.5T, 3m Hub | Lagerhaus |

| IC | 3T, 4.5m Hub | Logistik |

| Erreichen Sie | 1T, 5m Hub | Einzelhandel |

| Typ | Kapazität | Geeignet |

|---|---|---|

| Bleisäure | 80V/200Ah | 1-3T Gabelstapler |

| Lithium | 48V/400Ah | 1-2T Gabelstapler |

| NiMH | 72V/150Ah | 1-2T Gabelstapler |

| Typ | Größe | Oberfläche |

|---|---|---|

| Solide | 28×9-15 | Raue |

| Pneumatisch | 23×8-12 | Glatt |

| Polyurethan | 35×12-19 | Gemischt |

| Anlage | Geeignet | Funktion |

|---|---|---|

| Seitenschieber | 1-3T | Flexibilität |

| Rotator | 2-5T | Schmale Gänge |

| Gegengewicht | Alle | Stabilität |

| Ausrüstung | Funktion | Anwendungsfall |

|---|---|---|

| Prellbock | Kollision | Lagerhaus |

| Sicherheitsgurt | Betreiber | Alle Gabelstapler |

| Spiegel | Sichtbarkeit | Alle Gabelstapler |

Get your automated solution now

- Send us a message with your needs, and we'll recommend the best automated solution for your operation.

- Every unit is tested before delivery to guarantee safety, reliability, and long - term use.

- We offer factory - direct prices and flexible options to meet different budgets and application needs.

- Our technical team provides complete after - sales service, including installation guidance, spare parts, and long - term maintenance support - so you can operate with confidence.

Senden Sie Ihren individuellen Bedarf

Automated Manufacturing and Operation Process

Konzeptionelle Gestaltung

defining automated solution specs and features.

Erstellung von Projekten

Detaillierter technischer Entwurf und Erstellung eines Prototyps.

Herstellung

Production of components and assembly of the automated equipment.

Qualitätssicherung

Rigorous testing to ensure the automated solution meets all quality standards.

Logistik

Planung und Durchführung des Vertriebsprozesses.

Kundenschulung

Providing training to ensure safe and effective operation of the automated equipment.

Der Akuros-Standard - gleichbleibende Qualität, jedes Mal

Entwurfskontrolle

Streng nach Ihrem tatsächlichen Platzbedarf entworfen, ohne Platz zu verschwenden.

Qualitätskontrolle

Wir garantieren, dass jedes Produkt, das wir Ihnen liefern, Ihren Anforderungen voll und ganz entspricht.

Versandkontrolle

Unter Gewährleistung der Qualität verpacken und versenden wir die Waren in kürzester Zeit zum Hafen.

Spezialisierte Industrien

E-commerce Fulfillment Centers

Manufacturing Workshops

Cold Chain Logistics

Pharmaceutical Warehouses

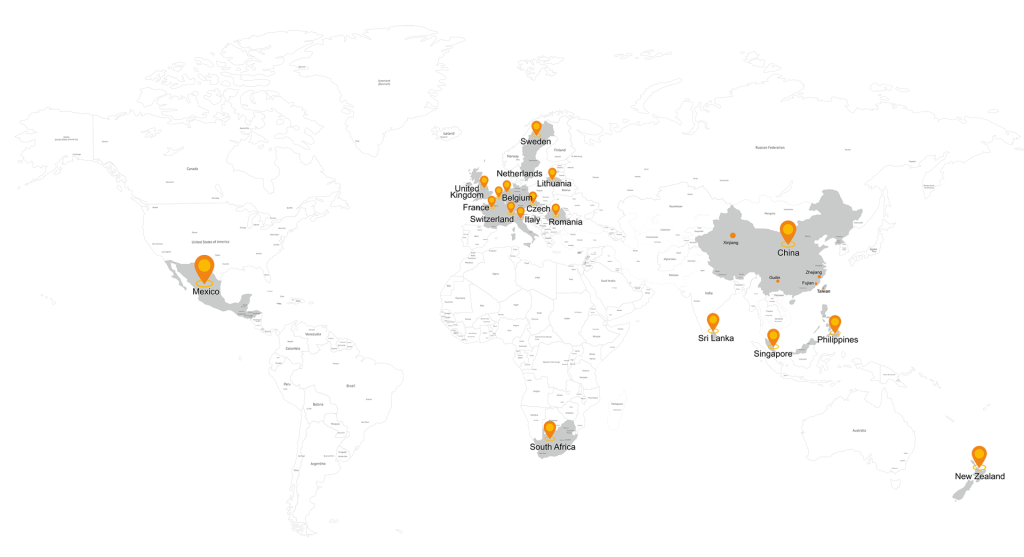

Akuros Global Market

Akuros Vorteil

Einige unserer Produktionspartner

- Established: 2010

- Fähigkeiten: Advanced sensor manufacturing for automated equipment, precision measurement and monitoring systems

- Machines: 20 high-precision sensor calibration machines, automated sensor testing stations

- Expertise: Specializing in creating highly sensitive and reliable sensors for warehouse automation systems, ensuring accurate data collection and equipment operation monitoring.

- Established: 2014

- Fähigkeiten: Development of sophisticated control software and hardware for automation equipment

- Machines: 15 automated software testing platforms, 10 hardware-in-the-loop testing systems

- Specialization: Producing cutting-edge control systems that enable seamless integration and precise control of various automated components in a warehouse setting.

- Established: 2011

- Fähigkeiten: Manufacturing of robotic arms and automated guided vehicles (AGVs) for material handling

- Machines: 30 robotic assembly lines, 10 AGV testing tracks

- Expertise: Focused on creating flexible and efficient industrial robots and AGVs that can adapt to different warehouse layouts and operational requirements.

- Established: 2013

- Fähigkeiten: Full system integration of automated warehouse solutions, including software and hardware coordination

- Machines: 25 system integration testing stations, 15 simulation platforms

- Specialization: Expertise in combining various automated components into a cohesive system, ensuring smooth workflow and optimal performance in complex warehouse environments.

- Established: 2015

- Fähigkeiten: Development of energy-efficient power systems for automated equipment, including battery technology and energy management systems

- Machines: 20 battery testing and assembly lines, 10 energy simulation platforms

- Expertise: Committed to creating sustainable and energy-efficient power solutions that reduce operational costs and environmental impact for automated warehouse systems.

| Produkt | Spezifikation | Anmeldung |

|---|---|---|

| Elektrisch | 1.5T, 3m Hub | Lagerhaus |

| IC | 3T, 4.5m Hub | Logistik |

| Erreichen Sie | 1T, 5m Hub | Einzelhandel |

| Typ | Kapazität | Geeignet |

|---|---|---|

| Bleisäure | 80V/200Ah | 1-3T Gabelstapler |

| Lithium | 48V/400Ah | 1-2T Gabelstapler |

| NiMH | 72V/150Ah | 1-2T Gabelstapler |

| Typ | Größe | Oberfläche |

|---|---|---|

| Solide | 28×9-15 | Raue |

| Pneumatisch | 23×8-12 | Glatt |

| Polyurethan | 35×12-19 | Gemischt |

| Anlage | Geeignet | Funktion |

|---|---|---|

| Seitenschieber | 1-3T | Flexibilität |

| Rotator | 2-5T | Schmale Gänge |

| Gegengewicht | Alle | Stabilität |

| Ausrüstung | Funktion | Anwendungsfall |

|---|---|---|

| Prellbock | Kollision | Lagerhaus |

| Sicherheitsgurt | Betreiber | Alle Gabelstapler |

| Spiegel | Sichtbarkeit | Alle Gabelstapler |

Based on 985 reviews

- Trustpilot

Verbesserte Lagereffizienz

Rationalisierter Lagerbetrieb

Economical Automated Solutions

The Akuros Automated Solutions Handbook

More resources for Akuros automated solutions

Einführende Leitfäden

- Understanding Akuros Automation Basics

- Einführung in den Gabelstaplerbetrieb

- Fundamentals of Automation Maintenance

Design-Leitfäden

- Key Design Considerations for Automated Solutions

- Designing Automation Control Interfaces

- Automation Safety Design Guidelines

Anwendungen

- Warehousing Automation Applications

- Manufacturing Automation Applications

- Logistics Automation Applications

Leitlinien für die Verwendung

- Automation Operation Manual

- Troubleshooting Automation Issues

- Optimizing Automation Performance

Verbesserung der Lagereffizienz

Fallstudie lesen

Fallstudie lesen

Fallstudie lesen

Fallstudie lesen

Fallstudie lesen

| Produkt | Spezifikation | Anmeldung |

|---|---|---|

| Elektrisch | 1.5T, 3m Hub | Lagerhaus |

| IC | 3T, 4.5m Hub | Logistik |

| Erreichen Sie | 1T, 5m Hub | Einzelhandel |

| Typ | Kapazität | Geeignet |

|---|---|---|

| Bleisäure | 80V/200Ah | 1-3T Gabelstapler |

| Lithium | 48V/400Ah | 1-2T Gabelstapler |

| NiMH | 72V/150Ah | 1-2T Gabelstapler |

| Typ | Größe | Oberfläche |

|---|---|---|

| Solide | 28×9-15 | Raue |

| Pneumatisch | 23×8-12 | Glatt |

| Polyurethan | 35×12-19 | Gemischt |

| Anlage | Geeignet | Funktion |

|---|---|---|

| Seitenschieber | 1-3T | Flexibilität |

| Rotator | 2-5T | Schmale Gänge |

| Gegengewicht | Alle | Stabilität |

| Ausrüstung | Funktion | Anwendungsfall |

|---|---|---|

| Prellbock | Kollision | Lagerhaus |

| Sicherheitsgurt | Betreiber | Alle Gabelstapler |

| Spiegel | Sichtbarkeit | Alle Gabelstapler |

What can you achieve with Akuros automated solutions?

- Erweiterung des Lagers :Our automated solutions allow for faster loading, unloading, stacking, and transport of goods, significantly increasing the speed of warehouse operations and reducing manual labor.

- Verbesserung der Effizienz :With high – reach capabilities and models designed for narrow aisles, our automated equipment helps businesses make better use of vertical and horizontal space, allowing for higher storage density.

- Verbesserung der Sicherheit :Equipped with advanced safety features and designed for stable operation, our automated solutions reduce the risk of accidents, helping businesses maintain a safer and more compliant working environment.

- Kostenreduzierung :With energy – efficient motors, electric drive options, and low maintenance requirements, our automated equipment helps lower long – term ownership and daily operational costs.

- Produktivitätssteigerung :As your business scales, our automated solutions offer the performance, reliability, and customization options you need to expand operations smoothly and sustainably.

| Produkt | Spezifikation | Anmeldung |

|---|---|---|

| Elektrisch | 1.5T, 3m Hub | Lagerhaus |

| IC | 3T, 4.5m Hub | Logistik |

| Erreichen Sie | 1T, 5m Hub | Einzelhandel |

| Typ | Kapazität | Geeignet |

|---|---|---|

| Bleisäure | 80V/200Ah | 1-3T Gabelstapler |

| Lithium | 48V/400Ah | 1-2T Gabelstapler |

| NiMH | 72V/150Ah | 1-2T Gabelstapler |

| Typ | Größe | Oberfläche |

|---|---|---|

| Solide | 28×9-15 | Raue |

| Pneumatisch | 23×8-12 | Glatt |

| Polyurethan | 35×12-19 | Gemischt |

| Anlage | Geeignet | Funktion |

|---|---|---|

| Seitenschieber | 1-3T | Flexibilität |

| Rotator | 2-5T | Schmale Gänge |

| Gegengewicht | Alle | Stabilität |

| Ausrüstung | Funktion | Anwendungsfall |

|---|---|---|

| Prellbock | Kollision | Lagerhaus |

| Sicherheitsgurt | Betreiber | Alle Gabelstapler |

| Spiegel | Sichtbarkeit | Alle Gabelstapler |