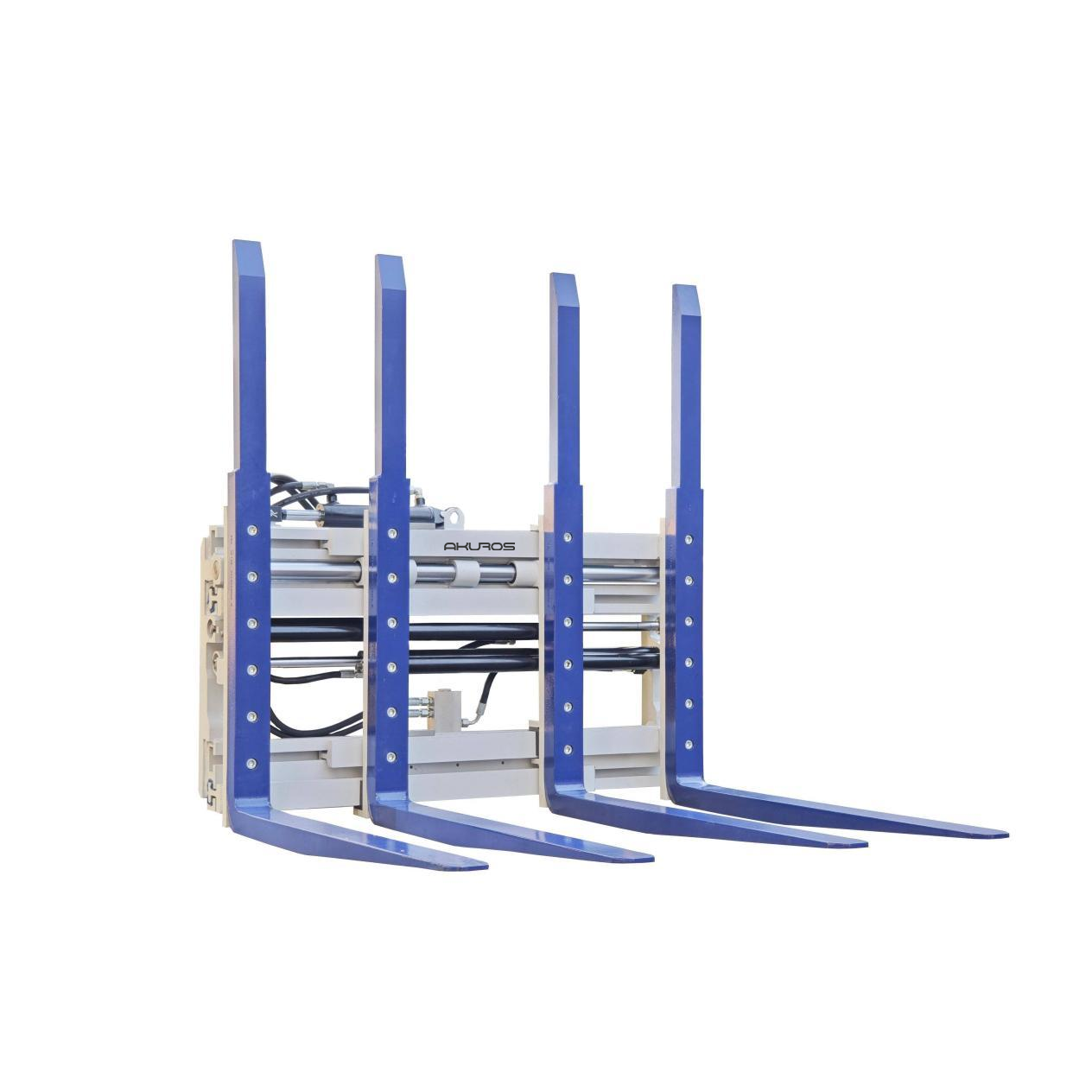

» F-Series Bale Clamp (Rail-Guided Type)

Rail-Guided Precision for High-Stability Bale Handling

|

|

Product Positioning Overview

Before talking about performance, bale clamp buyers care about one thing first:

Is this attachment structurally reliable enough for long-term, high-load operation?

The following table outlines the core structural logic of the مشبك البالات من الفئة F (النوع الموجه بالسكك الحديدية) and why it differs from conventional hydraulic-only clamp designs.

Structural & Functional Overview (Rail-Guided Design)

| Aspect | مشبك البالات من الفئة F (النوع الموجه بالسكك الحديدية) | Conventional Bale Clamp |

|---|---|---|

| Arm Movement Control | Mechanical rail-guided synchronization ensures parallel arm travel | Dependent mainly on hydraulic balance |

| Load Stability | Consistent gripping force across full arm stroke | Force variation under uneven loads |

| Alignment Accuracy | High precision during stacking and container loading | Higher risk of lateral deviation |

| Structural Stress Distribution | Load distributed via guide rails and reinforced frame | Stress concentrated on hydraulic joints |

| Long-Term Wear | Reduced uneven wear on arms and bearings | Faster wear due to arm misalignment |

| Operator Handling Feel | Smooth, predictable engagement | Requires frequent correction |

This rail-guided structure allows the F-Series to maintain repeatable handling behavior, even when bale density, size, or surface friction varies.

Why Rail-Guided Bale Handling Improves Operational Consistency

In high-density bale operations, instability is rarely caused by lifting capacity alone.

The real issue is microscopic misalignment that compounds over thousands of cycles.

By integrating a rail-guided mechanism into the clamp architecture, the F-Series physically constrains arm movement along a defined path. This eliminates the subtle arm drift commonly seen in standard designs and ensures symmetrical load engagement from the first contact to full lift.

For operations handling paper, textile, or recycled material bales, this directly reduces:

-

Product deformation

-

Stack misalignment

-

Corrective operator movements

The outcome is not just smoother handling—but measurably lower operational variability.

Application-Oriented Performance Design

The F-Series Bale Clamp (Rail-Guided Type) is engineered for environments where load consistency cannot be assumed, but safety and efficiency must remain constant.

Typical application scenarios include high-compression paper bales, textile and fiber bales, recyclable material blocks, and export-oriented bale handling where stacking precision affects container utilization.

In these environments, the rail-guided system maintains structural integrity while allowing hydraulic responsiveness to remain fast and controllable.

Structural Reliability Built for Long-Term Use

Unlike designs that rely solely on hydraulic synchronization, the F-Series uses its guide rails as a load-sharing component, not just a positioning aid. This reduces torsional forces on the arms and frame, extending service life under continuous-duty cycles.

For fleet operators and warehouse managers, this translates into fewer unplanned stoppages and more predictable maintenance planning.

Frequently Asked Questions (FAQ)

What is the main advantage of a rail-guided bale clamp?

The rail-guided system ensures synchronized arm movement, improving load stability and reducing uneven wear compared to hydraulic-only designs.

Is the F-Series suitable for different bale sizes?

Yes. The rail-guided architecture allows consistent gripping performance across varying bale widths and densities without compromising alignment.

Does rail guidance reduce operator error?

Indirectly, yes. Predictable arm movement reduces the need for corrective handling, making operation more intuitive and repeatable.

What industries commonly use rail-guided bale clamps?

Paper recycling, textile processing, waste management, and logistics operations handling compressed or high-density bales.

Can the F-Series be mounted on existing forklifts?

The clamp is designed for standard forklift integration, subject to capacity and hydraulic compatibility.

How does the rail-guided design affect maintenance?

It reduces uneven mechanical stress, which can extend service intervals and lower long-term maintenance costs.